Patents

Literature

58results about How to "Prevent slump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

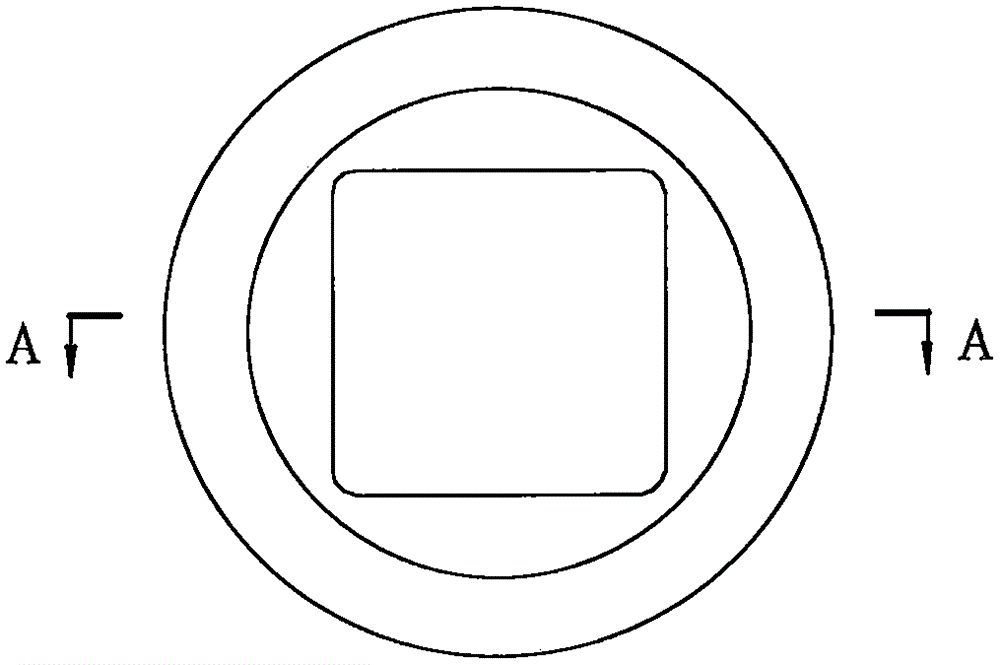

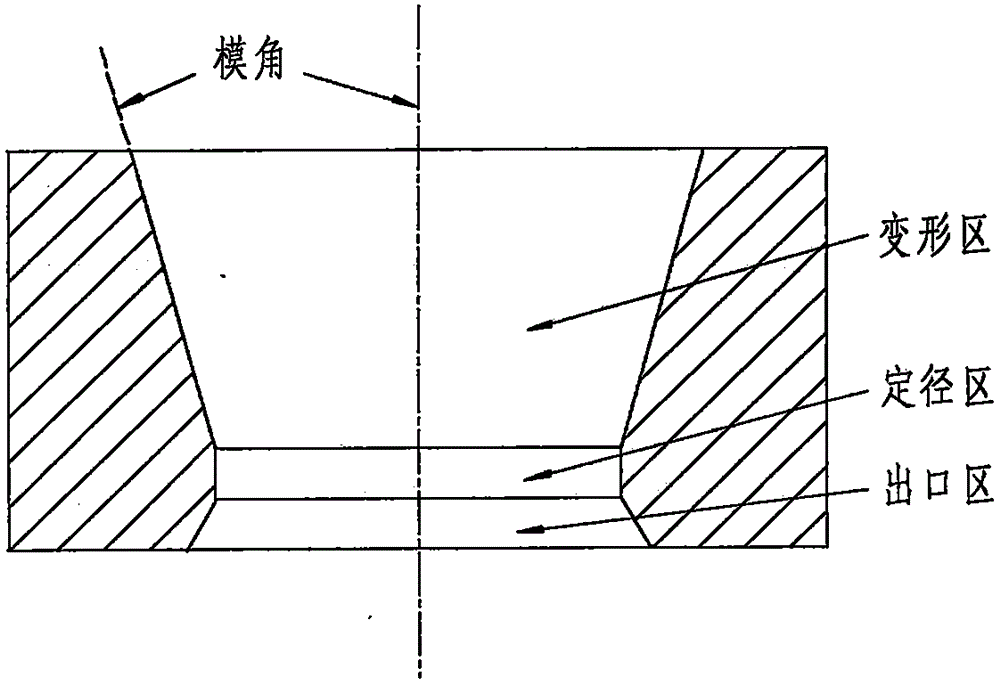

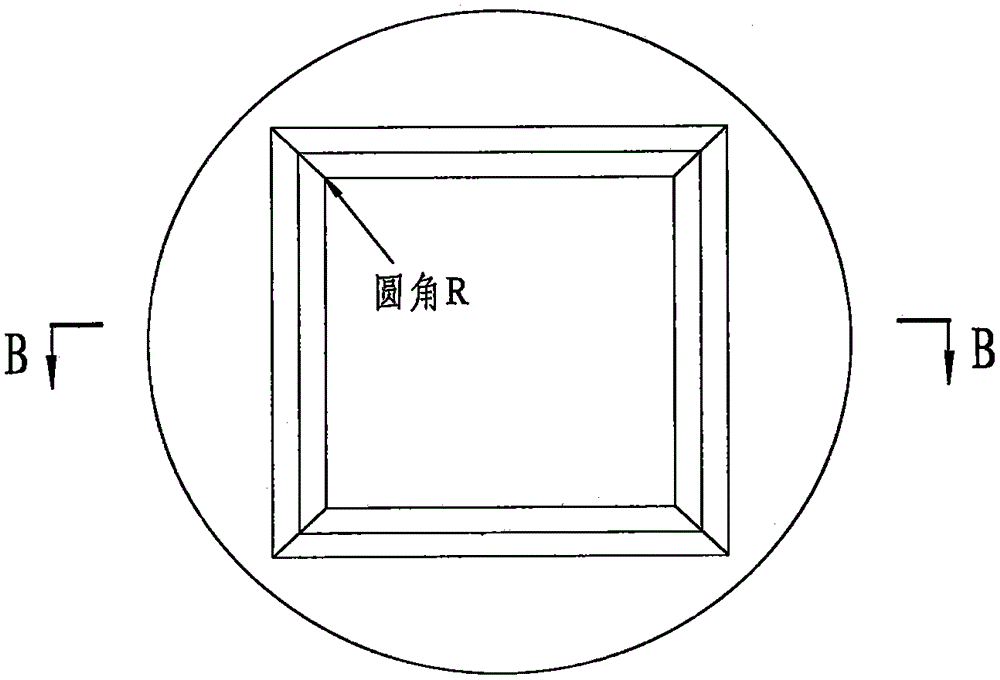

Preparation process of red copper square pipe material

ActiveCN105562456APrevent oxidationReduce operational processingDrawing mandrelsDrawing diesSurface oxidationChain type

The invention provides a preparation process of a red copper square pipe material. The process comprises the following flow processes of casting, cast ingot sawing and cutting, water seal extrusion, sawing and cutting, straightening, rolling, chain type drawbench circular drawing, circular transition to square pipe material hollow pulling, square pipe material hollow pulling, shaping drawing, finishing, bright annealing and packaging; the diameter shaping drawing is firstly performed after the rolling; the transition to the square pipe material is realized; the diameter shaping hollow pulling is performed; finally, a finished product is fed onto a core head to be subjected to shaping drawing; the goal that the radius R of the circular corner is gradually reduced until the radius R conforms to the requirement is achieved; the outer dimension center part back arching is avoided; the inner dimension is enabled to conform to the requirements; the water seal decrustation processing mode is used in the extrusion process; the pipe blank surface oxidation can be prevented; the process processing process is reduced; the product quality is further ensured.

Owner:中铝洛阳铜加工有限公司

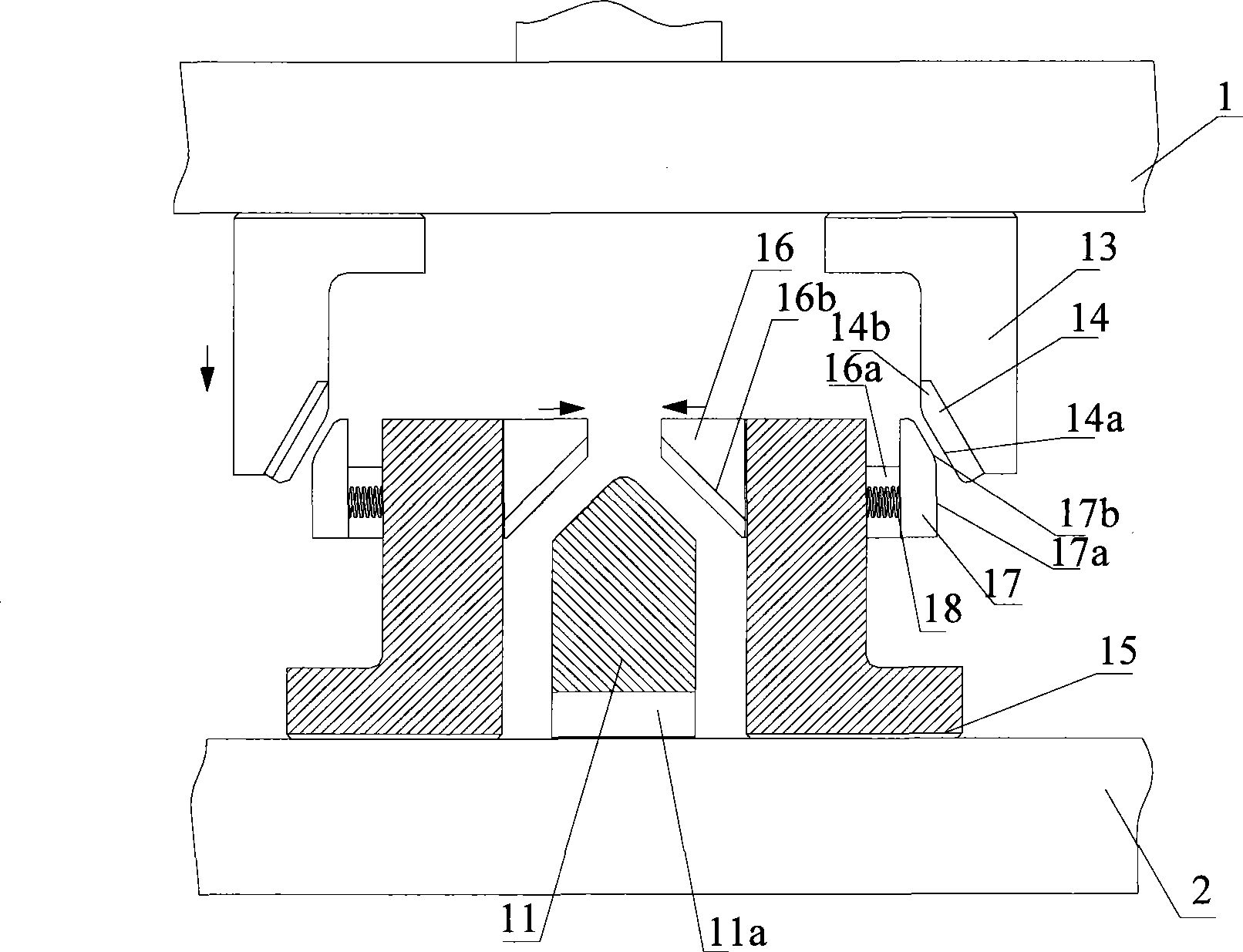

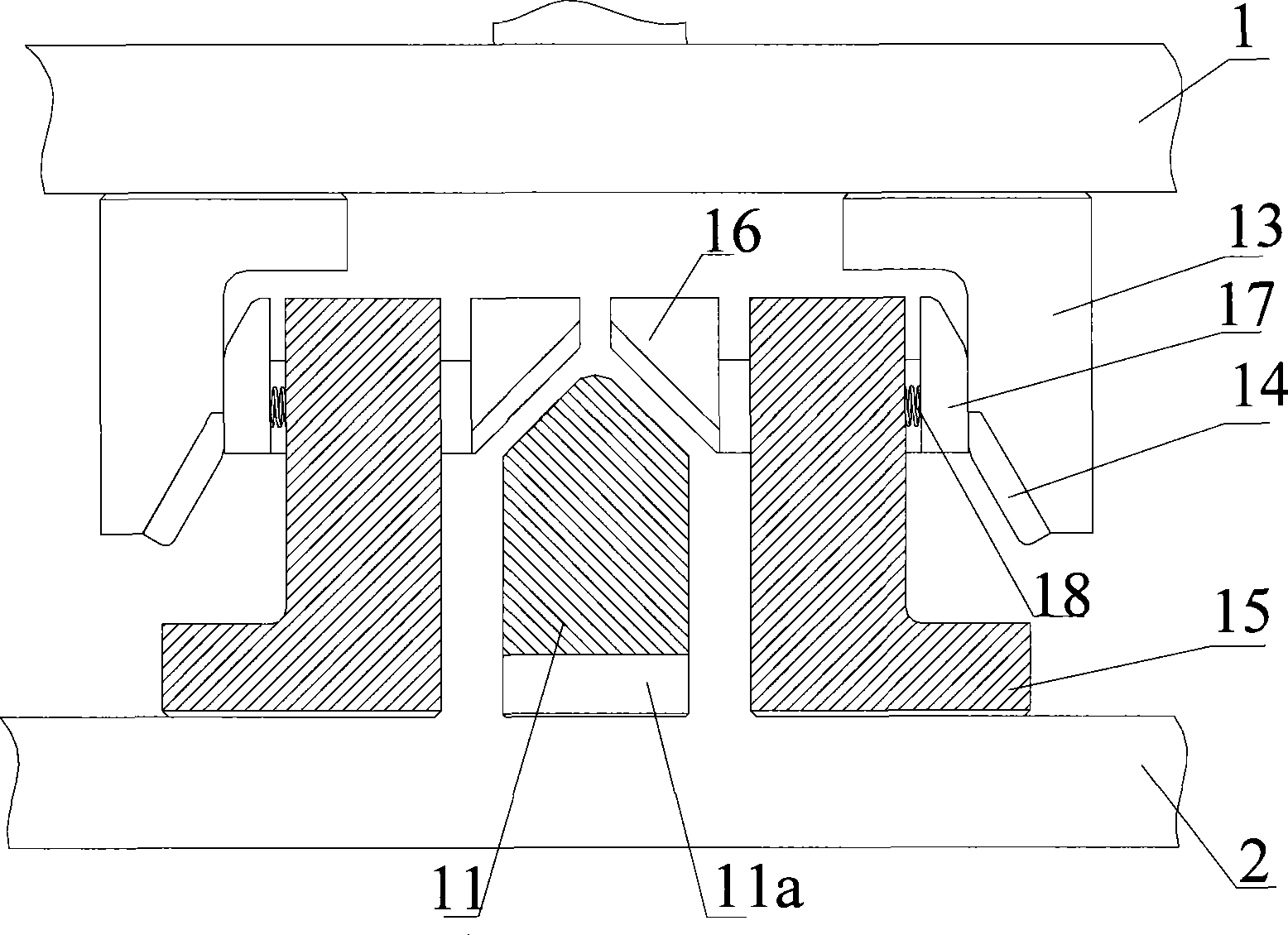

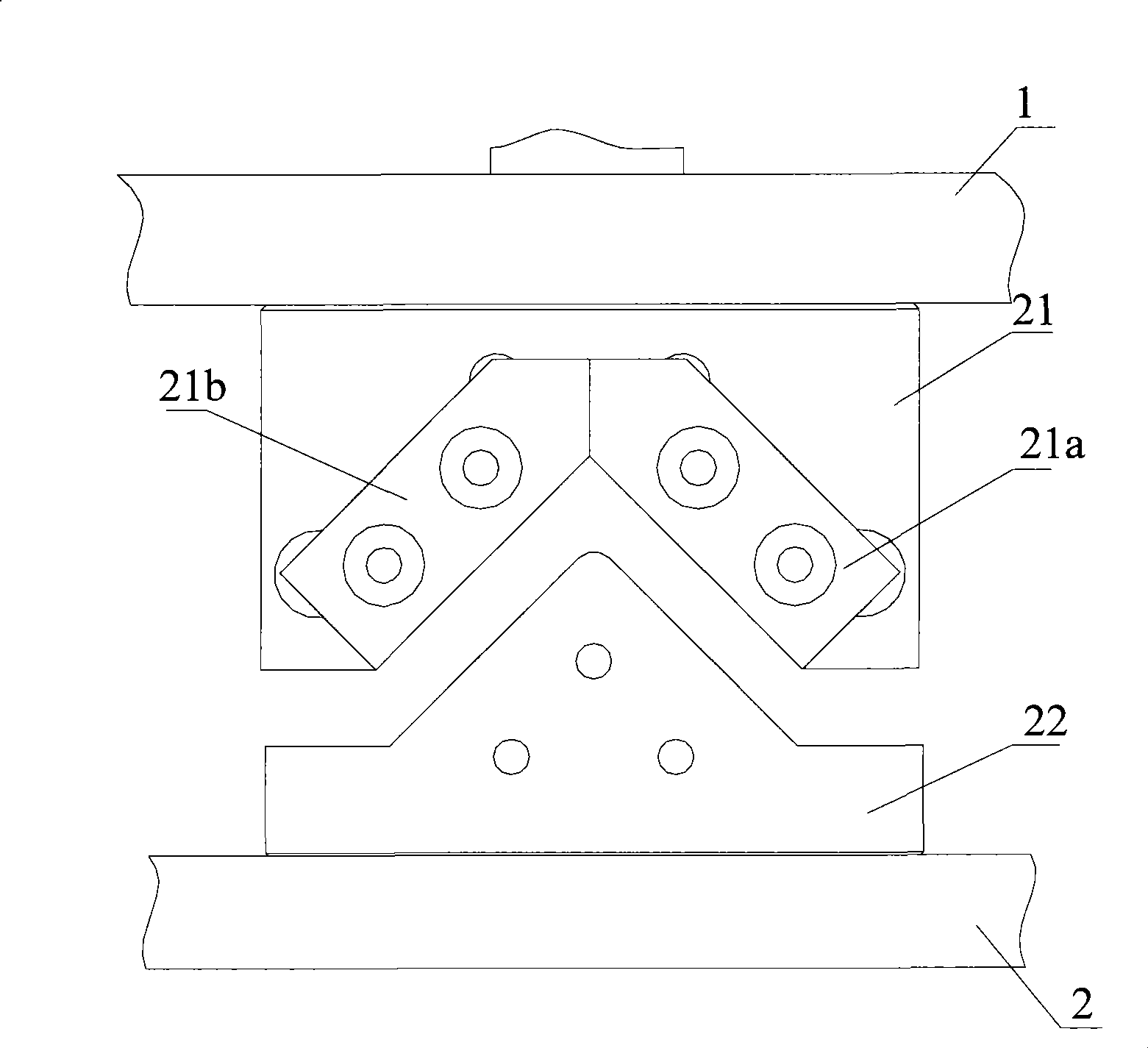

Material-pressing mechanism for angle-bar breaking mold and angle-bar breaking mold

ActiveCN101412060AAvoid skewPrevent tamperingShearing machine accessoriesShearing toolsEngineeringMechanical engineering

The invention discloses a material clamping structure for an angle iron cutting die, which comprises a pair of clamping components which relatively slide to clamp two outer surfaces of an angle iron, a pair of clamping component brackets supporting the clamping components to slide and a material support base supporting the angle iron, wherein the material support base is arranged between the two clamping components; the material calmping structure also comprises a driving structure pushing the clamping components to relatively slide along the direction of the angle iron to clamp the angle iron and a resetting structure pushing the clamping components to slide away from the angle iron; according to the material clamping structure provided by the invention, the material support base has effects of supporting and piloting the angle iron blank material, by the relatively sliding clamping components clamping the two outer surfaces of the angle iron, the angle iron is prevented from inclination while the angle iron is cut, so the formation of a sunk angle on the cutting surface is avoided.

Owner:CRRC QIQIHAR ROLLING CO LTD +1

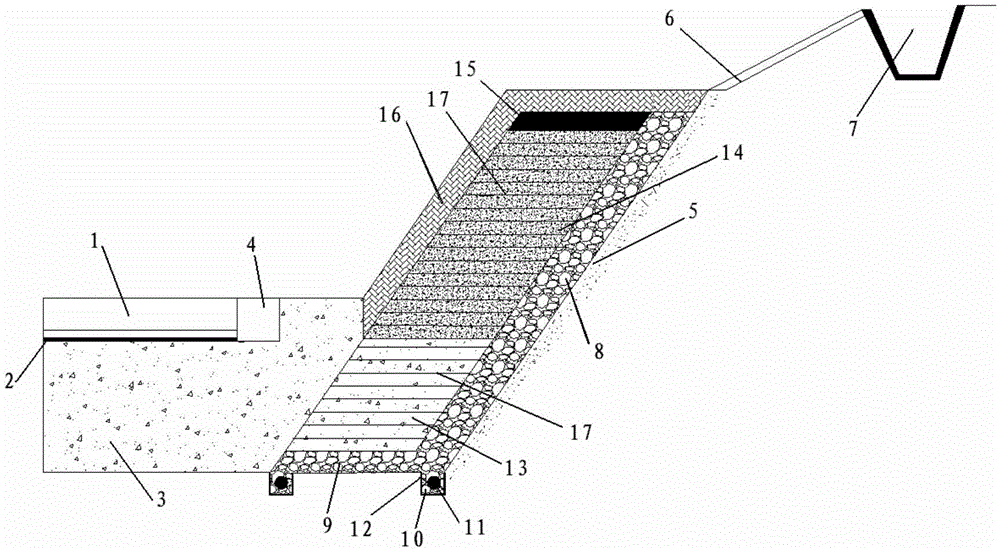

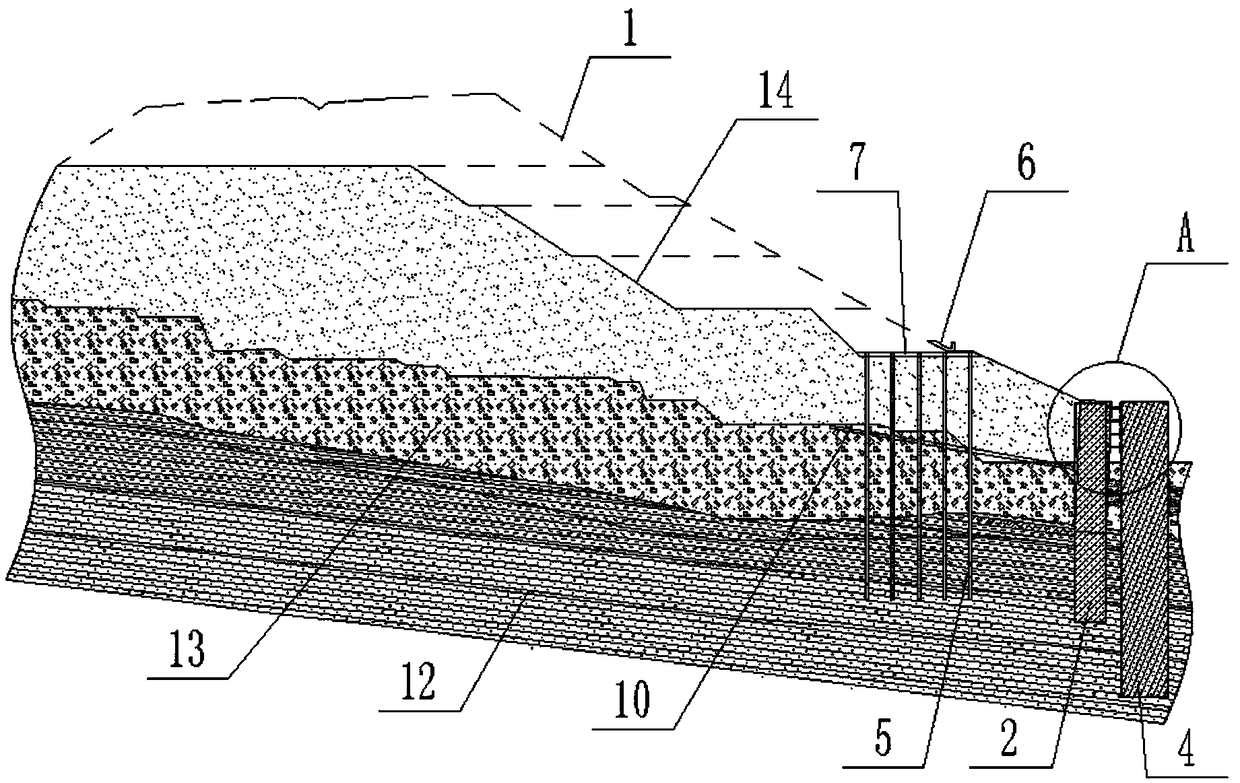

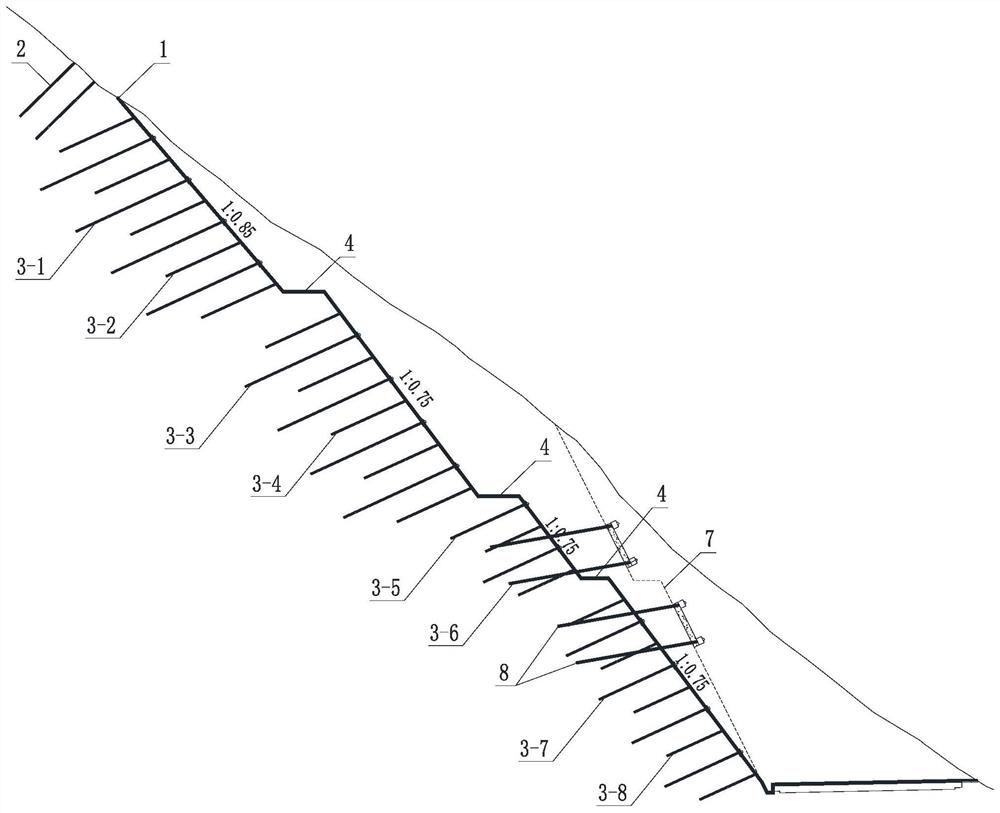

Expansive soil cutting structure and construction method thereof

InactiveCN105569058ARealize moisturizing and anti-seepageReduce hygroscopic swellingPaving gutters/kerbsClimate change adaptationWater dischargeChipseal

The invention discloses an expansive soil cutting structure. The expansive soil cutting structure comprises a pavement, waterproof geotextile and a roadbed which are in sequential arrangement from top to bottom, wherein a side slope provided with an intercepting ditch on the top is arranged on the side surface of the roadbed; anti-seeping geotextile is arranged between the side slope and the intercepting ditch; the slope surface of the side slope is provided with a side slope water seeping layer; a basic water seeping layer, a gravel soil layer, an expensive soil layer and a non-expensive clay layer are arranged between the side slope water seeping layer and the roadbed; the bottom of the basic water seeping layer is provided with at least one seeping ditch; a two-cloth one-film sealing layer and a water discharge pipe with holes are arranged in the seeping ditch; and a geogrid is arranged in the gravel soil layer and the expensive soil layer. A construction method comprises the following steps of performing side slope overexcavation; digging the bottom foundation of the basic water seeping layer; digging the seeping ditch; laying the two-cloth one-film sealing layer, and distributing the water discharge pipe; filling and building a basic water seeping layer and the side slope water seeping layer; filling and building the gravel soil layer and the expensive soil layer; trimming the slope surface of the side slope, and laying the planting soil layer; and arranging the intercepting ditch and the anti-seeping geotextile. The expansive soil cutting structure and the construction method well solves the road repair problems in an expansive soil region, and great popularization values are realized.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

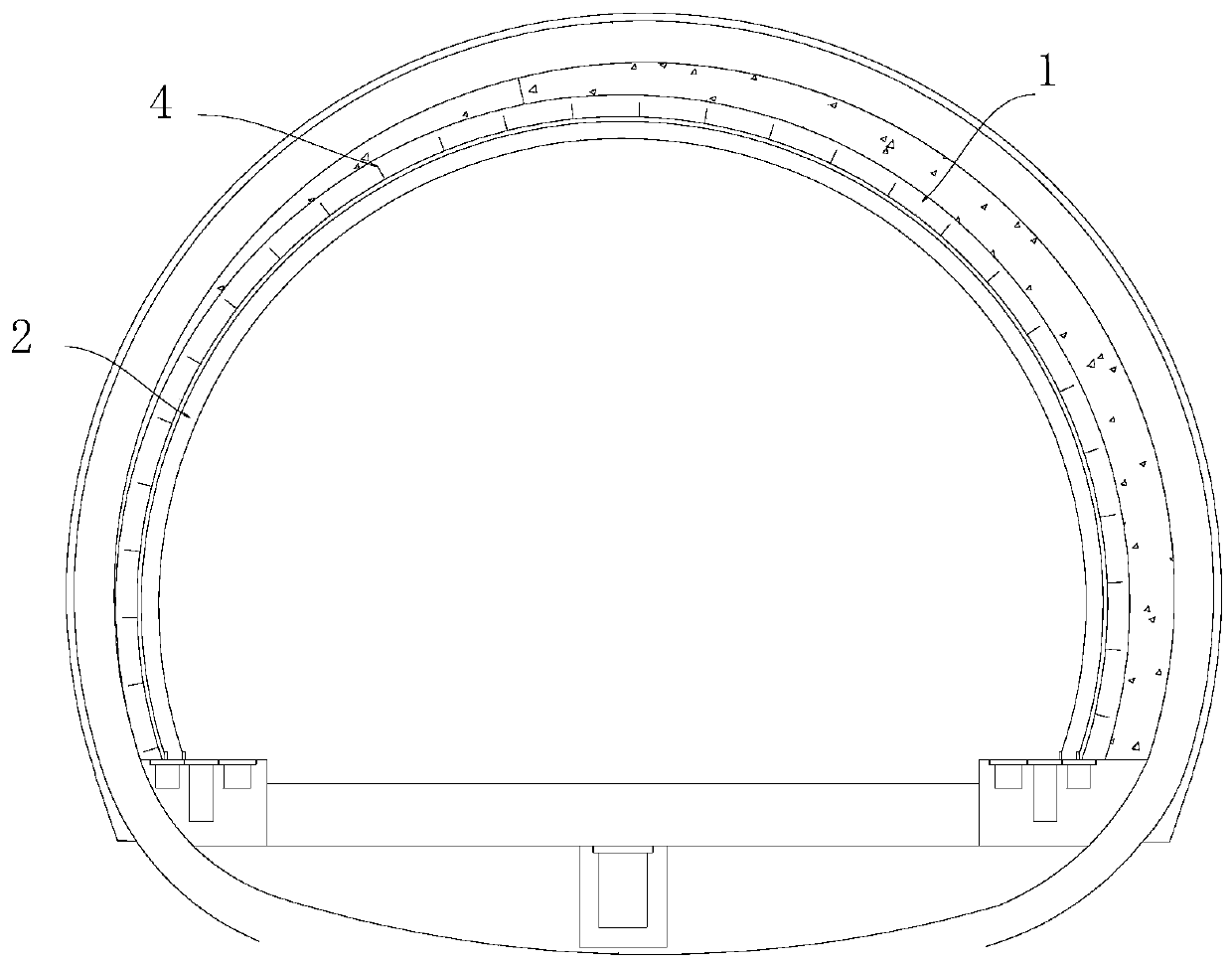

Method for constructing tunnel with low-half cross section being dry powder and fine sand layers

ActiveCN102650210AReduce disturbanceReasonable construction methodUnderground chambersTunnel liningSubsidenceSafety risk

The invention particularly relates to a method for constructing a tunnel with a low-half cross section being dry powder and fine sand layers, which solves the problems of slow construction progress and large safety risk which exist in the existing tunnel construction, and comprises the steps of: a, performing forepoling after survey lofting; b, digging out an arc pilot tunnel, immediately and firstly spraying concrete, and constructing primary anchor-plaster retaining; c, constructing an advanced horizontal jet grouting pile as well as a slant jet grouting pile; d, separately excavating a middle step according to an upper part and a lower part; e, constructing the slant jet grouting pile on a lower step; f, separately excavating the lower step according to the upper part and the lower part; g, excavating a tunnel bottom from the left side and the right side of the tunnel in a subsection way for anchor-plaster retaining; and h, constructing an inverted arch after excavating the reserved core soil, wherein the construction of the inverted arch closely follows the lower step all the time, and then, constructing secondary lining. The method plays the role of controlling the convergence and subsidence of the primary anchor-plaster retaining; and moreover, the disturbance to the fine sand layers is reduced, the subsidence of the tunnel is effectively controlled, the extruded placement of a tunnel face is strictly regulated, and the deformation of the tunnel face is controlled.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

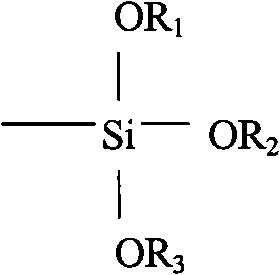

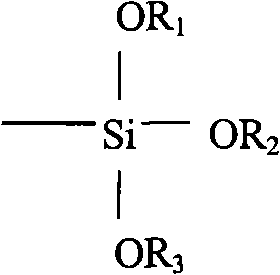

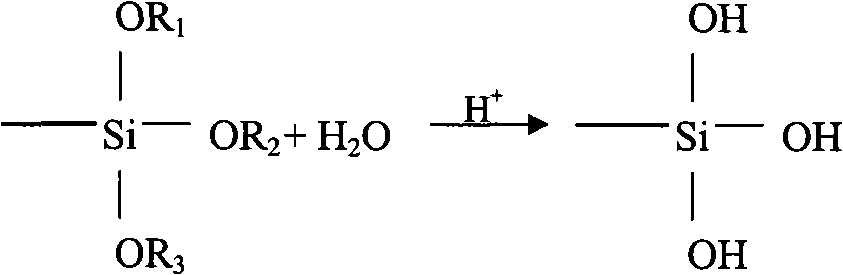

UV B-stageable, moisture curable composition useful for rapid electronic device assembly

InactiveCN101405360AQuick assemblyPrevent slumpEster polymer adhesivesOrganic non-macromolecular adhesiveAcrylic resinAdhesive

The invention provides an adhesive composition which is useful for electronic assembly comprising a photopolymerizable acrylic resin containing polymerizable acrylate, a moisture-curable resin including an alkoxy or acyloxy silane terminated polymer, a photoinitiator for initiating polymerization of the acrylate, and a photoacid generator for catalyzing a moisture curing reaction of the alkoxy or acyloxy silane terminated polymer. Also provided are assemblies including such adhesives, such as electronic assemblies and radio frequency identification tags.

Owner:3M INNOVATIVE PROPERTIES CO

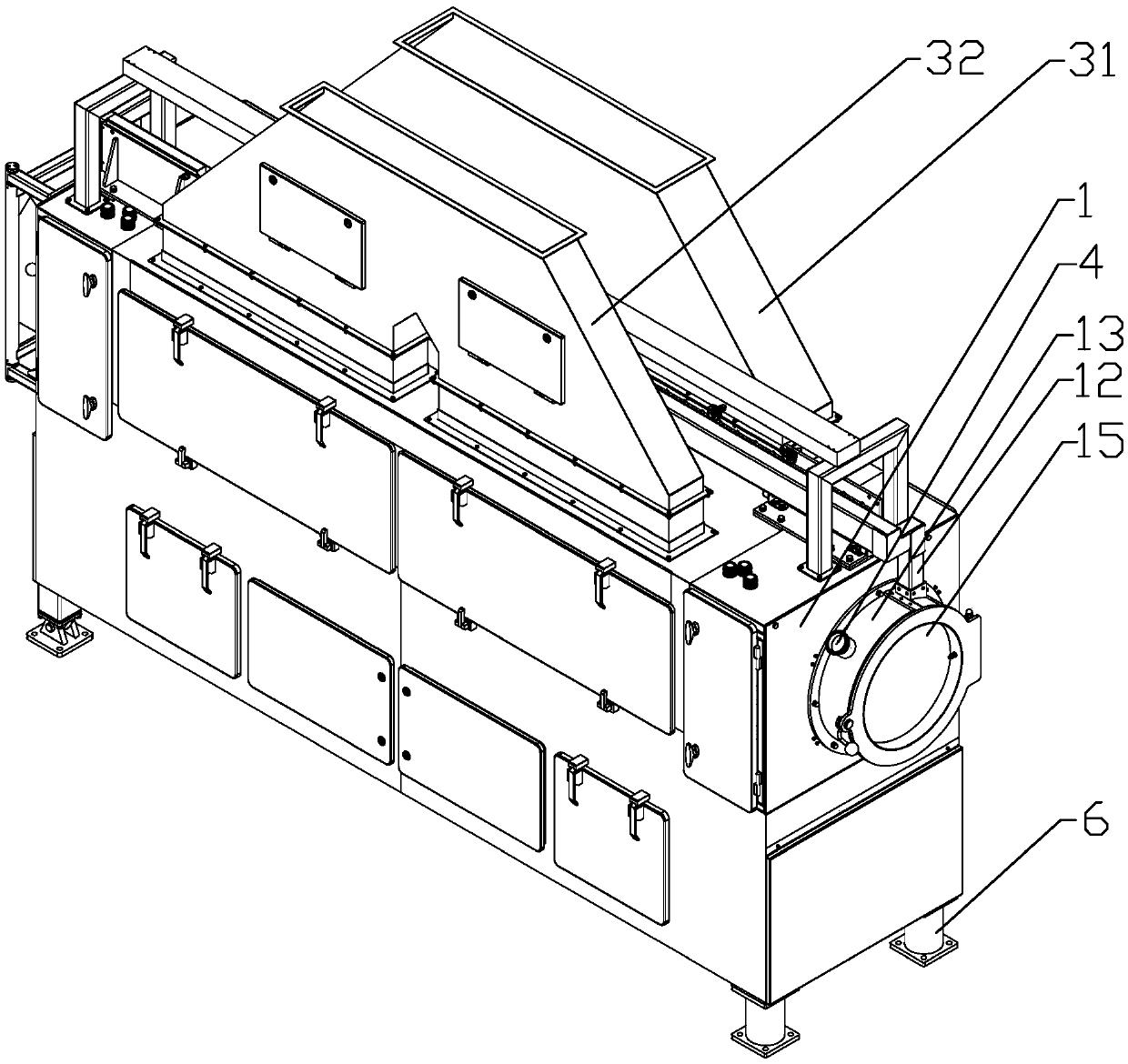

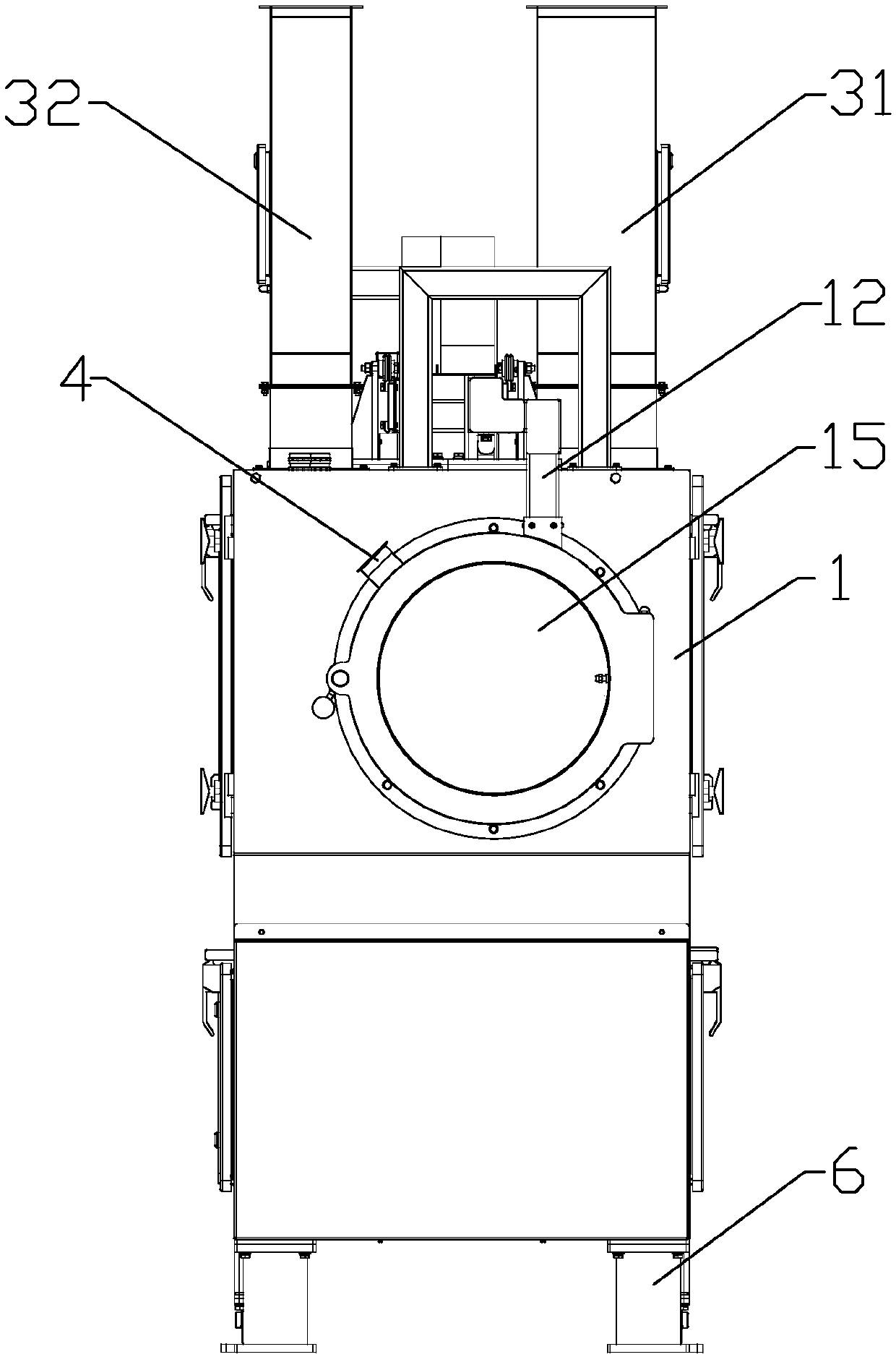

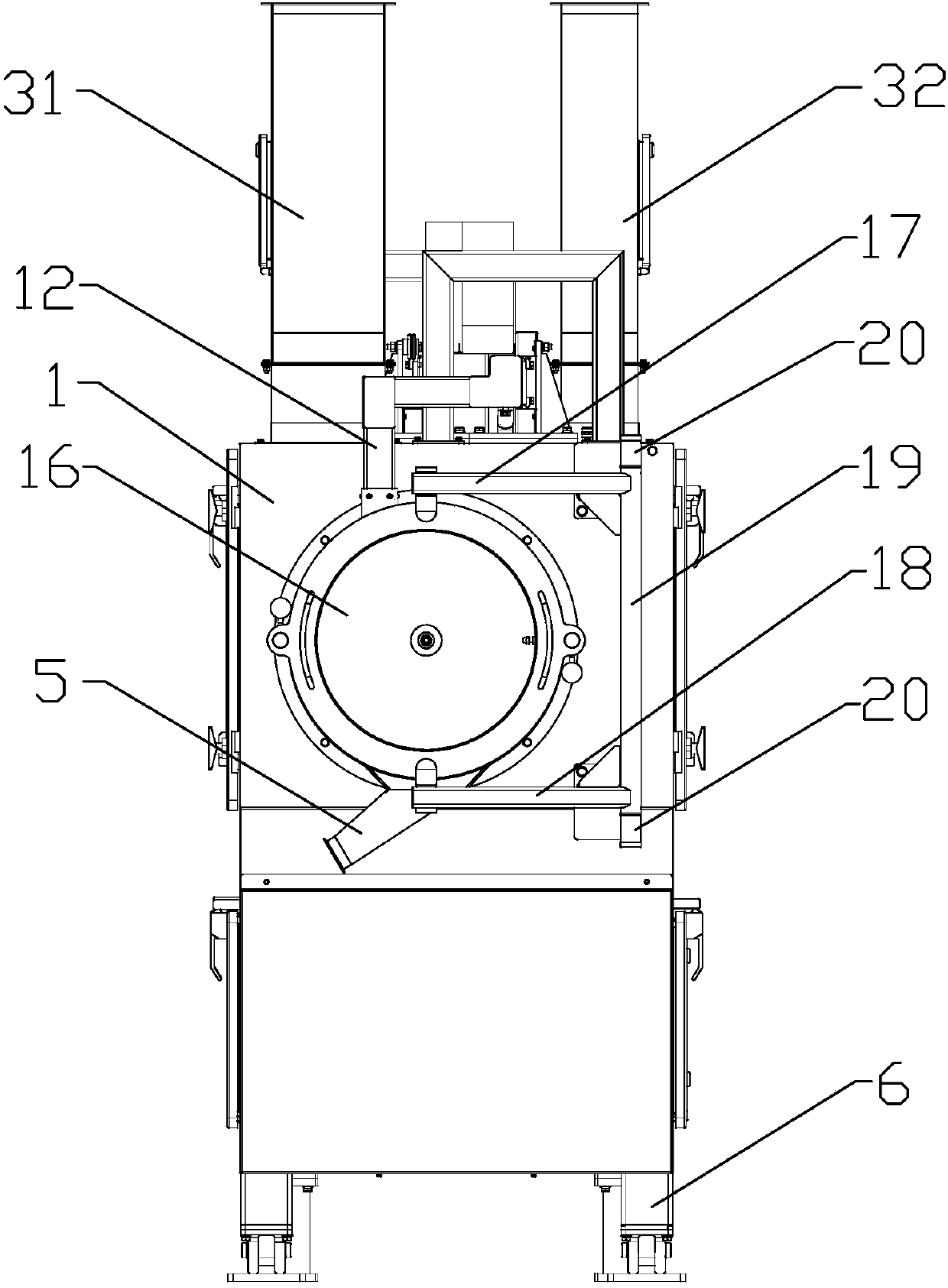

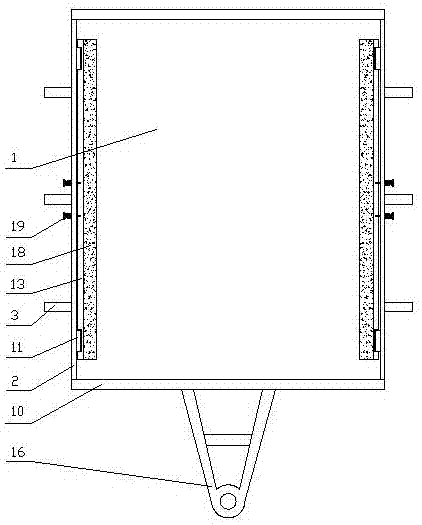

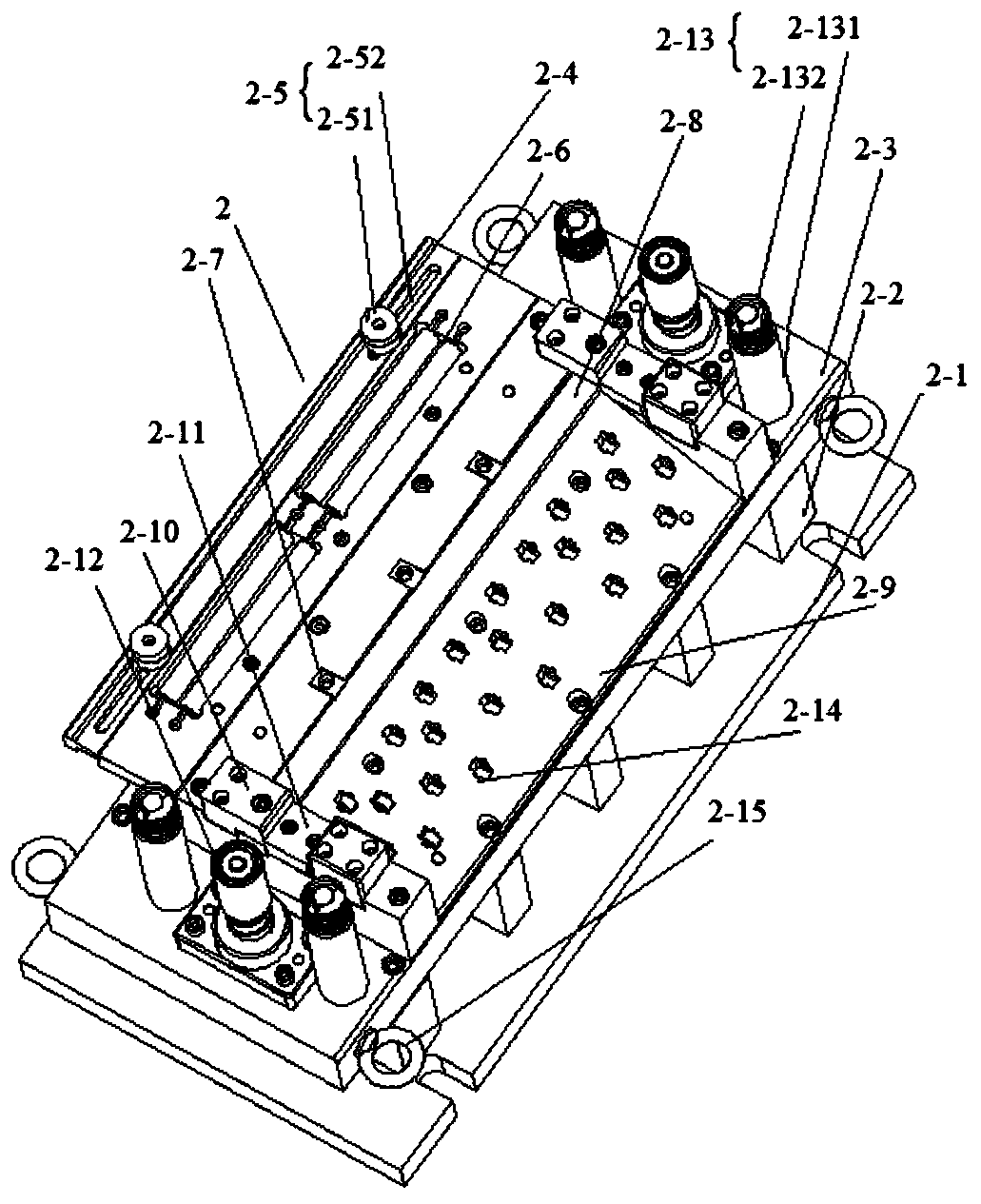

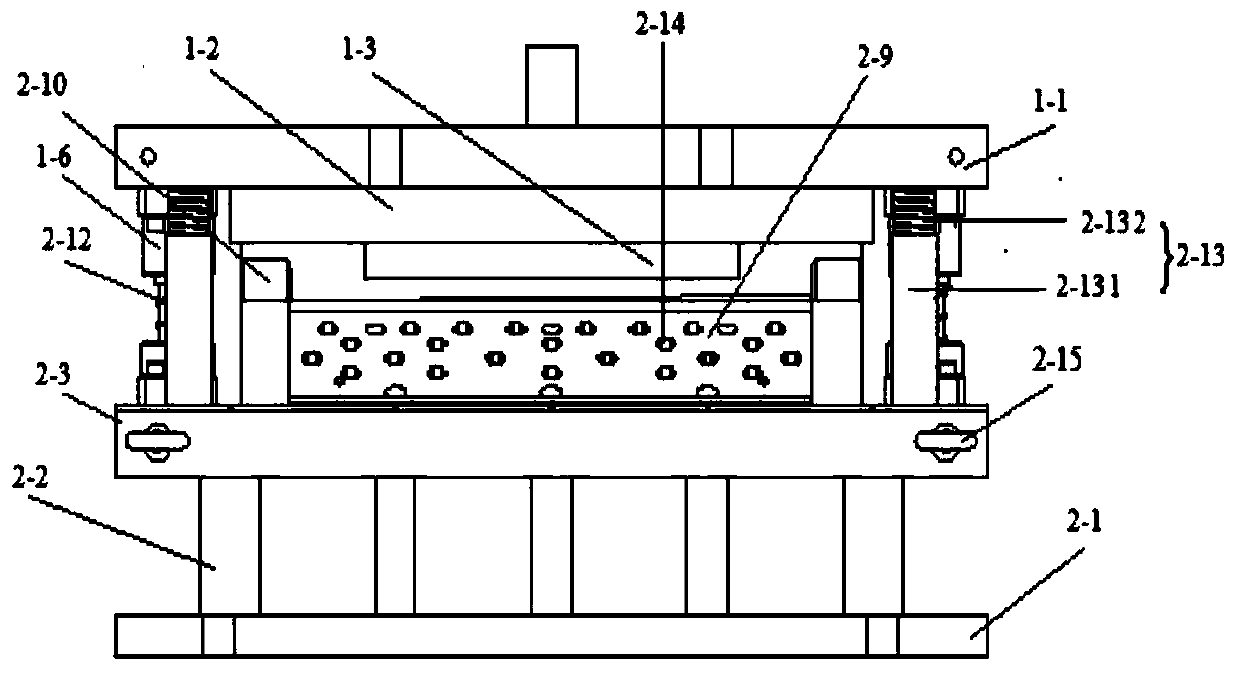

Continuous coating machine and continuous coating method with continuous coating machine

ActiveCN107744167AShort timeReduce energy consumptionPharmaceutical product form changeFood coatingProcess engineeringMechanical engineering

The invention provides a continuous coating machine and a continuous coating method with the continuous coating machine, and relates to a coating machine and a coating method. In order to solve the problems that when a conventional coating machine is used for coating production of massive materials, the time consumption is high, the energy consumption is high, and the production efficiency is nothigh, the invention provides the continuous coating machine. A coating roller is a slab-sided cylinder with two opened ends, and is horizontally mounted in a machine body in a rotating and sealing manner, and through holes are densely distributed in the wall of the coating roller; a feed pipe is arranged at the front end of the machine body, and a discharge pipe is arranged at the rear end of themachine body; and support legs are mounted at four corners of the bottom end of the machine body, and an air cylinder capable of controlling the lifting of the machine body and the coating roller is vertically mounted in two support legs at the front end of the machine body. The coating roller is used for continuously feeding and discharging materials, in the process that the materials advance tothe outlet of the coating roller from the inlet of the coating roller, the coating is completed, and continuous coating production of the massive materials is realized; and besides, the production energy consumption is rationalized, zero consumption during production is realized, and the continuous coating machine is used for coating the materials.

Owner:NANO PHARM TECH MACHINERY EQUIP

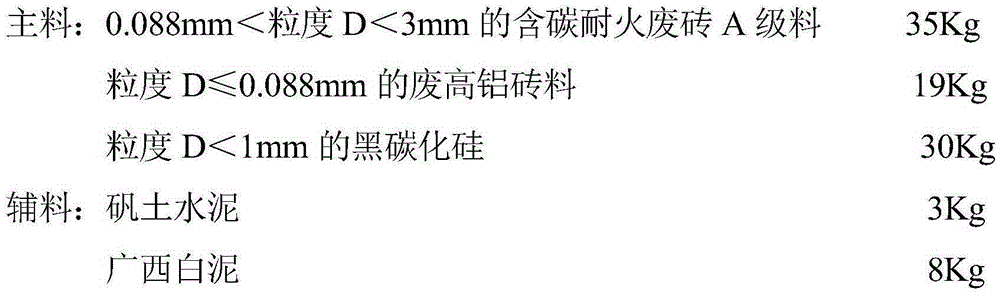

Slag anti-adhesion coating for hot metal ladle

The invention discloses a slag anti-adhesion coating for a hot metal ladle. The slag anti-adhesion coating consists of the following components in percentages by weight: 35-70wt% of carbonaceous fireproof waste brick A-level materials, 10-35wt% of waste high-aluminum brick materials, 5-30wt% of black silicon carbide, 3-8wt% of aluminous cement, 3-8wt% of Guangxi white clay, 0.1-2wt% of carboxymethyl cellulose sodium, 0.1-1wt% of sodium tripolyphosphate, 0.1-1wt% of organic explosion-proof fibers, and 0.01-1wt% of quick lime. According to the slag anti-adhesion coating for the hot metal ladle disclosed by the invention, the preparation process is simple; besides, in the construction project of slag anti-adhesion treatment for the hot metal ladle, the slag anti-adhesion coating has the characteristics of being simple in construction, excellent in slag anti-adhesion property, high in sintering intensity, low in cost and the like, and is obvious in economic benefit and social benefit.

Owner:WUGANG REFRACTORY CO LTD

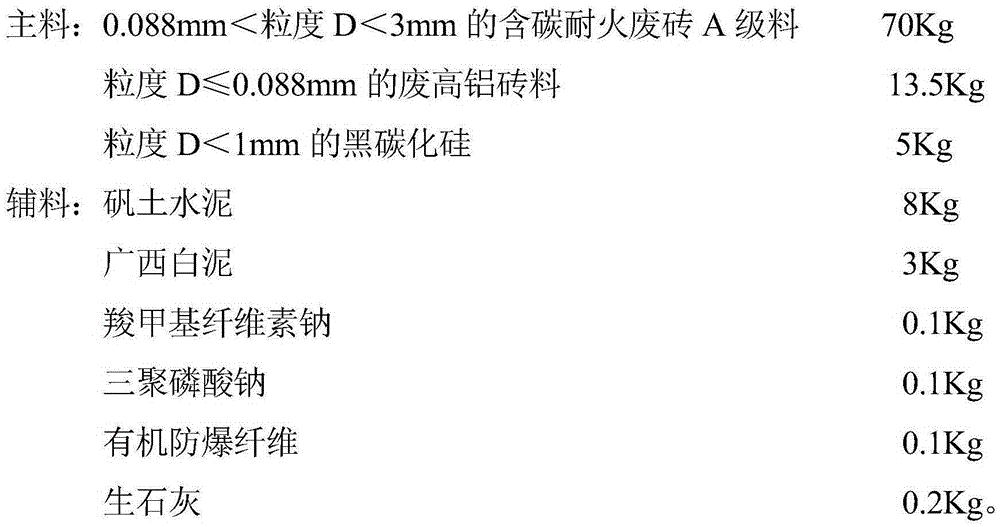

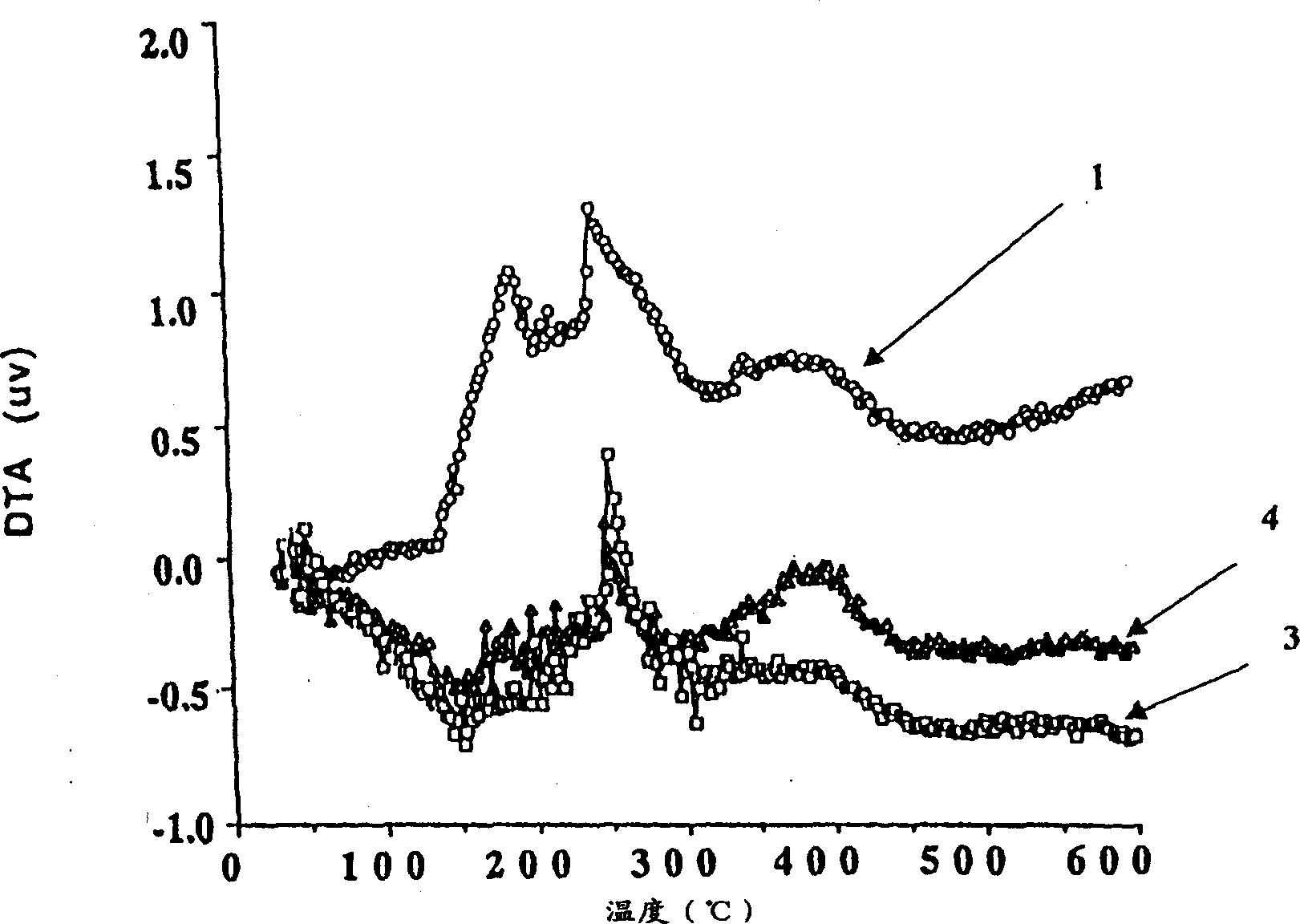

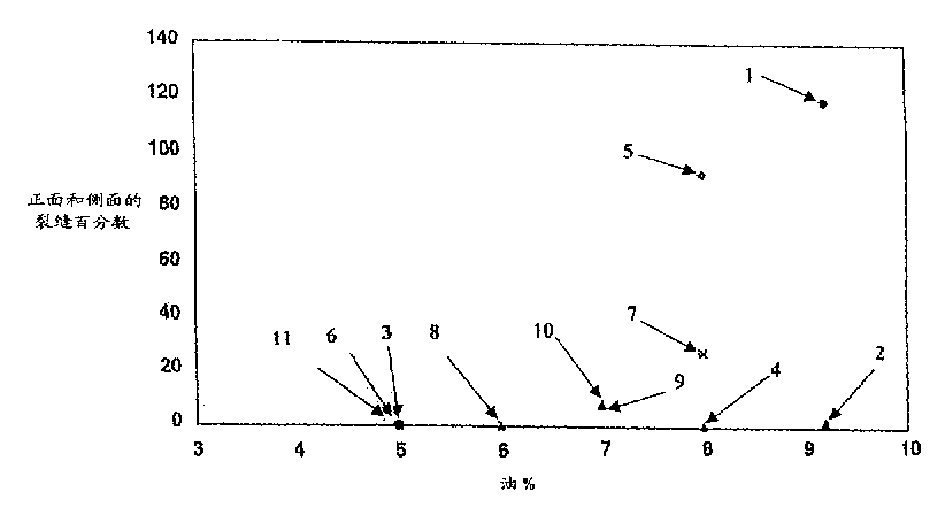

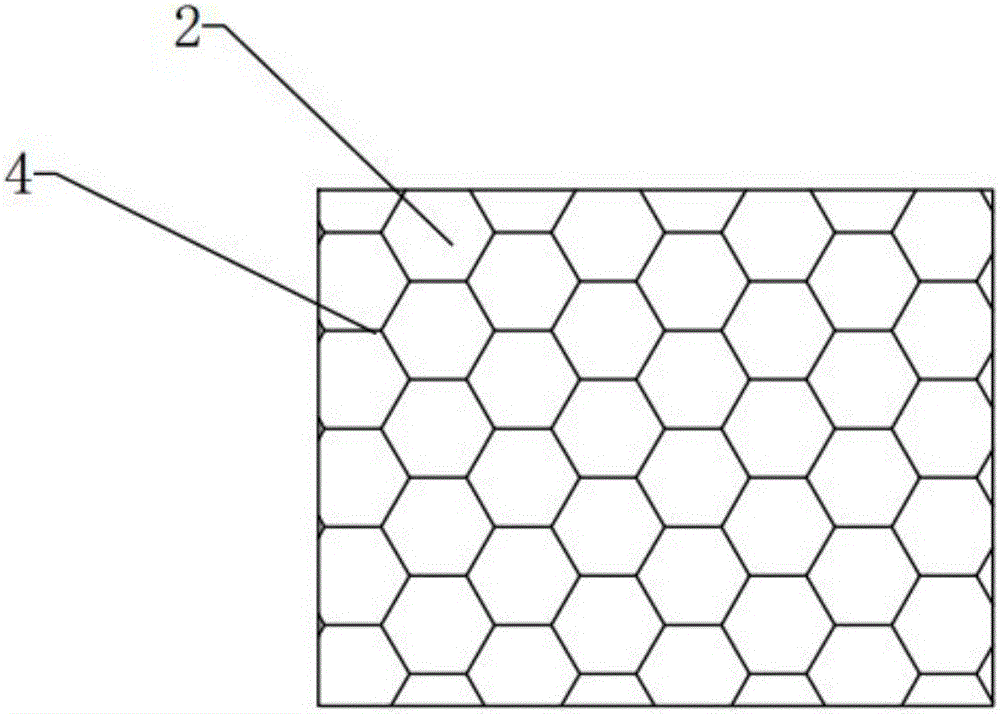

Binder system for honeycomb ceramic bodies and method for producing honeycomb bodies

InactiveCN1304389AReduced firing cracksKeep extrusionCeramic extrusion diesCeramicwareNon solventActive agent

A binder system for use in the formation of ceramic or other powder-formed greenware comprising a binder, a solvent for the binder, a surfactant, and a component that is non-solvent with respect to the binder and solvent. The non-solvent component exhibits a lower viscosity than the solvent when containing the binder and comprises at least a portion of an organic liquid having a 90 % recovered distillation temperature of no greater than about 225 DEG C and more preferably less than 220 DEG C. The invention also discloses a process of forming and shaping plasticized powder mixtures and a process for forming ceramic articles utilizing the binder system.

Owner:CORNING INC

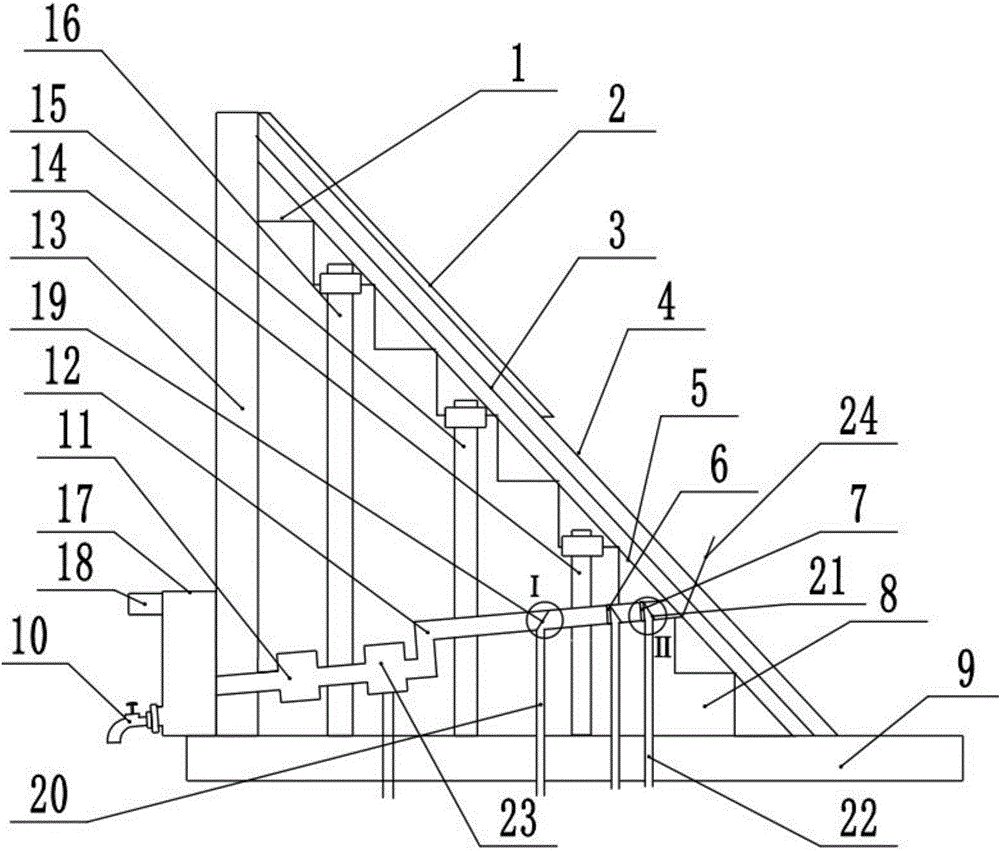

Retaining wall for water conservancy project

The invention relates to a retaining wall, specifically to a retaining wall for a water conservancy project, can prevent humid land from erosion and play the role of preventing collapse and a slump. A water pipe in the retaining wall can lead out river water, and a water source which can be directly used can be obtained by a river water purification filter, so that pedestrians can use water conveniently; and a greening layer is arranged on the retaining wall, thereby playing a role of beautifying a city. A concrete wall is built on the foundation, and a high-strength bolt I, a high-strength bolt II and a high-strength bolt III run through a slope and are arranged in the slope. A prismatic table structure is arranged on the surface of the slope, a plain concrete layer covers on the surface of the prismatic table structure, an anticorrosion layer is arranged on the plain concrete layer, a steel wire slope protection net covers on the surface of the anticorrosion layer, and greening layers are planted in meshes of the steel wire slope protection net. The water pipe is arranged in the slope, one end of the water pipe is provided with a sediment filter screen II and a sediment filter screen I, the other end of the water pipe is provided with a water tank and a faucet, and the river water purification filter is arranged in the middle section of the water pipe.

Owner:TIANJIN UNIV

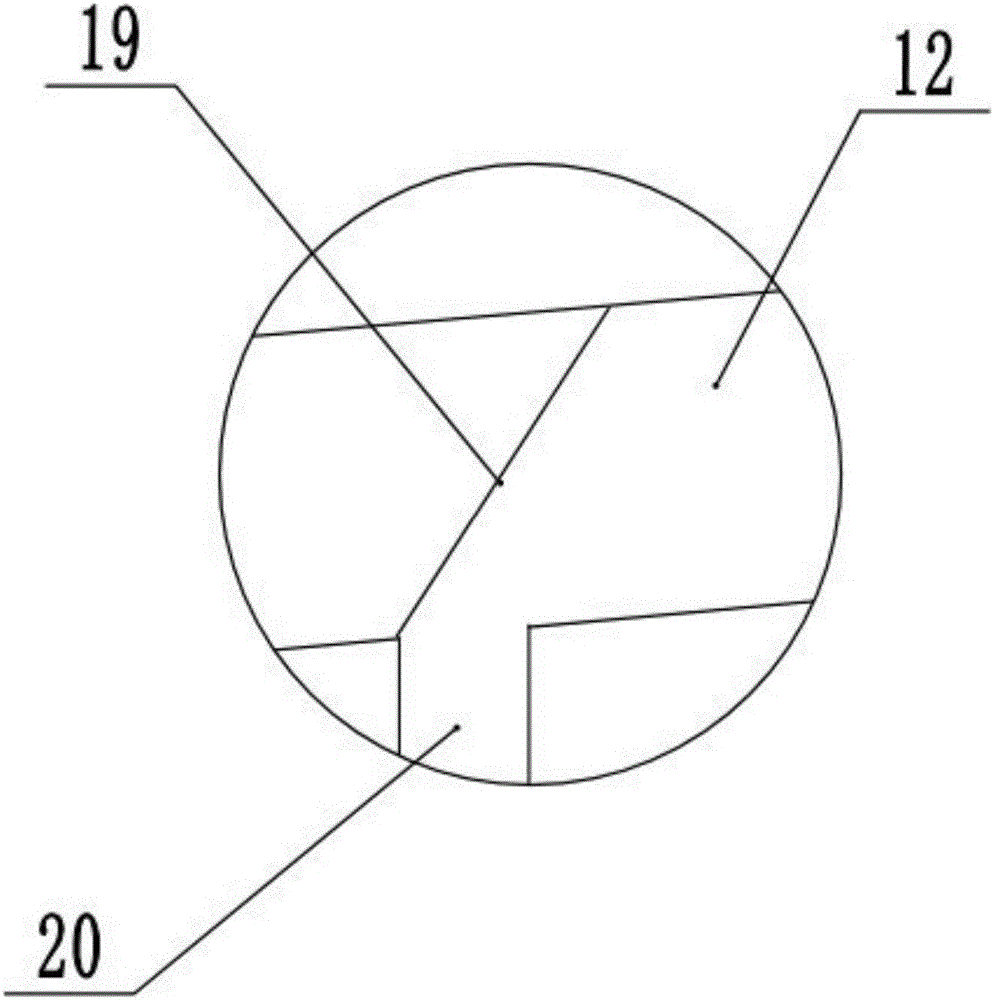

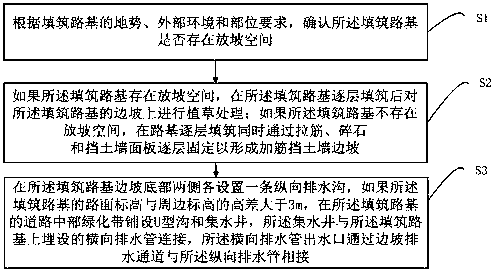

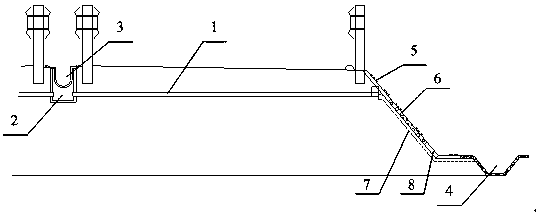

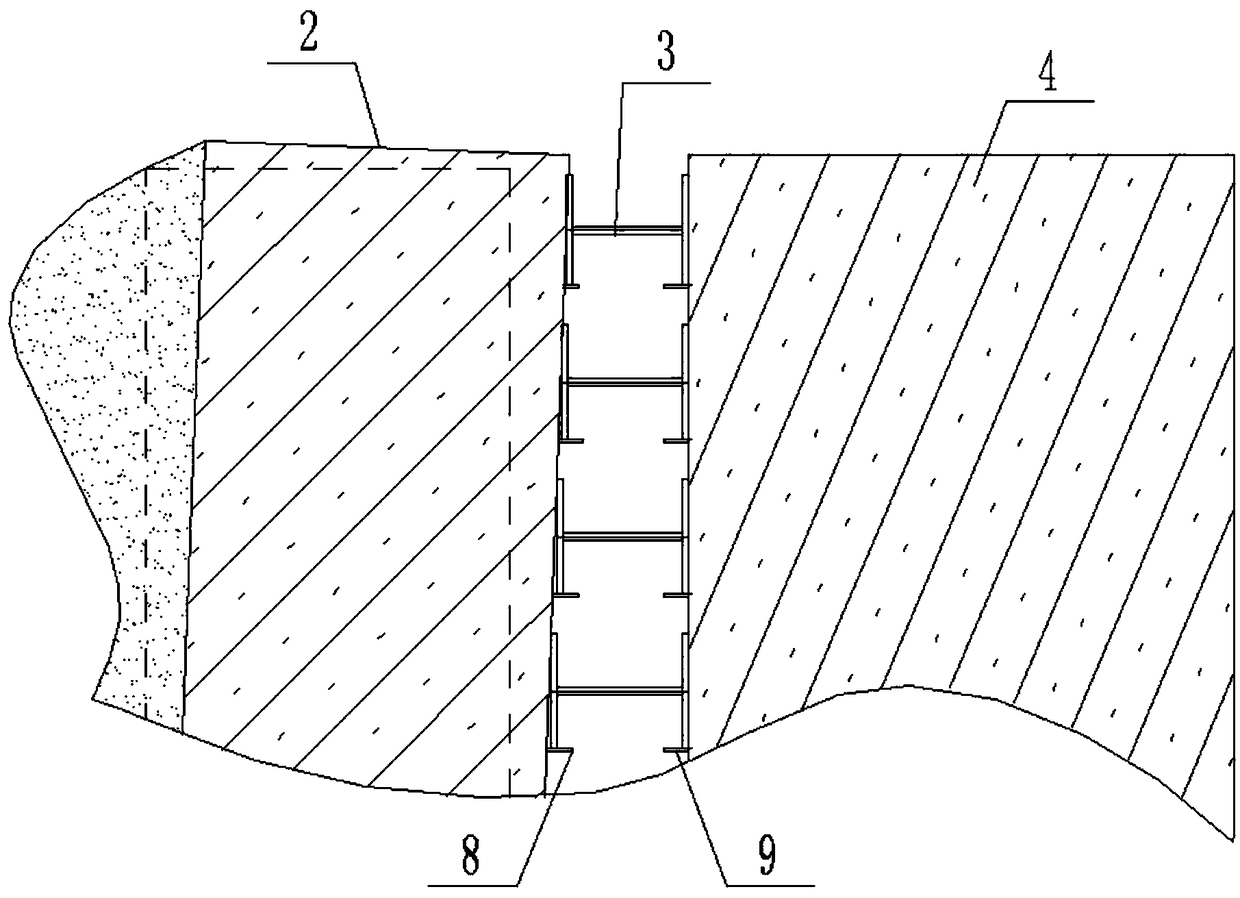

Prevention method for filling roadbed slope stabilization

The invention provides a prevention method for filling roadbed slope stabilization. The prevention method comprises the steps of determining whether a sloping space exists in a filling roadbed or notaccording to requirements on a terrain, an external environment and a part of the filling roadbed; if the sloping space exists in the filling roadbed, planting grass on a slope of the filling roadbedafter filling the filling roadbed layer by layer; and if the sloping space does not exist in the filling roadbed, filling the roadbed layer by layer, and meanwhile, fixing a tie bar, broken stones anda retaining wall panel layer by layer to form a reinforced retaining wall slope. According to the prevention method provided by the invention, different prevention methods are adopted according to the requirements on the terrain, the surrounding environment and the part of the filling roadbed, so that the applicability of filling roadbed slope treatment is improved, the scouring resistance of thefilling roadbed slope is improved, the prevention method is particularly suitable for preventing the hazard of first-class soil filling roadbed sliding, and the stability inside and outside a road embankment is improved.

Owner:CHINA MCC20 GRP CORP

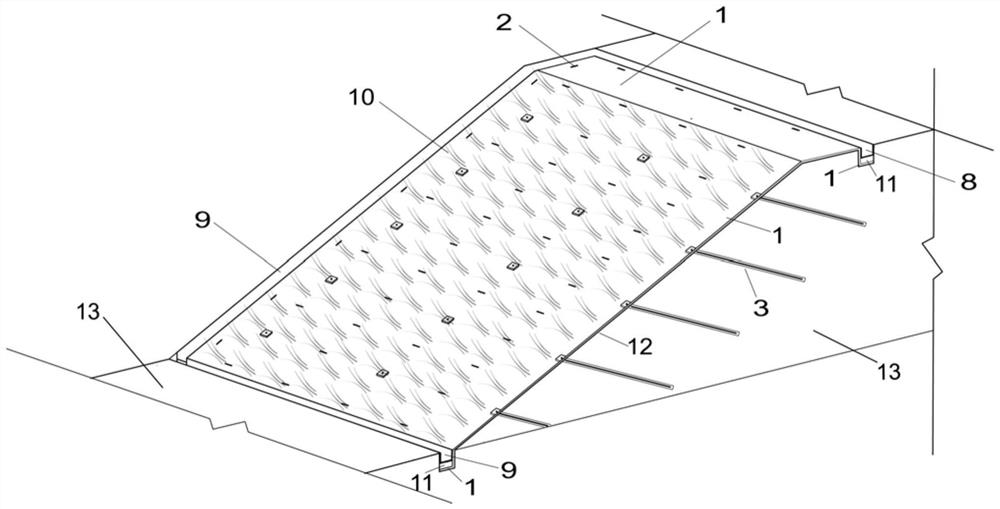

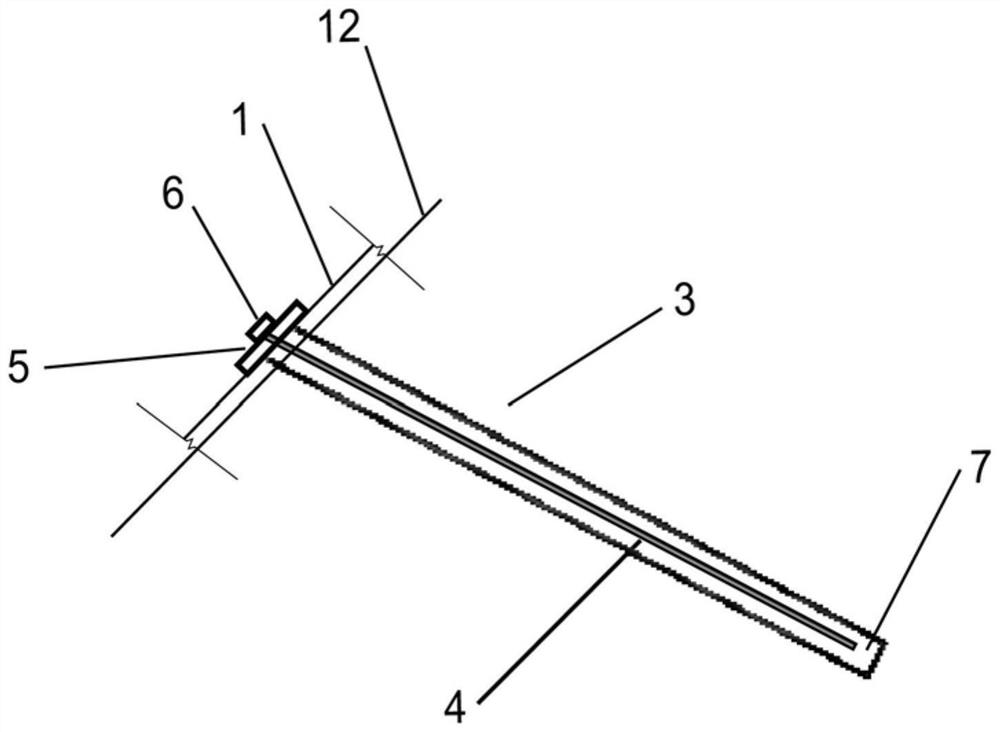

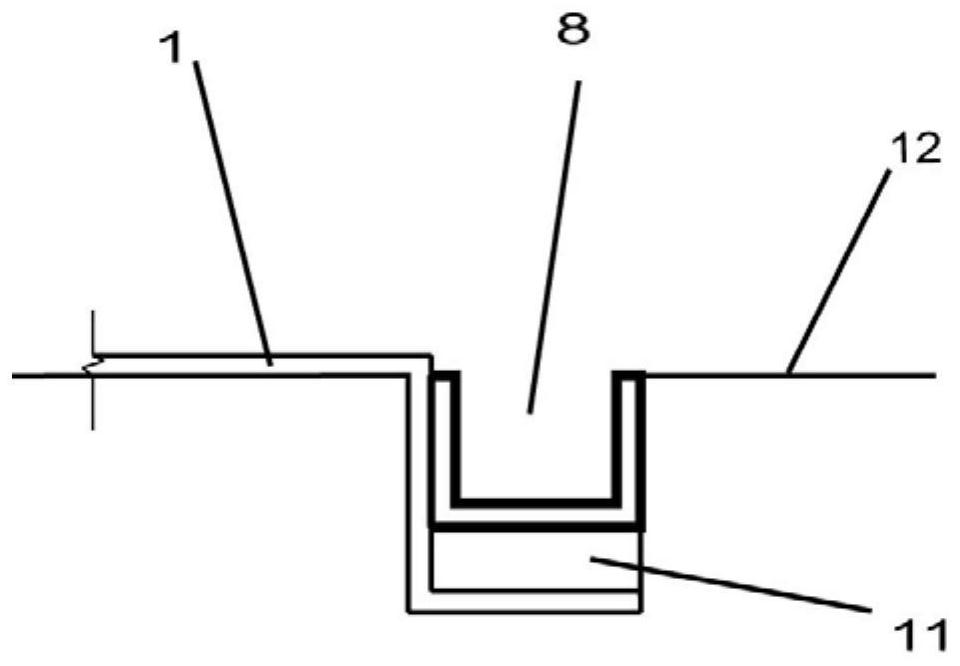

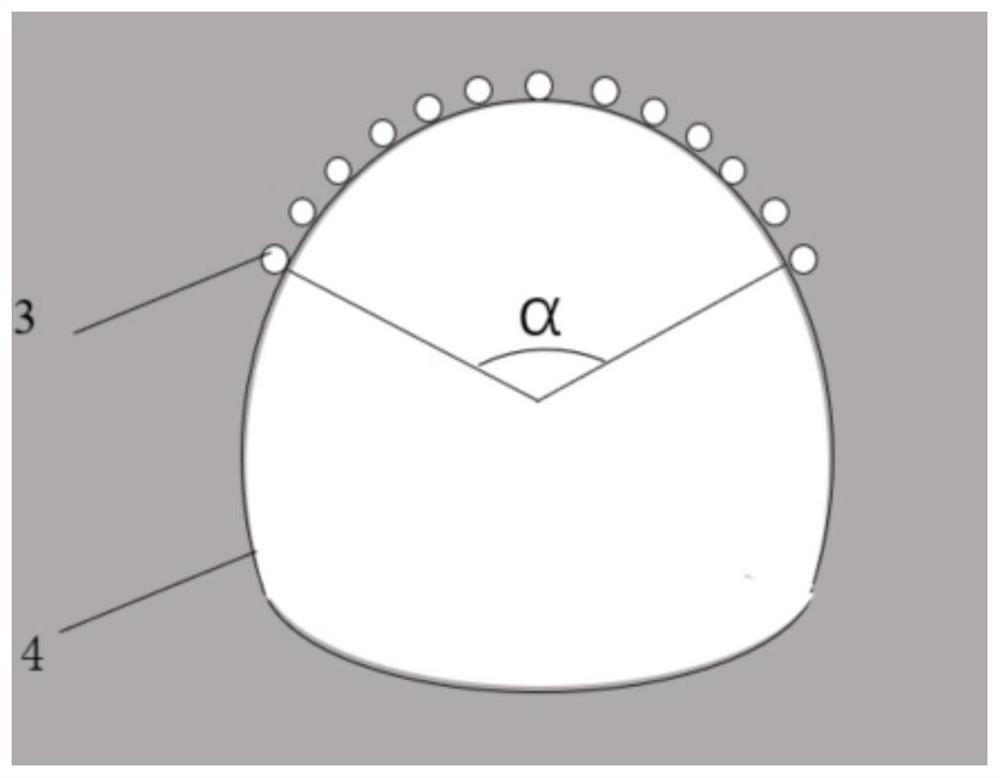

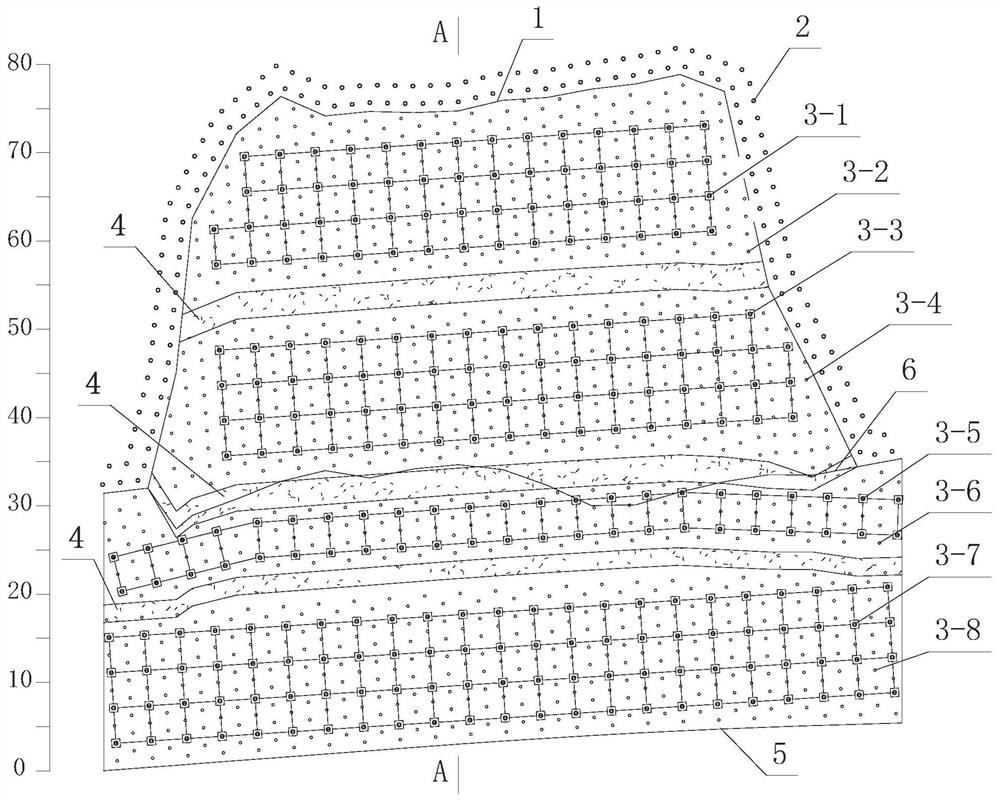

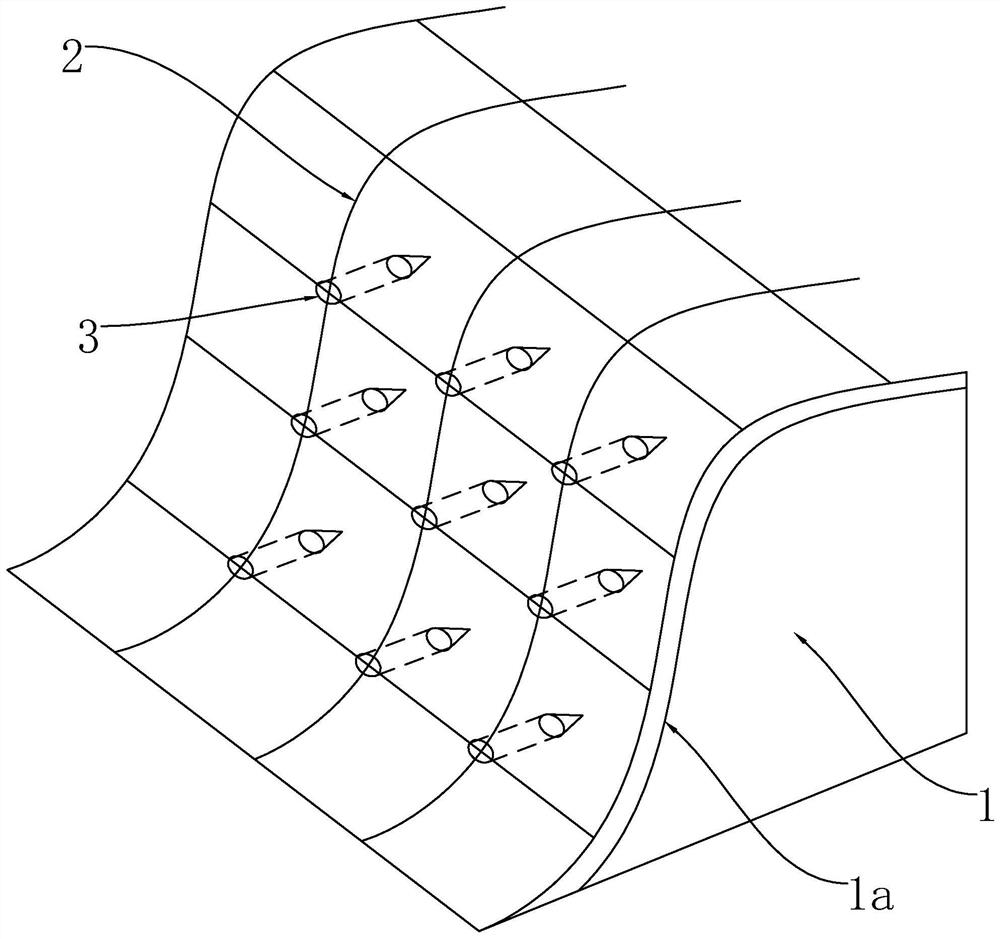

Expansive soil slope flexible ecological supporting structure and construction method

PendingCN114753385AIncrease roughnessReduce shockSewerage structuresExcavationsEnvironmental engineeringDitch

The expansive soil side slope flexible ecological supporting structure comprises a vegetation protection pad, anchor rods, U-shaped nails, a cutting / drainage ditch and slope protection vegetation, the vegetation protection pad is flatly laid on the surface of an expansive soil side slope and is attached to a soil body, and the edge part of the vegetation protection pad is embedded into the bottom of the cutting / drainage ditch; the anchor rods are arranged in the grids of the vegetation protection pad in a rectangular shape; the U-shaped nails are used for fixing the vegetation protection pads between the anchor rods and at the edge of the intercepting / draining ditch; the vegetation protection pad is fixed at the bottom of the interception / drainage ditch, the interception / drainage ditch is manufactured at the upper part according to the designed depth, and the interception / drainage ditch is finally merged into a drainage system and is arranged at the side slope protection outer edge; the slope protection vegetation is densely planted in the three-dimensional grid space of the vegetation protection pad. Surface layer protection of the slow expansive soil side slope can be achieved, the overall stability of the side slope is improved, and the long-term treatment effect is good.

Owner:GUANGXI UNIV

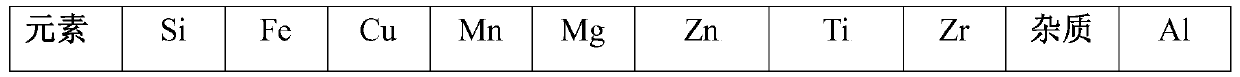

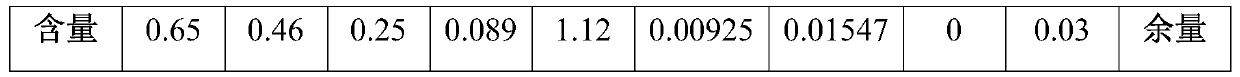

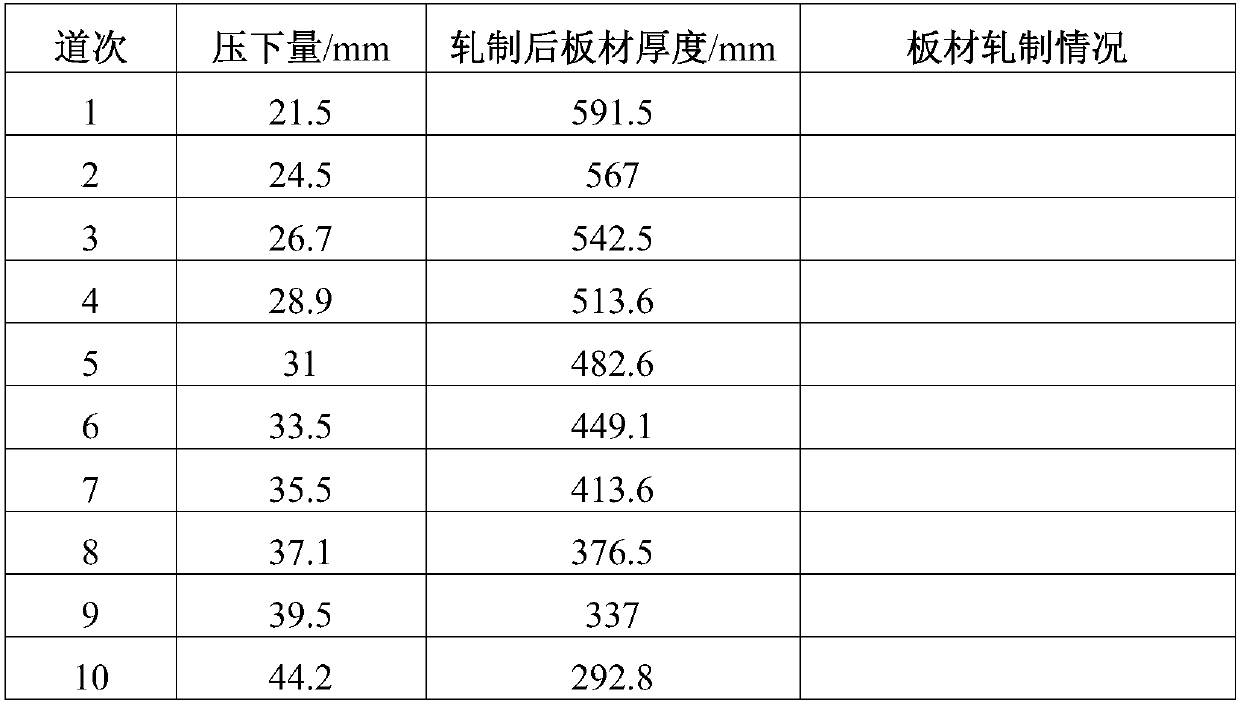

Machining technology of ultrawide 6061 aluminum alloy panel for military test detection platform

The invention belongs to the technical field of aluminum alloy, and relates to a machining technology of an ultrawide 6061 aluminum alloy panel for a military test detection platform. Aluminum alloy is prepared from, by weight percentage, 0.63-0.69% of Si, 0.45-0.55% of Fe, 0.2-0.3% of Cu, 0.08-0.12% of Mn, 1.05-1.15% of Mg, 0-0.1% of Zn, 0.013-0.02% of Ti, 0-0.05% of Zr, 0-0.05% of single impurities, and the balance Al, wherein the total weight percentage of the above raw materials except Al is smaller than or equal to 0.15%. The lost pass is added in the hot rolling process, during shallow pass, by cooling the panel with rolling mill air-blowing equipment, the purpose of uniformly and slowly lowering the finish rolling temperature is achieved, arching of the back of the panel due to theexcessive width is avoided, and the problems that for the ultrawide 6061 aluminum alloy panel prepared through an existing machining technology, the contradiction between the width and flatness of thepanel and the machining deformation is prominent, and it is hard to meet customer needs are solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

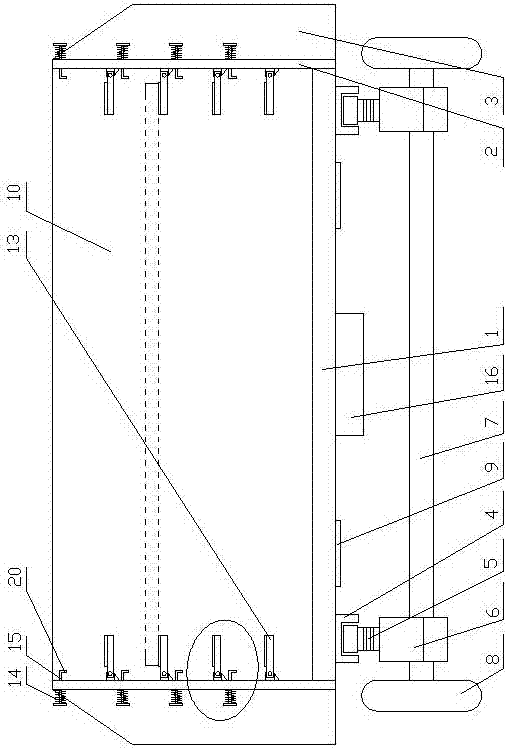

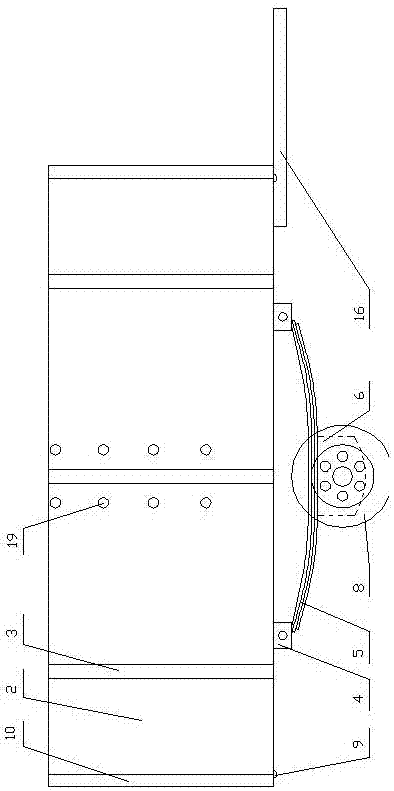

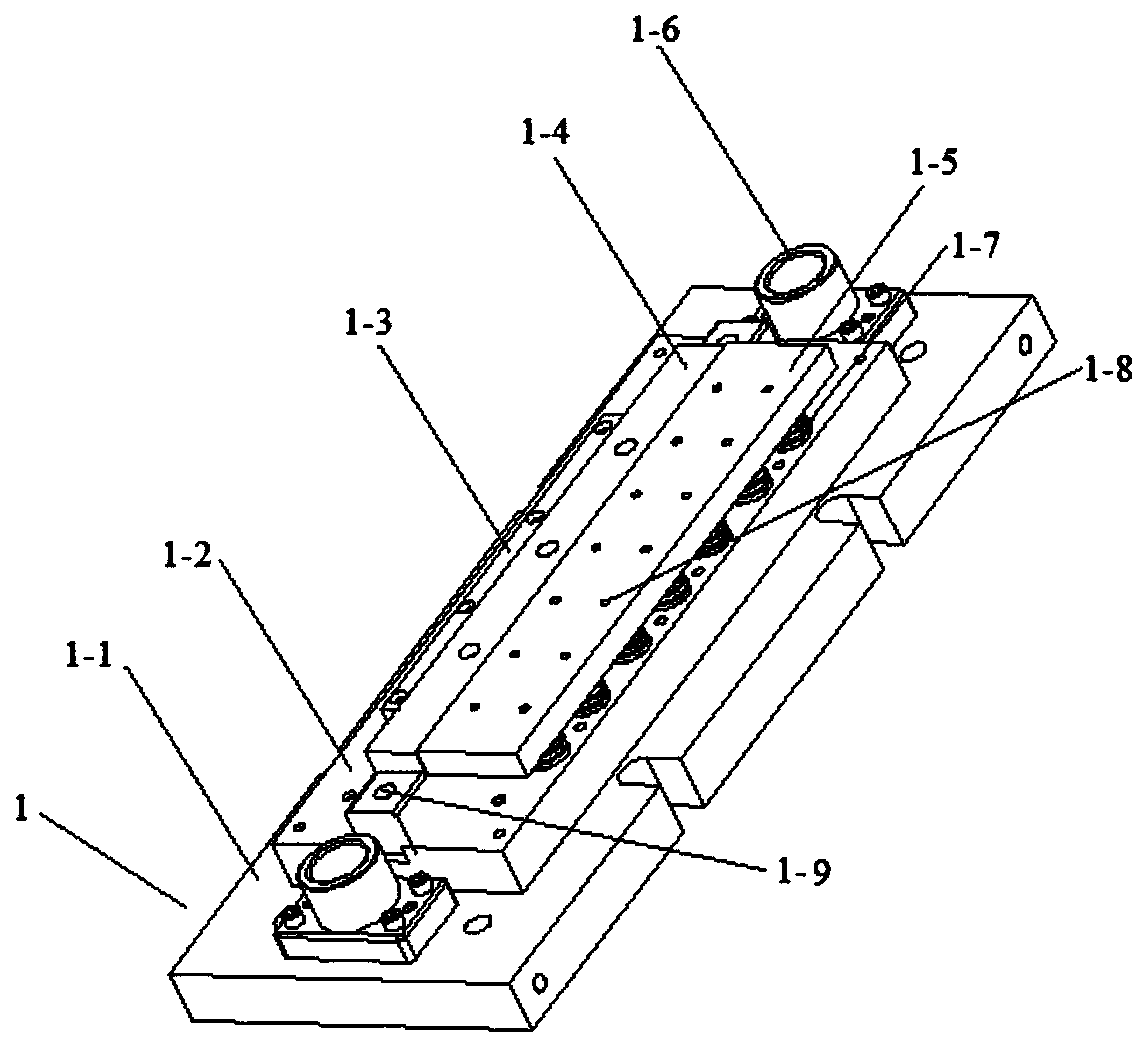

Special transporting device for machining plates

InactiveCN107415804APrevent slumpHigh strengthTractor-trailer combinationsLoad securingEngineeringTorsion spring

The invention discloses a special transporting device for machining plates. The special transporting device for the machining plates comprises a vehicle bottom plate; side plates are welded on both sides of the vehicle bottom plate; a group of reinforcing ribs are welded outside the side plates; one group of bow slice seats are welded at the bottom of the vehicle bottom plate; the bow slice seats are matched with one group of bow slices; the bow slices are connected with wheel axle seats; the wheel axle seats are in running fit with a wheel axle; wheels are mounted at two ends of the wheel axle; two ends of the vehicle bottom plate are hinged with a stopping door through one group of hinges; one group of torsion spring shaft seats are welded on the inner walls of the side plates; the torsion spring shaft seats are hinged with supporting plates through torsion spring shafts; one group of locating rods also penetrate through the side plates; the locating rods are matched with the side plates through thrust springs; and the locating rods are adaptive to the supporting plates. The special transporting device for the machining plates is used for transporting the plates, can prevent scratches on the surfaces of the plates due to the frictions between the plates and can also reduce the impact of bumping on the plates during running by using shock absorbing rubber blocks to match the shock absorbing bow slices.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Treatment method suitable for roadbed slope body collapse

ActiveCN109208619AMeet the needs of emergency managementAvoid leaningExcavationsReceptacle cultivationLand acquisitionMedicine

The present invention relates to the field of side slope or slope stabilization treatment, and discloses a treatment method suitable for roadbed slope body collapse. The method comprises the followingsteps of: S1, stepped downloading; S2, grouting of steel flower tubes; S3, addition of a reinforced slide-resistant pile; S4, surface and underground intercepting drainage; and S5, slope treatment. The treatment method suitable for roadbed slope body collapse is suitable for reinforcing treatment in a later remediation mode for the roadbed slope body which generates slippage deformation and an inclined slide-resistant pile so as to effectively avoid further deformation treatment of the high and steep road roadbed slope body, is obvious in treatment effect, does not need extra land acquisition, is less in occupation of land, reduces land acquisition cost and related removal expense and is low in treatment cost.

Owner:中铁长江交通设计集团有限公司

Drainage ditch compound section wrapping type grass mat slope protection method for coastal reclamation areas

InactiveCN102817338AReduce washoutImprove structural performanceSoil drainageCoastlines protectionSoil scienceLandslide

The invention discloses a drainage ditch compound section wrapping type grass mat slope protection method for coastal reclamation areas. The method is performed according to the following steps: (1) constructing a drainage ditch compound section, wherein the drainage ditch compound section comprises a groove, groove side slopes, a bottomland, swale side slopes, slope tops and ridge side slopes; (2) using a grass mat to perform integrated wrapping coverage on the swale side slopes, the slope tops and the ridge side slopes and perform the integrated wrapping coverage on the groove side slopes and the bottomland by being vertical to the central line of the groove; and (3) nailing wood piles at the overlapped parts and the corners of the grass mat, arranging the wood piles in rows and columns at intervals of 1.5-2m and then binding iron wires on the wood piles in a diagonal crossing form. According to the drainage ditch compound section wrapping type grass mat slope protection method disclosed by the invention, the integral structure and the stability of the side slopes are improved, the erosion of the side slopes can be effectively reduced, and the occurrence of soil collapse and landslide phenomena can be prevented.

Owner:HOHAI UNIV

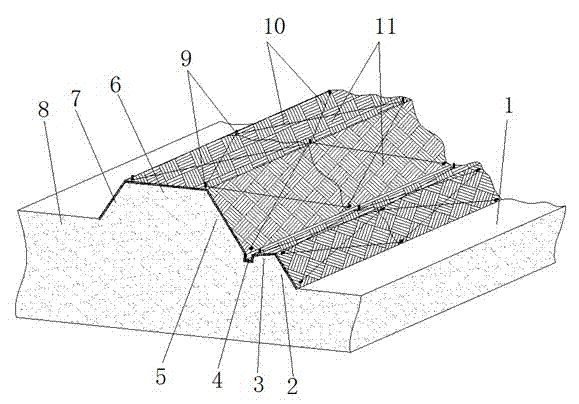

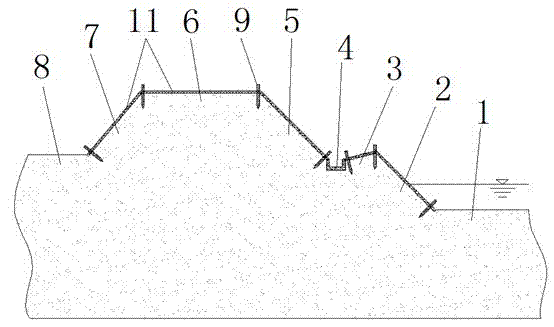

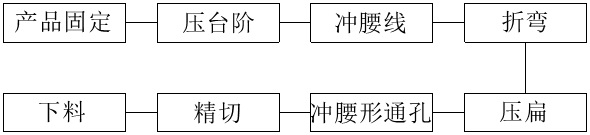

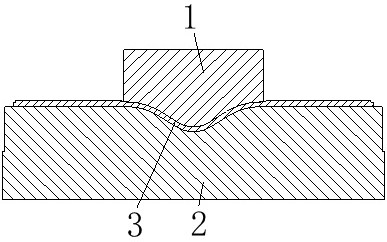

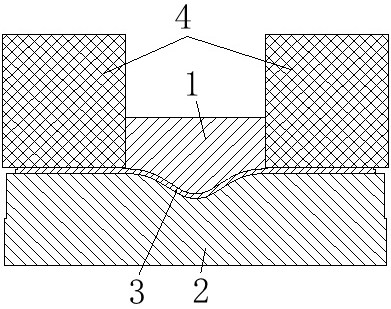

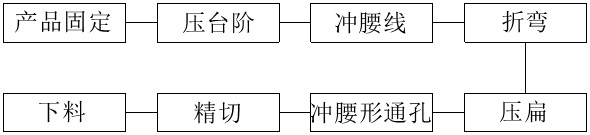

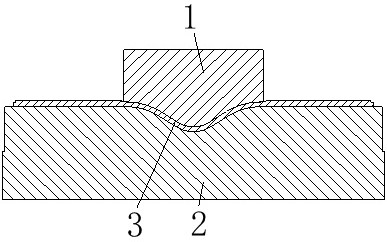

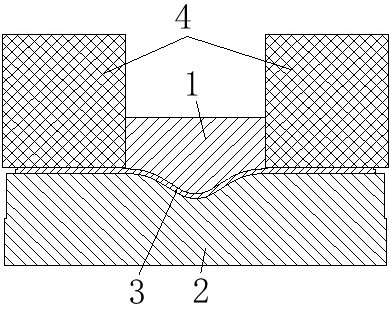

High-pressure copper bar processing technique capable of overcoming punching corner collapse

ActiveCN111804772APrevent slumpGuarantee that the bending degree meets the requirementsPunchingStructural engineering

The invention provides a high-pressure copper bar processing technique capable of overcoming punching corner collapse, comprising the following steps: product fixation: fixing a high-pressure copper bar on a lower mold; bending: bending the high-pressure copper bar from the middle portion by pressing an upper mold and the lower mold; flattening: flattening straight portions of both ends of the bent high-pressure copper bar by using an upper mold flattening punch; precise cutting: precisely cutting the straight portions of both ends of the flattened high-pressure copper bar by using a precise cutting punch; and product falling: taking out the high-pressure copper bar from the lower mold after precise cutting and burr removal. The high-pressure copper bar processing technique capable of overcoming punching corner collapse provided by the invention performs the precise cutting process after flattening and thinning the high-pressure copper bar, and vertically cuts off the part extending outwards by precise cutting to effectively prevent the corner collapse problem of the high-pressure copper bar; and finally, during glue injection, the glue leakage is prevented, and the contact area ofthe high-pressure copper bar is fully guaranteed, so that the electric performance of the high-pressure copper bar after glue injection is guaranteed.

Owner:宁波峰梅精密科技有限公司

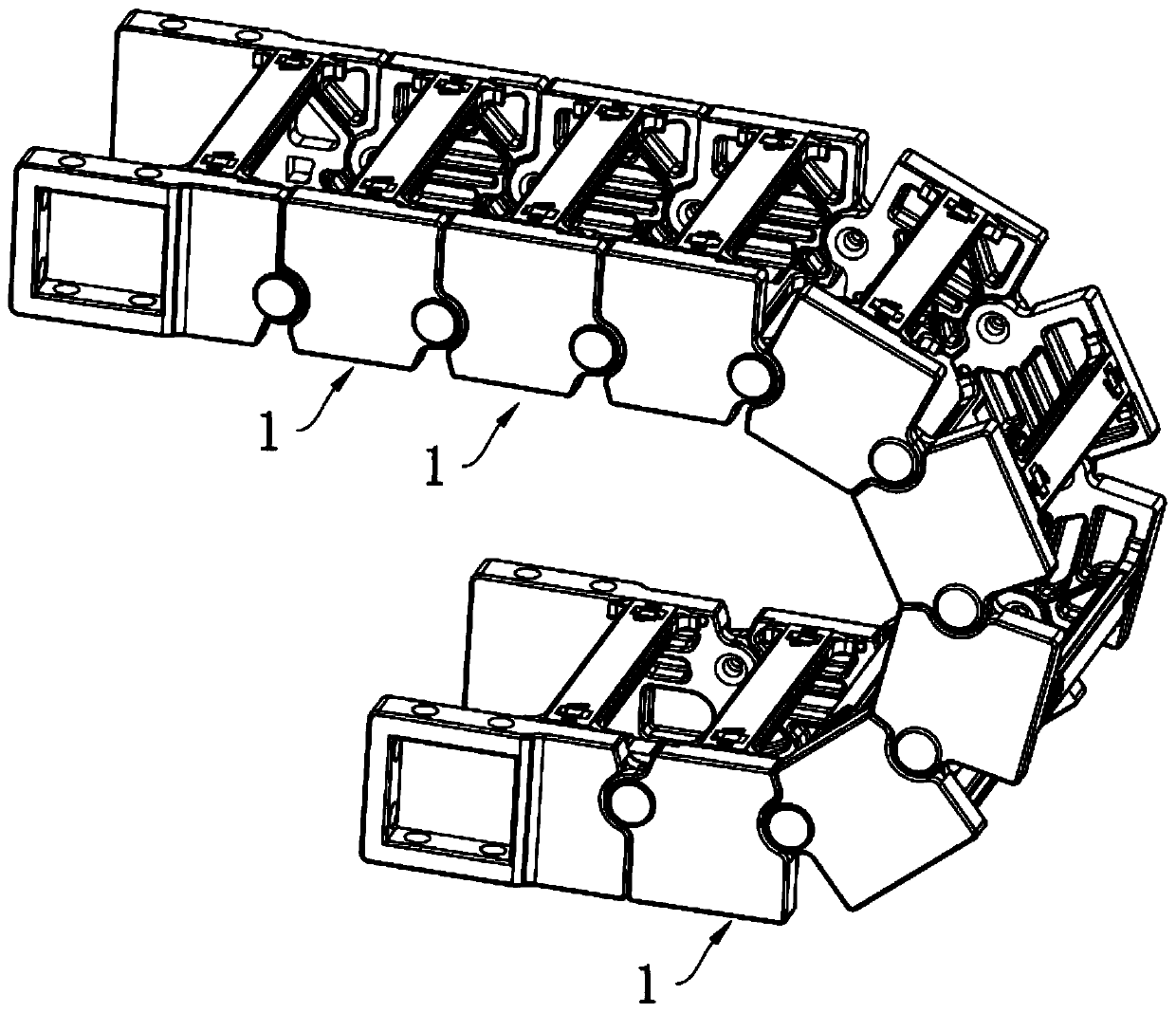

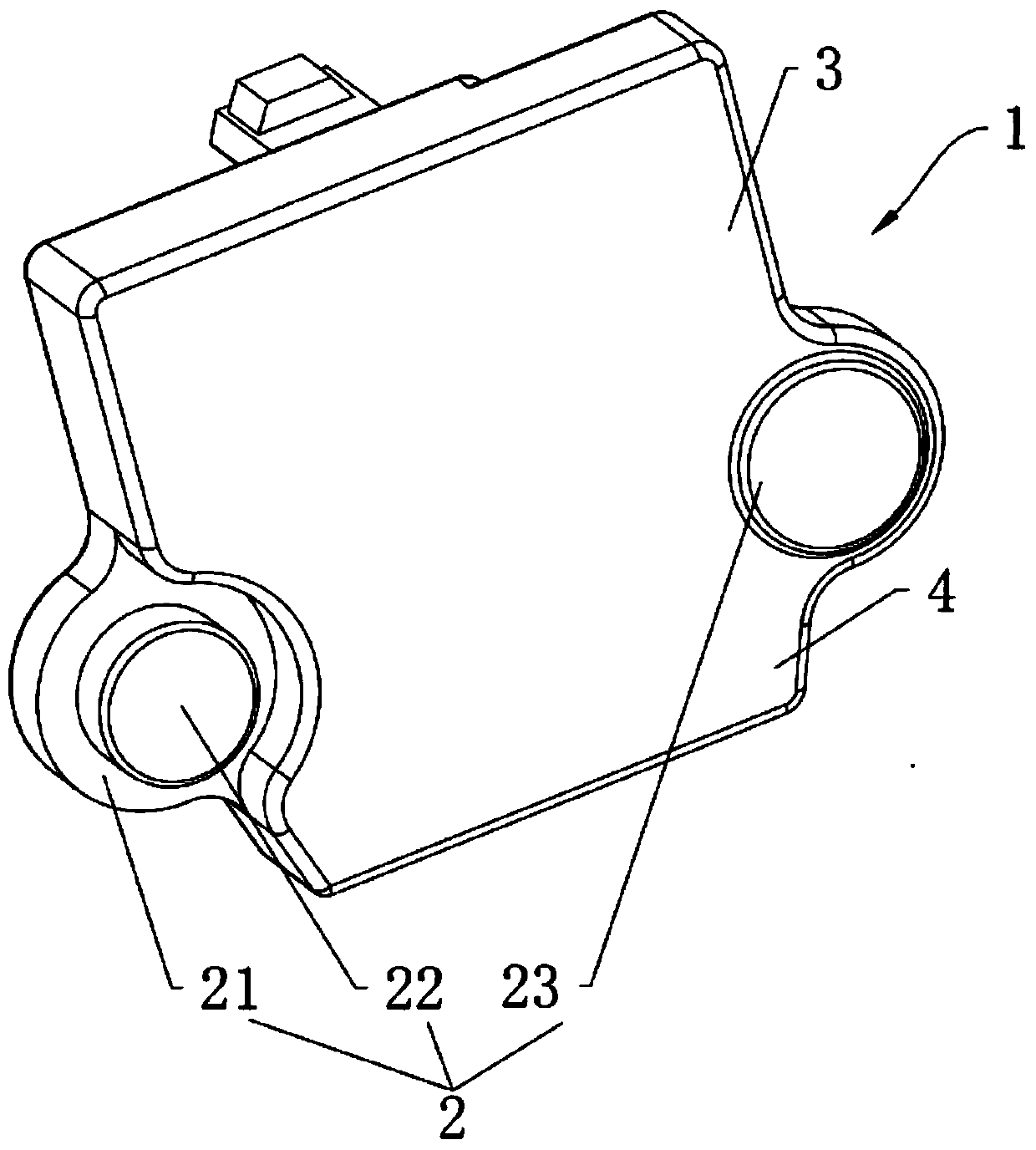

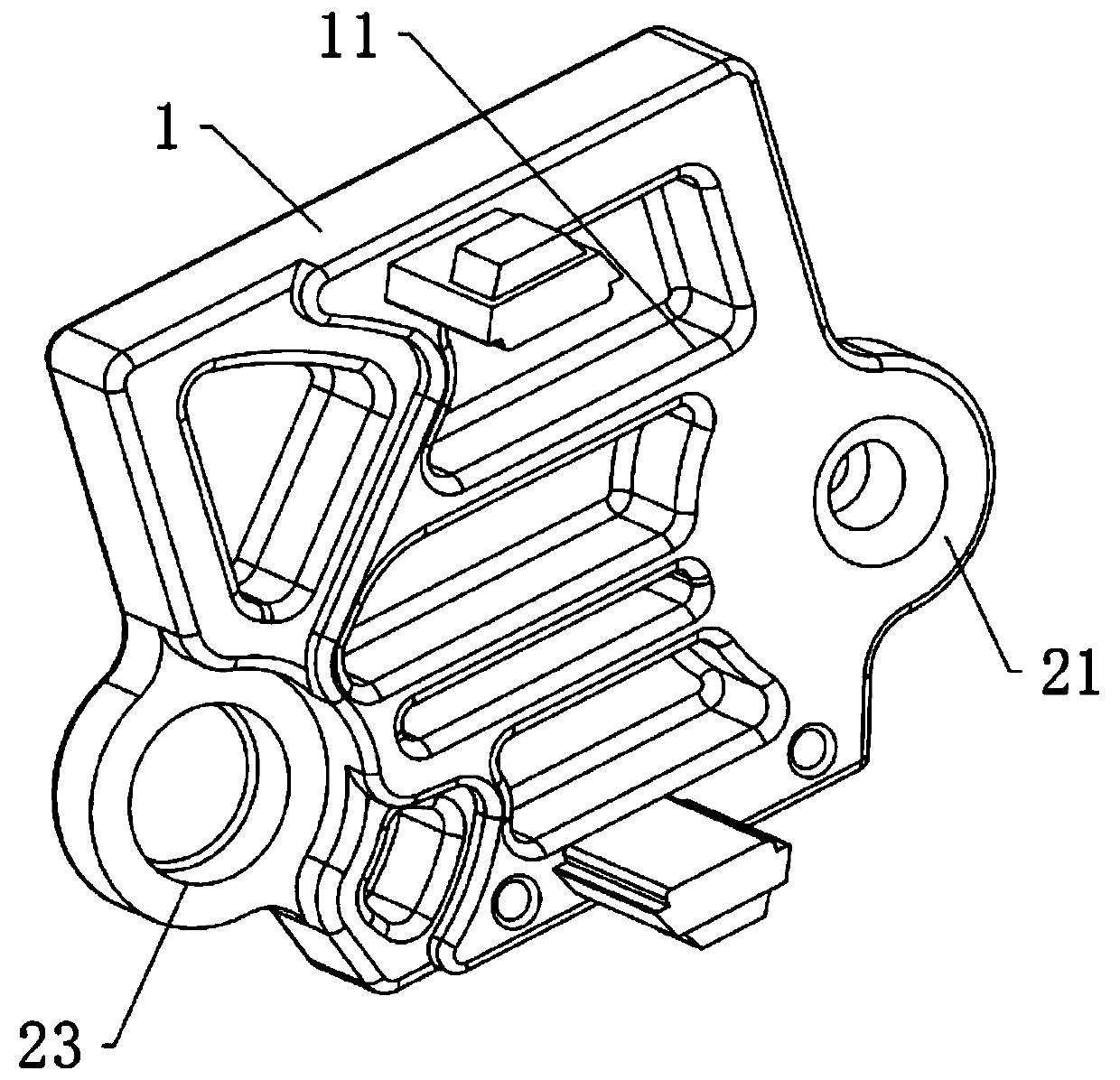

Drag chain

PendingCN111188873APrevent slumpExtended service lifeHauling chainsHoisting chainsPull forceEngineering

The invention belongs to the technical field of drag chain equipment and discloses a drag chain. The drag chain comprises a plurality of main body chain plates and pin shaft parts; the main body chainplates are sequentially hinged end to end in a limitation manner by virtue of the pin shaft parts; the main body chain plates are divided into upper chain plates and lower chain plates by the linkedline of the axes of the plurality of pin shaft parts; the end face of one side of each upper chain plate is matched with the end face of the other side of the corresponding upper chain plate; the endface of one side of each lower chain plate is matched with the end face of the other side of the corresponding lower chain plate; the plurality of main chain plates are supported by virtue of lever supporting of the pin shaft parts so that the lower chain plates are connected in a leaning manner and the upper chain plates are opened to transform the load force born by the drag chain into longitudinal tensile force of the lower chain plates and the longitudinal jacking force of the upper chain plates, thereby increasing the strength and the bearing capacity of the drag chain and effectively preventing deformation and waist collapse of the drag chain.

Owner:深圳市华南天城机床配件有限公司

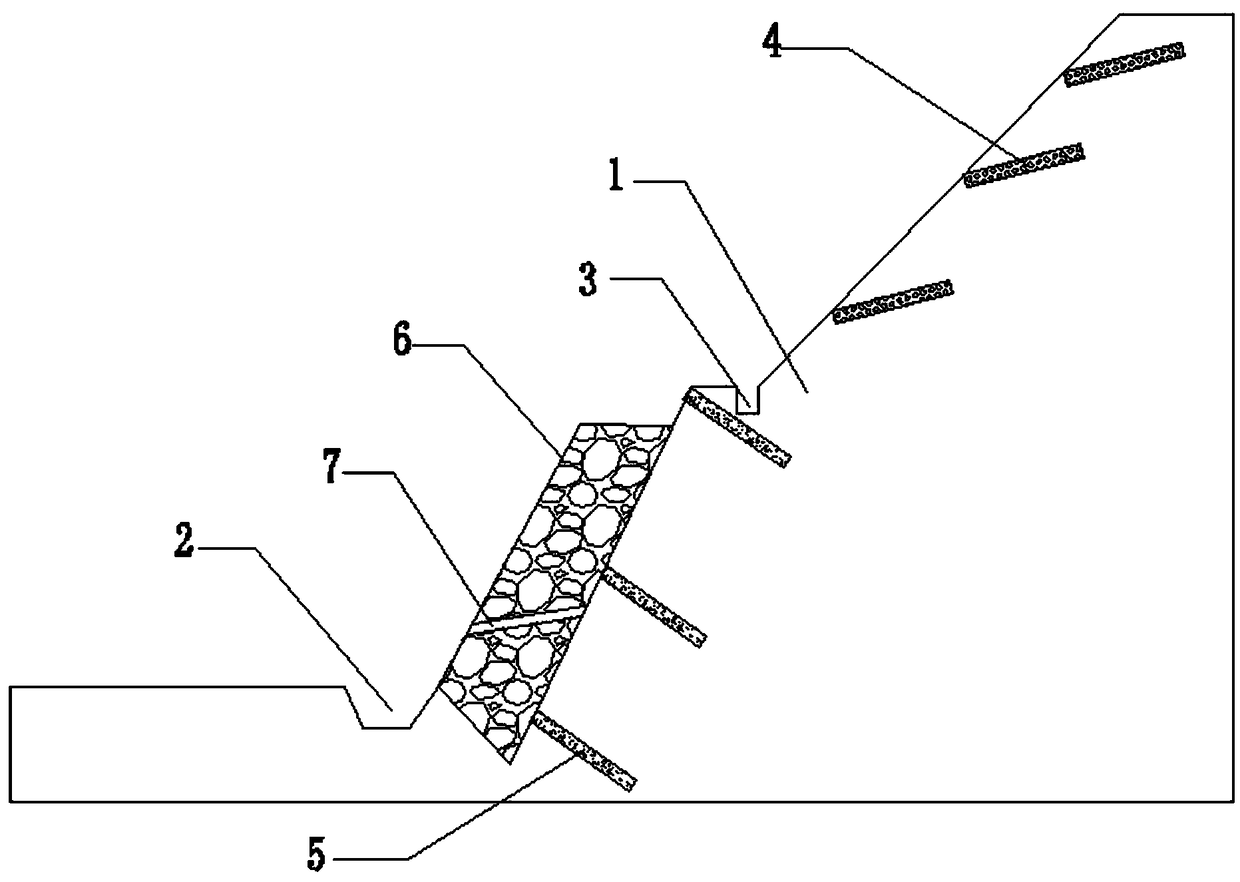

High seepage slope reinforcement diversion and drainage system and construction method

The invention provides a high seepage slope reinforcement diversion and drainage system and a construction method. The construction method comprises the steps that an easy-to-collapse excavation slopeto be reinforced is leveled; then slurry spraying piles at the lower part of a high slope is constructed; when the strength of the slurry spraying piles reaches 85% of the design strength, granular material piles on an upper slope are constructed; and finally a retaining wall and a slope protection project are constructed to form combined support and connect a water outlet to form an integrated drainage system with a roadbed drainage project. The lower slope surface is reinforced by the slurry spraying piles to form a relatively dense soil body with certain strength, and the outer part is further supported by the inclined retaining wall; water flow on the slope surface flows through the granular material piles of the upper soil body, and the granular material piles have the function of compacting the soil body, have certain strength and can be used as a drainage channel at the same time; and granular materials can act as a filter layer to drain water and protect soil, so that the possible water flow is discharged out of the soil body of the slope, and a series of diseases such as collapse, slump and landslide of the high slope are prevented.

Owner:CHINA MCC17 GRP

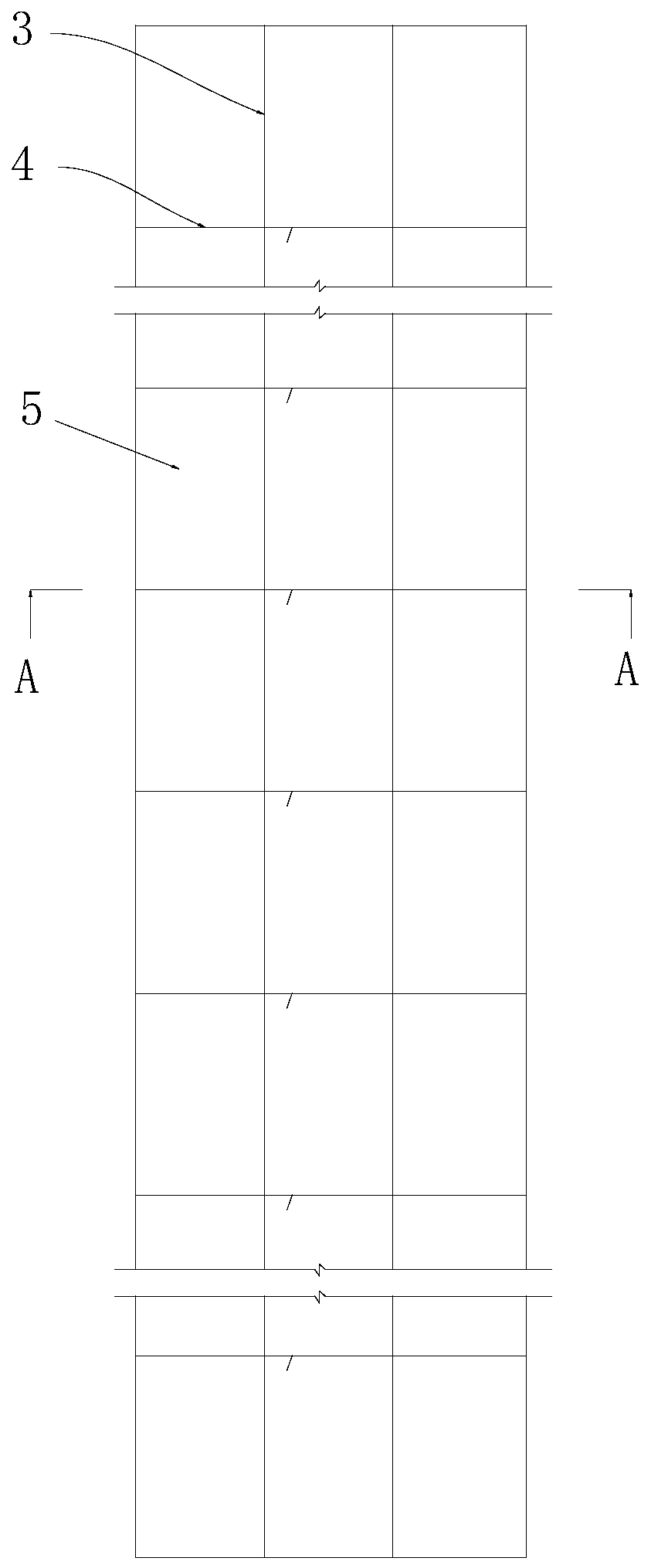

Tunnel construction and maintenance integrated freezing damage-water damage prevention and control method

PendingCN113700490ALow costImprove rock structureUnderground chambersSeismologyTunnel engineeringTunnel construction

The invention discloses a tunnel construction and maintenance integrated freezing damage-water damage prevention and control method, and belongs to the technical field of tunnel engineering construction. The specific scheme comprises the following steps that 1, the geological condition of soft rock and the development condition of underground water are detected accurately by using an advanced hole detection technology; 2, advanced drilling drainage and pressure reduction are carried out on a water-rich section according to an advanced hole detection result; 3, grouting and water plugging are conducted on an advanced small guide pipe, and surrounding rock is reinforced; 4, a primary support structure is excavated and constructed; 5, after primary support construction is completed, radial small guide pipes are constructed; 6, an inverted arch is excavated, and inverted arch concrete is poured; and 7, a secondary lining is constructed. According to the tunnel construction and maintenance integrated freezing damage-water damage prevention and control method, the influence of underground water and soft rock lithology on construction of the high-water-rich soft rock mountain ridge tunnel in an extreme freeze-thaw area is avoided, harm and damage to a tunnel in the high-water-rich freeze-thaw environment are effectively controlled, and the influence of freeze-thaw factors on tunnel construction and the operation period is reduced.

Owner:HARBIN INST OF TECH

A high-voltage copper bar processing technology to overcome stamping slump

ActiveCN111804772BPrevent slumpGuarantee that the bending degree meets the requirementsPunchingElectrical performance

Owner:宁波峰梅精密科技有限公司

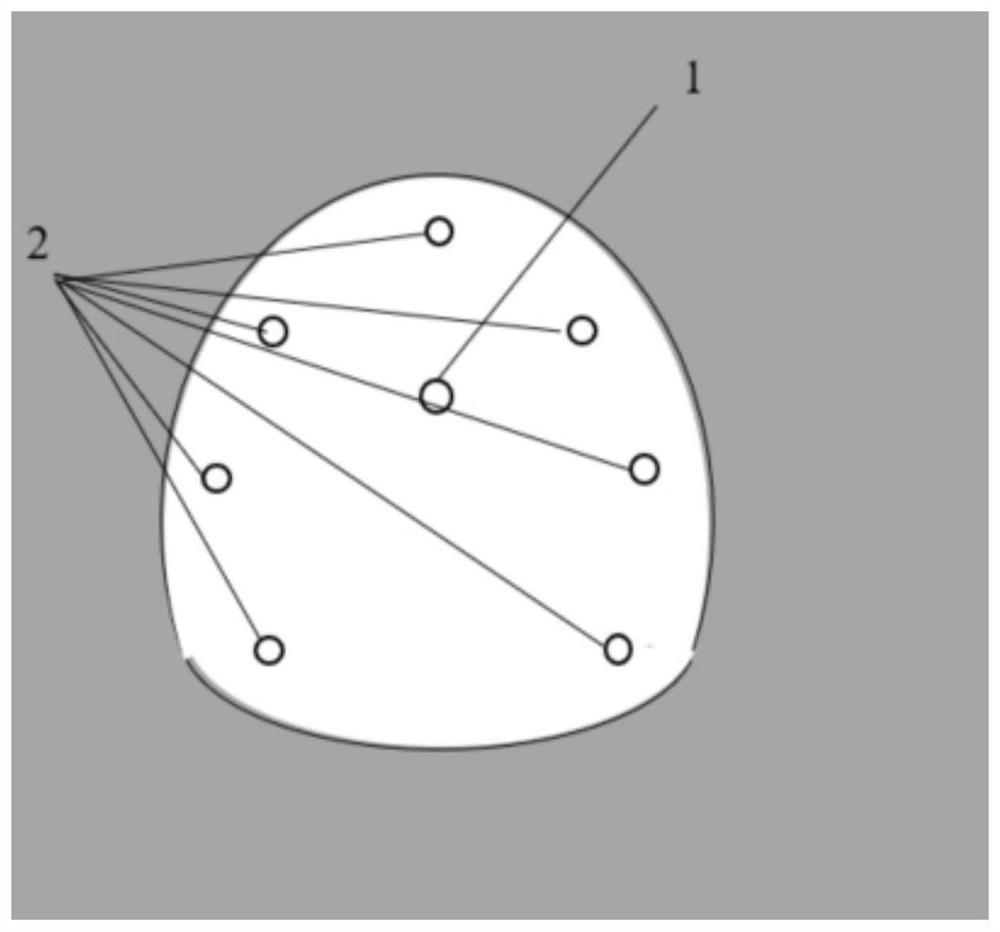

Treatment method for sliding of high slope of fragmented bulk solid on surface layer of deep-layer strong-dumping deformation body

The invention discloses a treatment method for sliding of a high slope of fragmented bulk solid on the surface layer of a deep-layer strong-dumping deformation body, and relates to the field of slopeengineering. The technical problem to be solved is to provide a high-safety-risk and short-construction-cycle treatment method for sliding of the high slope. By means of the technical scheme, the treatment method for sliding of the high slope of the fragmented bulk solid on the surface layer of the deep-layer strong-dumping deformation body includes the steps of firstly, performing quick slag filling and reversely pressing the foot of the slope, restraining excessive deformation of the slope, and preventing deep-layer landslide; then, setting slope deformation temporary monitoring points, andconstructing a slope construction road; restraining loose deformation of the top of the slope through fore shaft anchor rods; cutting the slope and reducing the load to eliminate the source of dangeron the top of the slope; and finally, supporting the slope, wherein grouting is performed on broken rock mass on the surface layer of the slope through slope surface anchor rods according to the characteristic that the dumping deformation broken rock soil can be injected so that the loose broken rock can coagulate to have a bearing capacity. The method is suitable for sliding of the slope with thestrong-dumping deformation body on the deep layer and the fragmented bulk solid on the surface layer.

Owner:POWERCHINA CHENGDU ENG

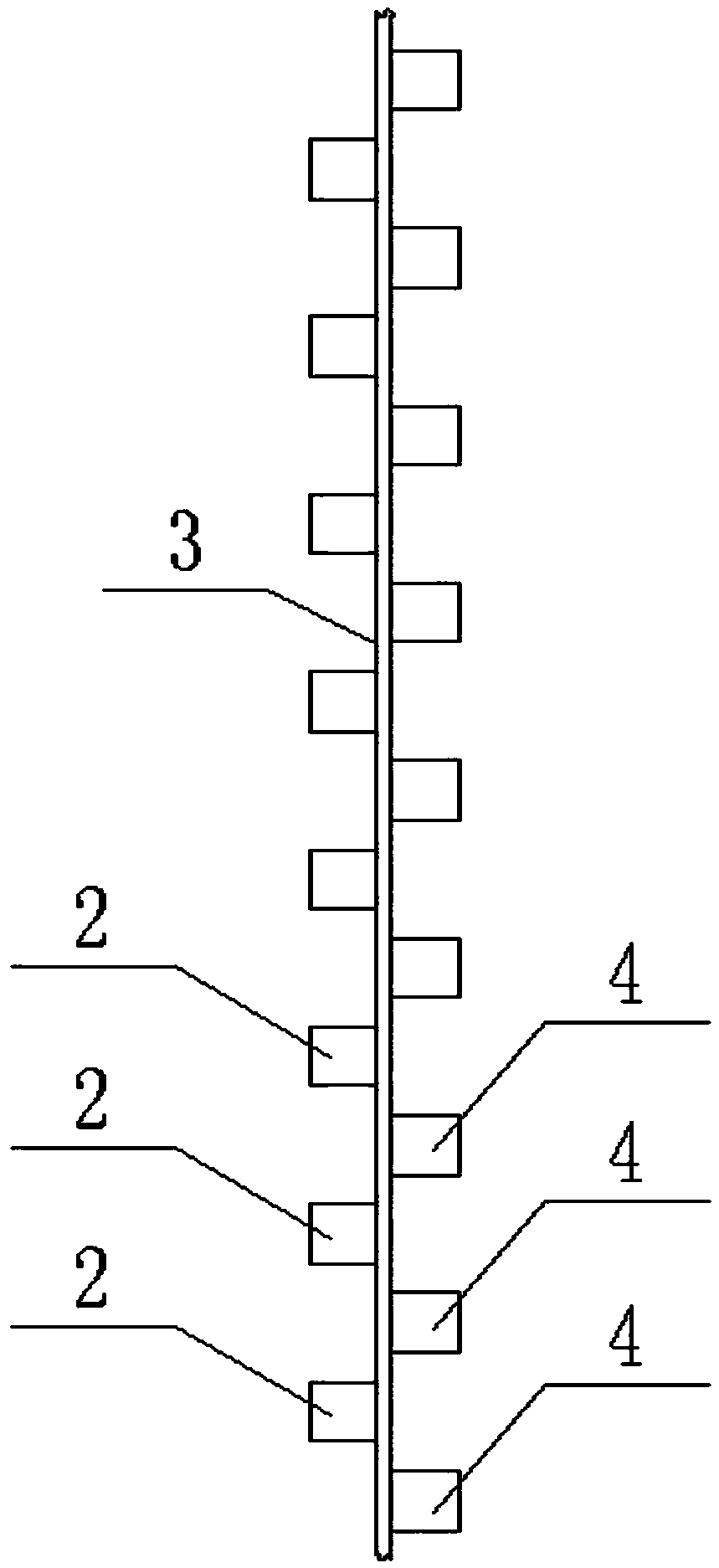

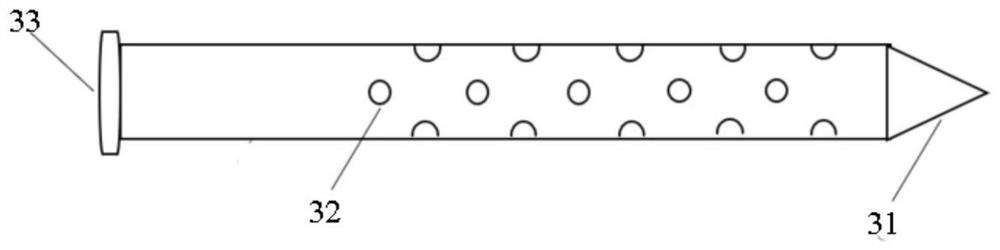

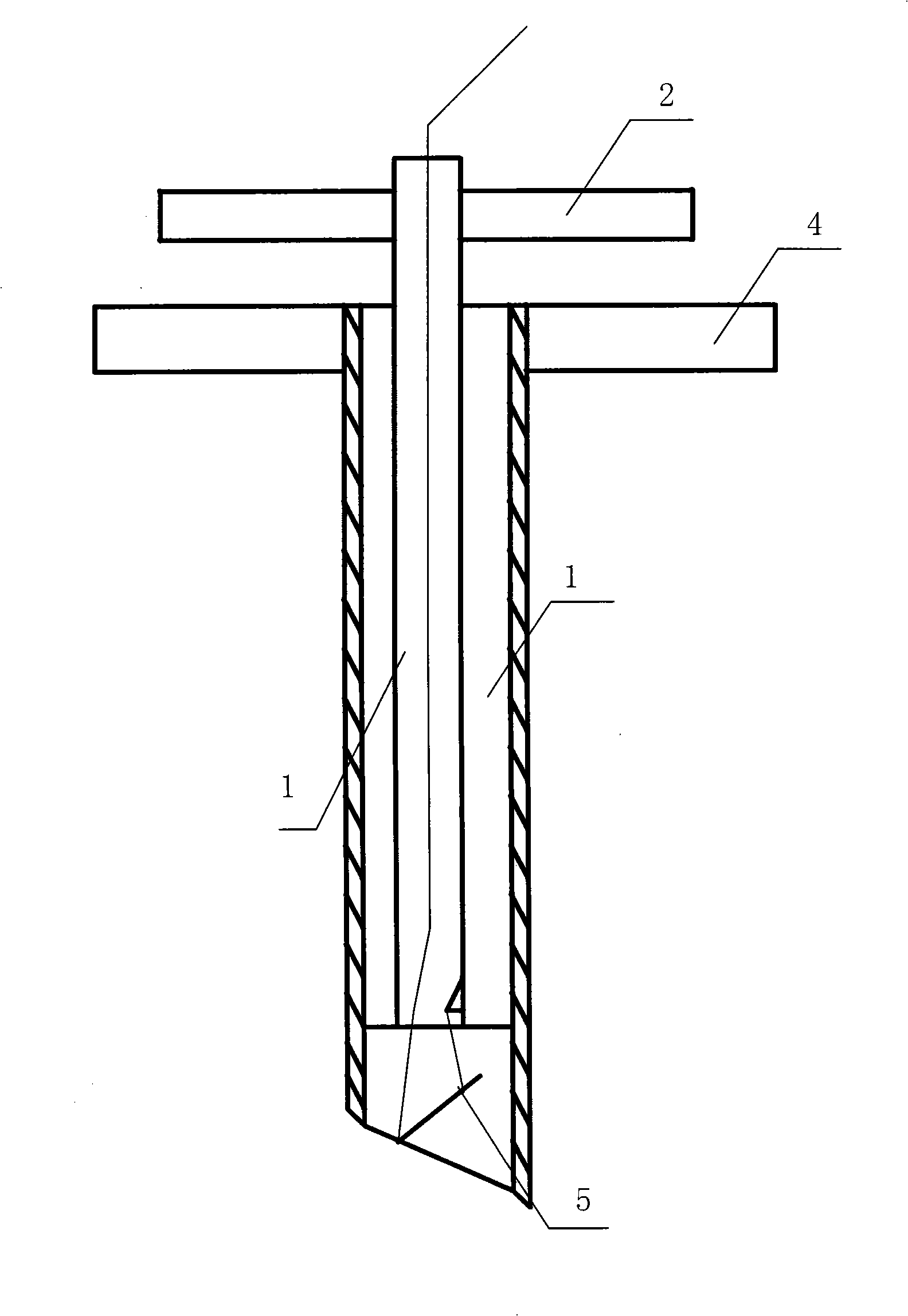

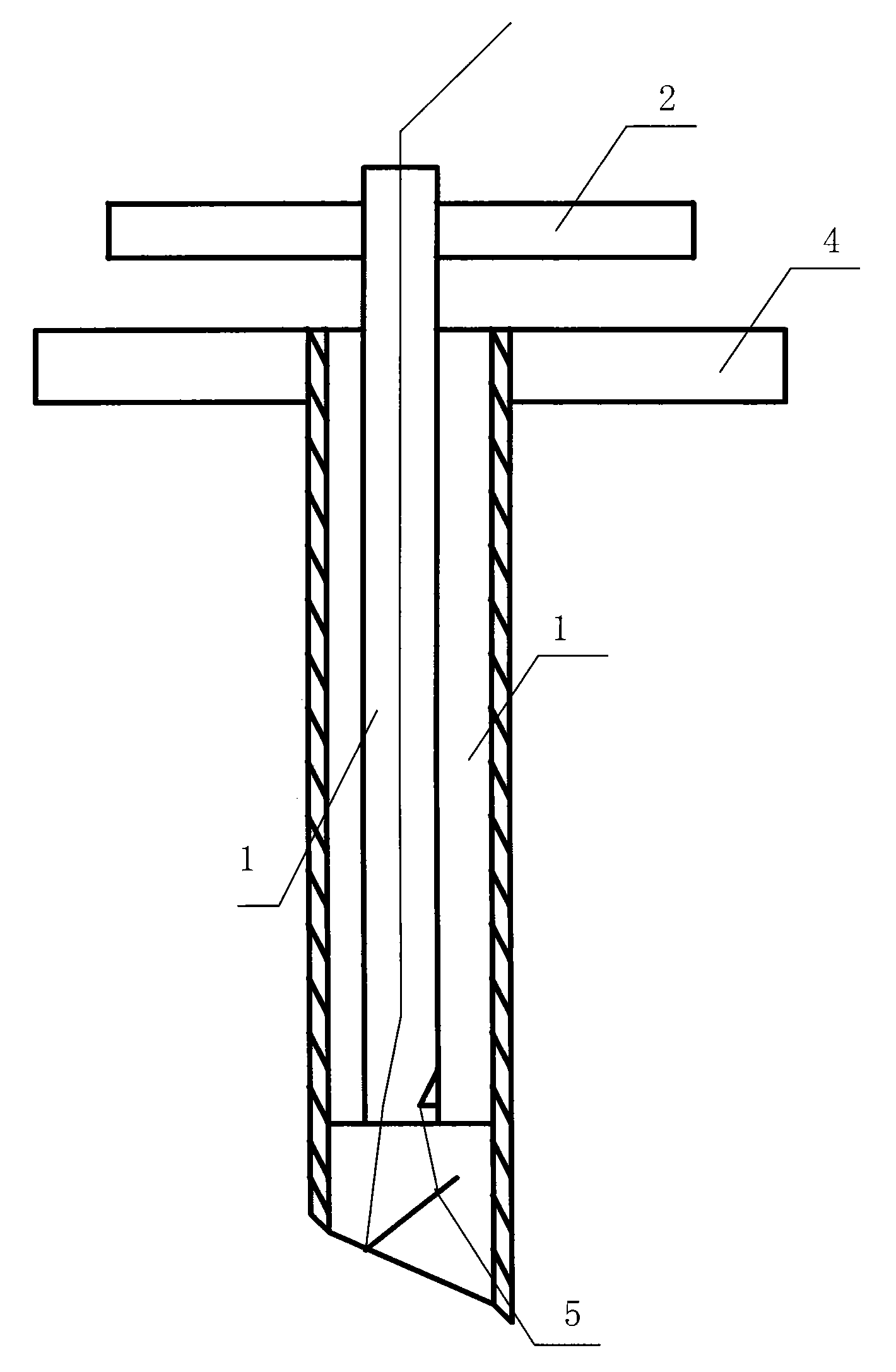

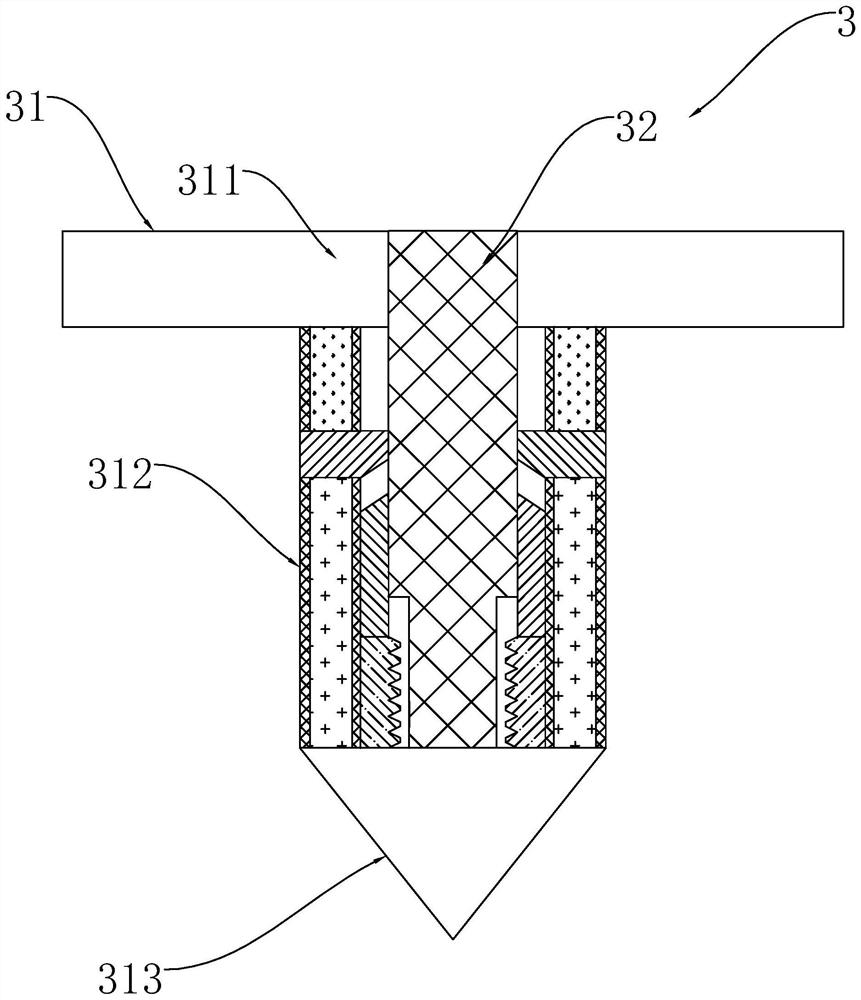

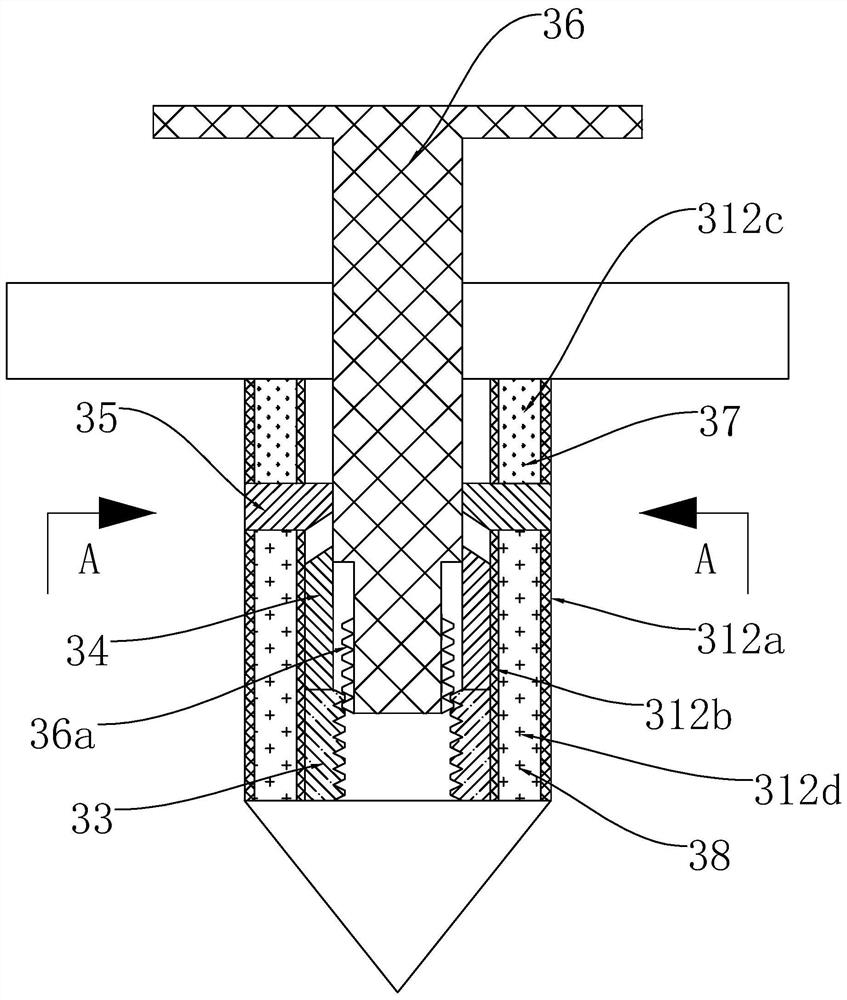

Dry sand sampling drill

InactiveCN102465516APrevent slumpSampling is simple and convenientIn situ soil foundationDry sandDrill bit

The invention relates to a dry sand sampling drill. An internal drill bit is connected with an internal drill handle, an external drill bit is connected with an external drill handle, the internal drill bit is inserted into the external drill bit and is provided with a baffle, one end of the baffle is connected with the internal drill bit, and the other end of the baffle penetrates through the internal drill bit to extend out via a rope. The external drill bit of the external drill is inserted into sand, and the sliding collapse of walls of sand flow holes can be avoided due to the external drill; and the inner wall of the internal drill is a hollow cavity, the movable baffle is arranged in the cavity, and when the external drill is inserted into the sand, the internal drill is inserted into the external drill, the movable baffle is opened and is then closed through pulling the rope when drilling is carried out to a certain depth, and thus the sand can be removed. Therefore, the sampling is convenient and simple, and labor can be saved.

Owner:SHAANXI LONGHAI ENG CONSTR

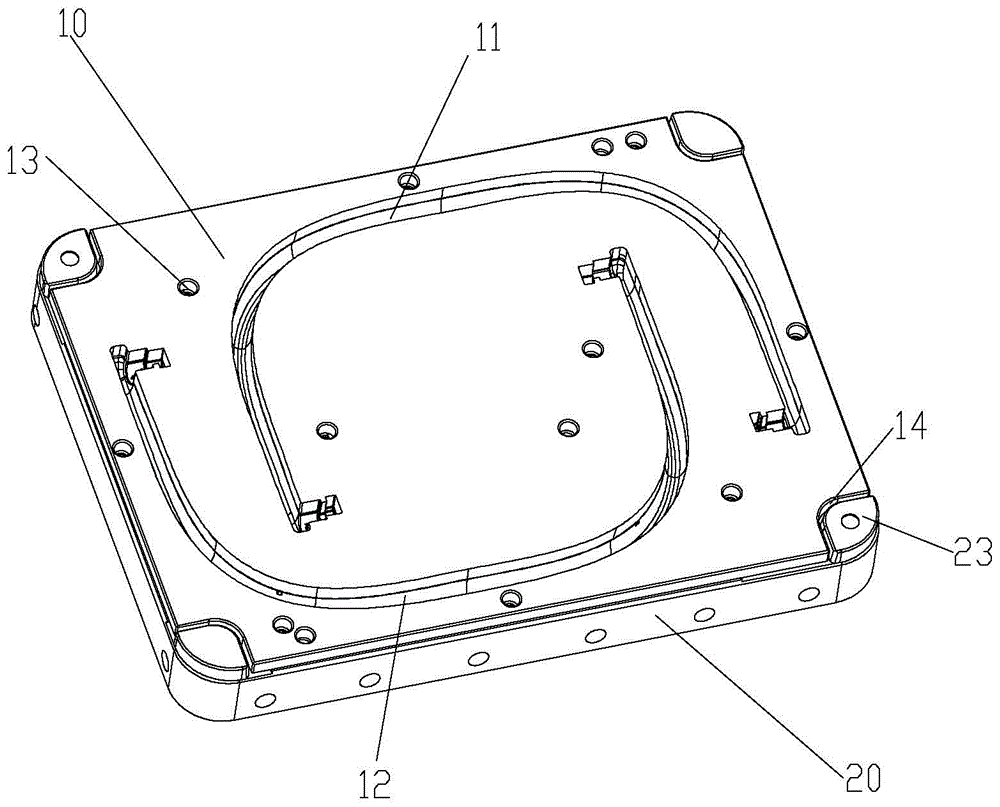

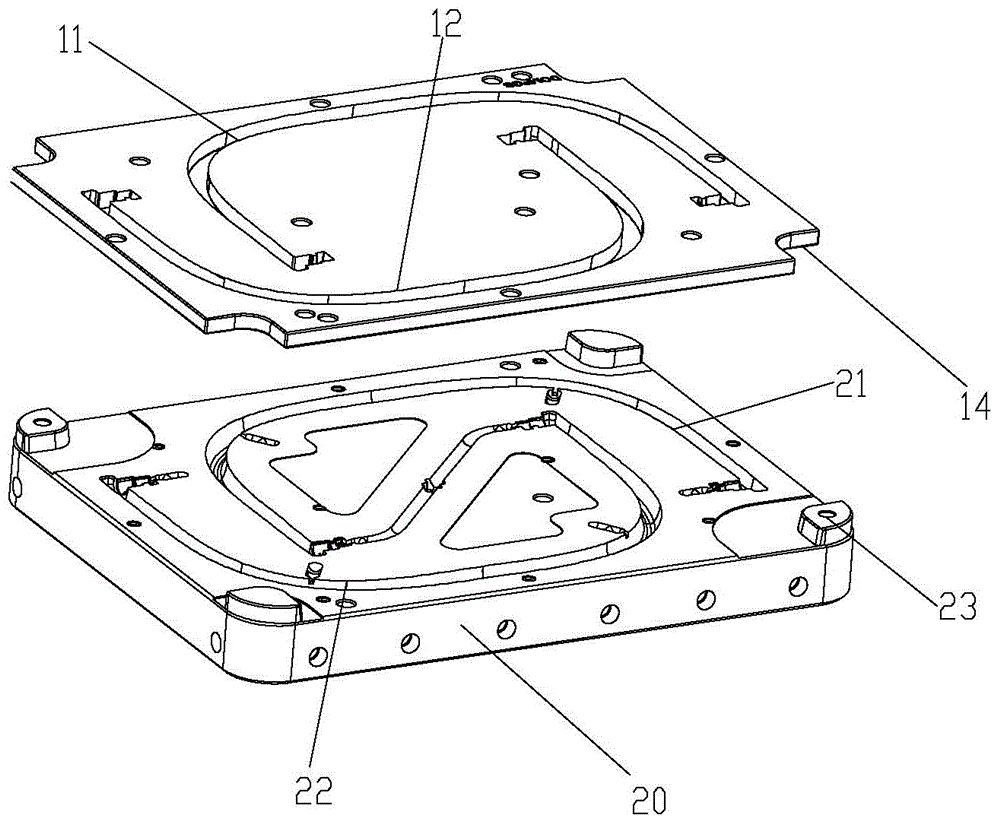

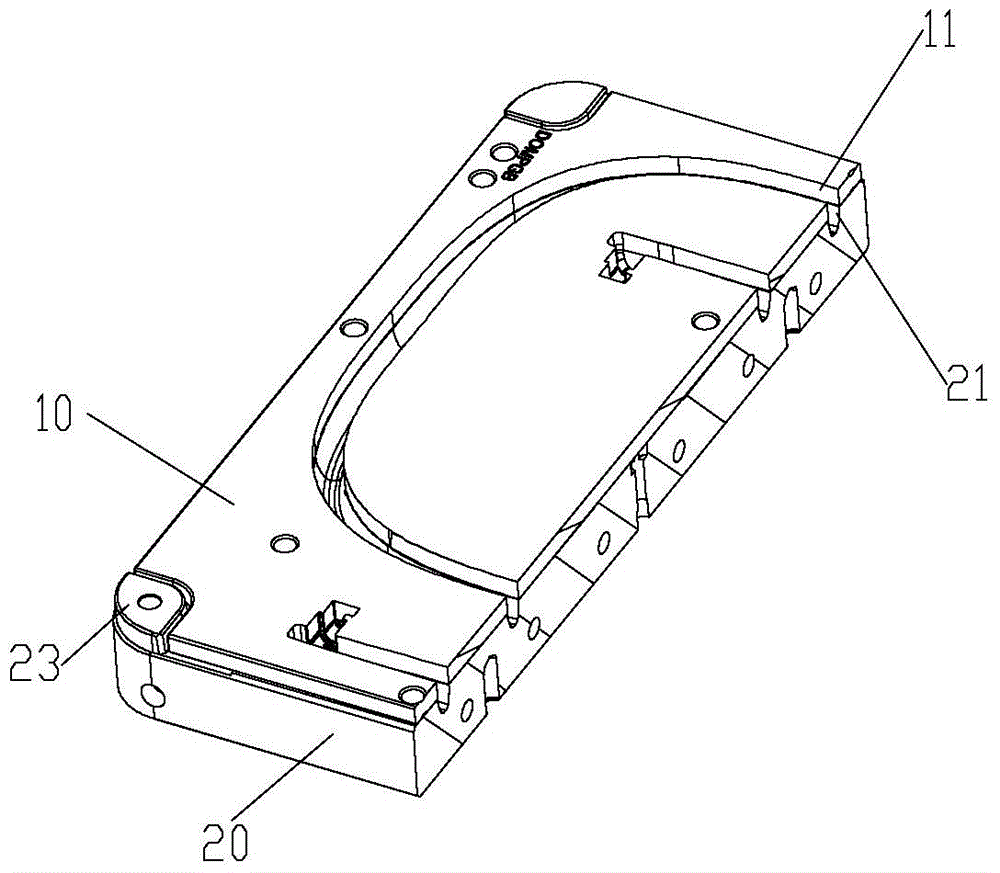

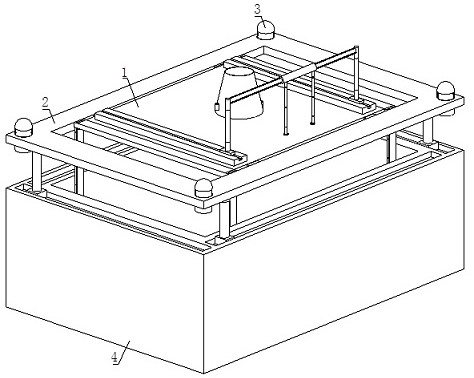

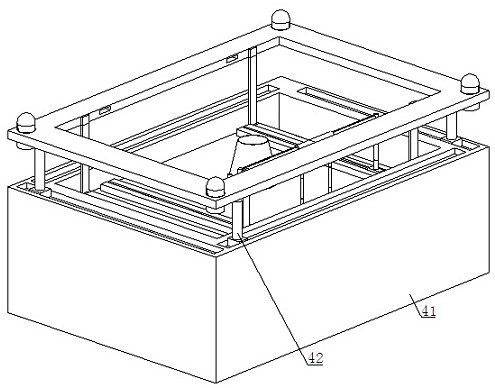

Mold polishing protection device and mold polishing method

The invention provides a mold polishing protection device and a mold polishing method. The mold polishing protection device comprises a protecting plate, the protecting plate is fixedly arranged on a mold to be polished, the mold to be polished is provided with a cavity for forming injection-molded pieces, the protecting plate is provided with a hollow-out part corresponding to the cavity, and the side wall surface of the hollow-out part is aligned to the side wall surface of the cavity. The protecting plate can avoid corner collapse of the mold to be polished and accordingly improve the mold yield rate.

Owner:GREE ELECTRIC APPLIANCES INC

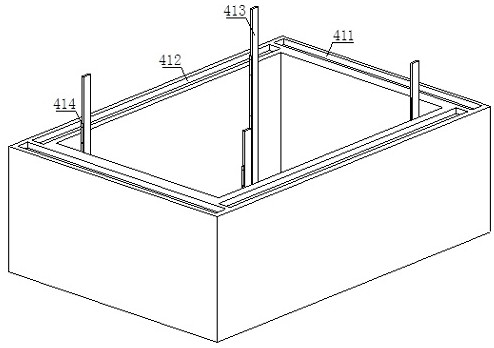

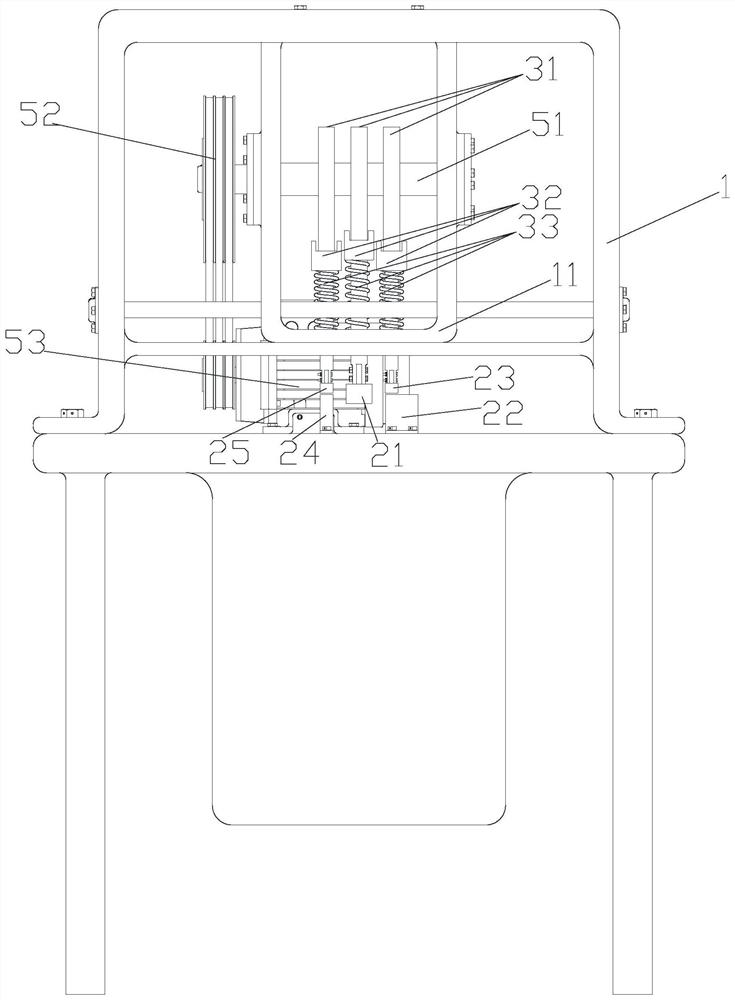

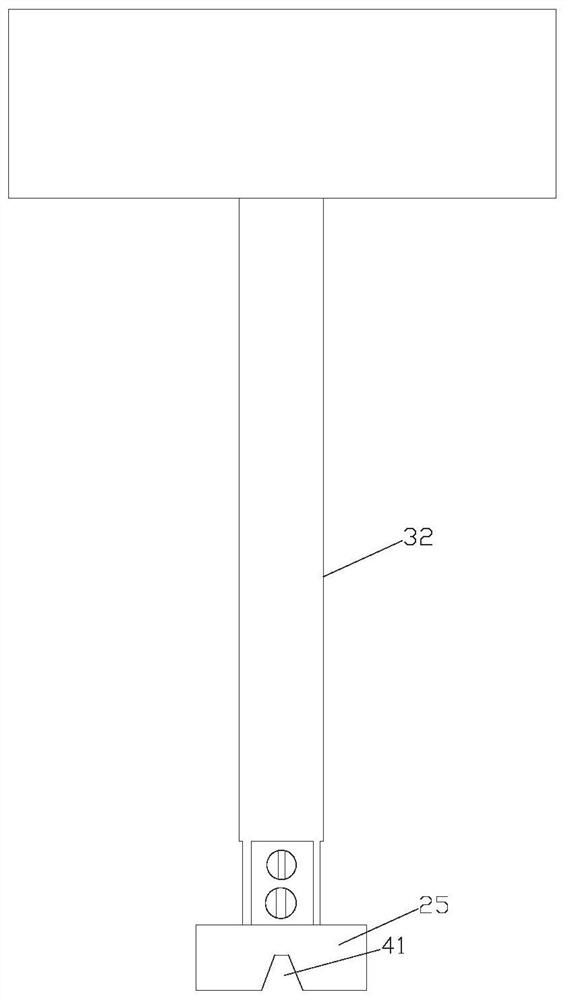

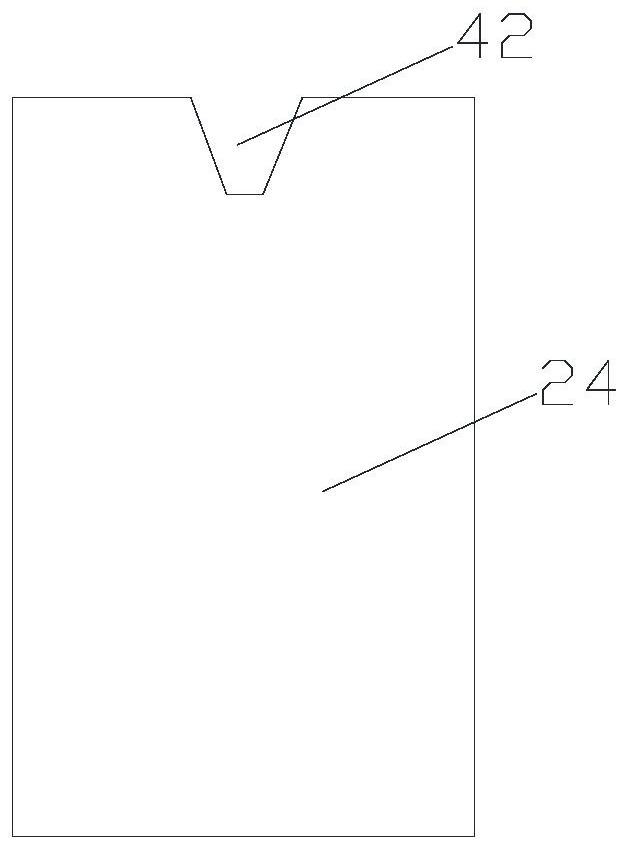

Concrete slump detection device

ActiveCN112255394AReduce slump detection errorReduce detection errorMaterial testing goodsWater storageCommunicating vessels

The invention discloses a concrete slump detection device which comprises a main body mechanism, an adjusting mechanism, an observing mechanism and a supporting mechanism, the adjusting mechanism is arranged on the outer surface of the main body mechanism, the observing mechanism is arranged on the outer surface of the adjusting mechanism, the supporting mechanism is arranged at the lower end of the adjusting mechanism, a communicating pipe and water storage barrels can form a communicating vessel, the communicating vessel principle is utilized, under the same atmospheric pressure, the liquidlevel heights of the two horizontal water storage barrels should be the same, when a conical barrel is placed, whether the conical barrel is in the horizontal state or not can be observed through thewater storage barrels, a fine adjustment mechanism is arranged at the upper end of the main box body, a fine adjustment block is fixedly installed at one end of a supporting column, a top seat is arranged at the other end of the supporting column, a threaded rod is arranged on one side of the supporting column, the supporting column is movably connected with a top seat through the threaded rod, the supporting column is connected with the adjusting sleeve plate through the top seat, and if not, adjustment is conducted through rotation of the top seat, so that the conical barrel is in a horizontal state, and slump detection errors are reduced.

Owner:日照市市政工程质量检测有限公司

Metal bar clamping type double-section shearing blanking device and blanking method

The invention discloses a metal rod clamping type double-section shearing blanking device and a blanking method. The device comprises a shell, a pressing discharging unit and a cam mechanism. The pressing discharging unit comprises a cutter, a first cushion block, a first pressing block, a second cushion block and a second pressing block. The cam mechanism comprises a first cam assembly, a second cam assembly and a third cam assembly; and the first cam assembly, the second cam assembly and the third cam assembly each comprise a cam, a compression state spring and a driven rod. The first pressing block is fixed to the driven rod of the first cam assembly. The cutter is fixed on the driven rod of the second cam assembly. The second pressing block is fixed to the driven rod of the third cam assembly. The cutter comprises a cutter body and two cutter edges; and a through hole is formed in the cutter body. According to the metal rod clamping type double-section shearing blanking device, clamping type double-section shearing blanking of the metal bars can be achieved, the bars are directly blanked after being sheared, and the blanking working efficiency is improved.

Owner:XIAN UNIV OF SCI & TECH

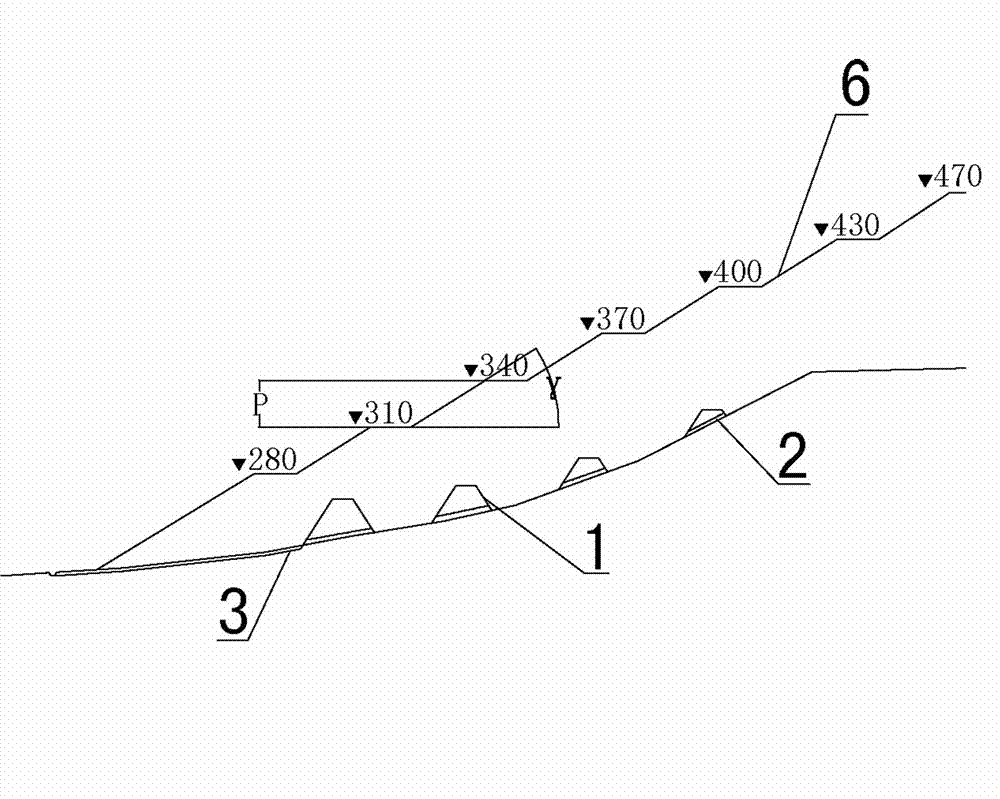

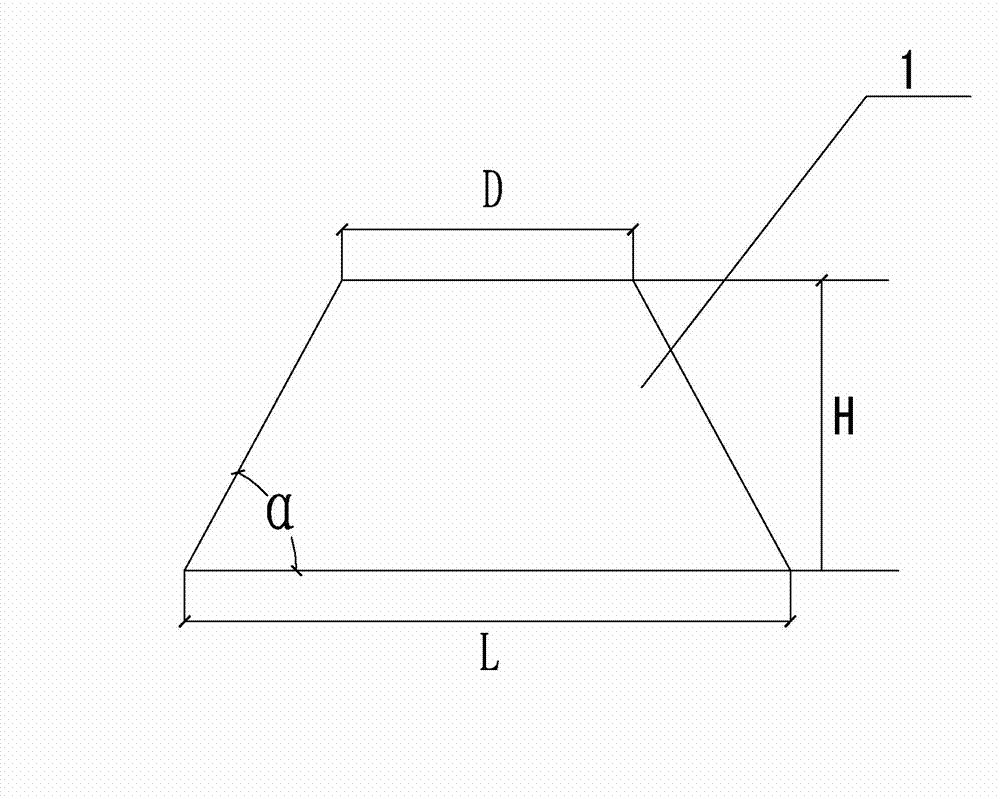

Process for constructing substrate dam of refuse dump

The invention relates to a process for constructing a substrate dam of a refuse dump, which comprises the following steps that: (1) a ladder-shaped substrate dam is constructed vertical to the gradient direction of a refuse dump within the range of the refuse dump, wherein the substrate dam is constructed by hard stone blocks and concrete, and the substrate dam is an isosceles trapezoid; (2) the position of the dam foundation of the substrate dam is provided with a water drain hole, and the position of the water drain hole of the substrate dam at the bottommost position of an elevation is excavated with a water drain ditch; and (3) a water guide ditch is excavated between the water drain ditch and a water accumulation pool, an outlet of the water drain ditch of the substrate dam is connected with the water guide ditch, an outlet of the water guide ditch is connected with the water accumulation pool, and the water of the water drain ditch is gathered at the water accumulation pool by the water guide ditch. The process for constructing the substrate dam of the refuse dump has the following advantages that: because the position of the dam foundation of the substrate dam is provided with the water drain hole and the water drain ditch is also excavated at the position of the water drain hole of the substrate dam at the bottommost position of the elevation according to the process for constructing the substrate dam of the refuse dump, the occurrence of the phenomena of landslide of the refuse dump and collapse of the refuse dump, which are caused because of the immersion of the refuse dump in the accumulated water, is effectively prevented according to the process for constructing the substrate dam of the refuse dump, and the accumulated water of a substrate of the refuse dump is also gathered and stored for other purposes.

Owner:ANSTEEL GRP MINING CO LTD

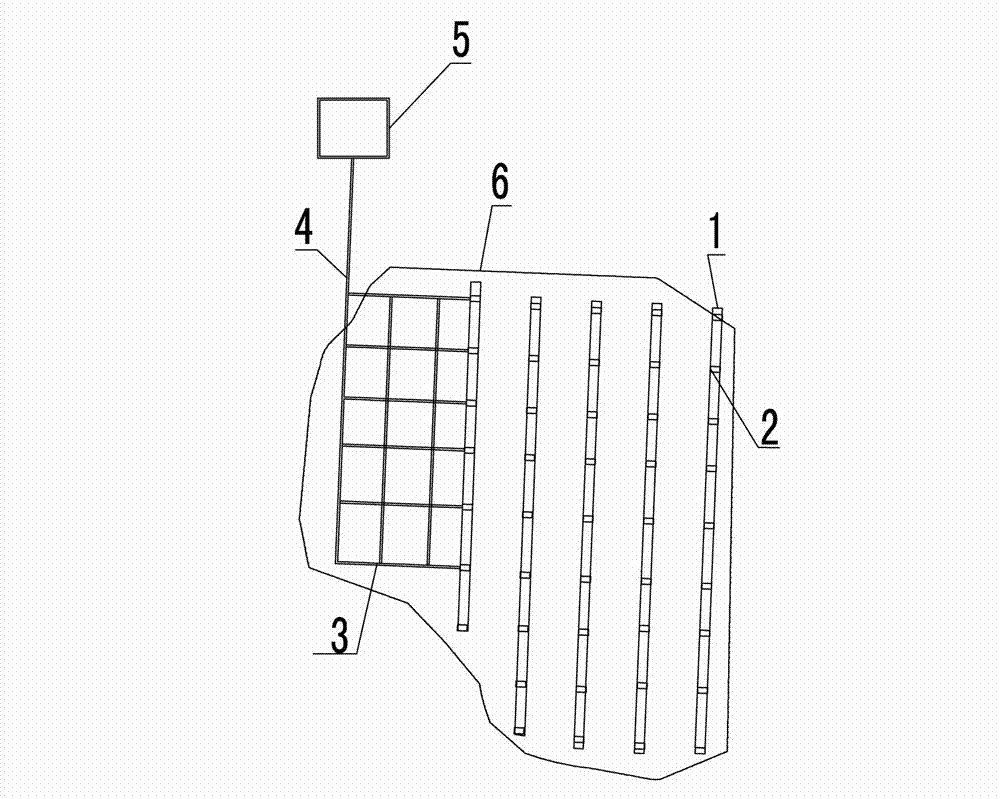

Slope protection device for strip mine dump and method thereof

ActiveCN112726645ALooseness can be monitoredMonitor for loosenessExcavationsBulkheads/pilesArchitectural engineeringScrew thread

The invention discloses a slope protection device for a strip mine dump. The slope protection device comprises a plurality of protective nets and T-shaped protective rods, wherein the protective nets are connected in a criss-cross mode, and the T-shaped protective rods are arranged at the criss-cross connecting joints of the protective nets. Each T-shaped protective rod comprises a fixing shell, an internal thread circular ring, an axial inclined block, a radial inclined block, and an operating rod; the threaded section of the operating rod is in threaded connection with the internal thread circular ring and drives the internal thread circular ring to move in the axial direction of the fixing shell so as to sequentially push the axial inclined block and the radial inclined block to slide; and the side wall of the fixing shell is filled with a liquid component which can be foamed and subjected to cross-linking polymerization reaction when encountering water. The slope protection device is convenient and fast to operate, the loosening condition of a side slope of the mine dump can be monitored, the landslide phenomenon of the side slope of the mine dump can be effectively prevented, and the use requirement for stability of the side slope of the strip mine dump is met. The invention further discloses a slope protection method for the strip mine dump.

Owner:内蒙古煤炭科学研究院有限责任公司

Low-density flame-retardant polyethylene cable material

InactiveCN103374165AImprove flame retardant performancePrevent slumpInsulated cablesInsulated conductorsAntioxidantLow density

The invention relates to a low-density flame-retardant polyethylene cable material. The low-density flame-retardant polyethylene cable material is characterized by being prepared from the following ingredients in parts by weight: 20-25 parts of polyethylene, 70-75 parts of modified magnesium hydroxide, 0.5-1 part of antioxidant and 1-1.5 parts of lubricant. According to the low-density flame-retardant polyethylene cable material, the modified magnesium hydroxide is selected as a flame retardant; and after the modified magnesium hydroxide is added, the material can have excellent flame retardance, the material can be effectively prevented from being subjected to a lowering phenomenon during burning, and fire can not be spread even if electric wire cables are in a bunched laying state.

Owner:鲍联

Metal plate shearing die

The invention discloses a metal plate shearing die. The metal plate shearing die structurally comprises an upper die plate and a lower die plate, wherein the upper die plate comprises an upper die plate seat and an upper die fixed plate, the upper die fixed plate is fixedly connected to the surface of the upper die plate seat, an upper die anti-side block, an upper die cutting edge and an upper die pressing plate are arranged on the upper die fixed plate in sequence, and guide sleeves are arranged on both ends of the upper die fixed plate; the lower die plate comprises a lower die plate support frame bottom plate, a lower die support frame and a lower die plate seat, the lower die plate seat is fixedly connected to the lower die plate support frame bottom plate by virtue of a lower die plate support frame, a support plate, a lower die cutting edge adjusting block, a lower die cutting edge and a sliding plate are arranged on the lower die plate seat in sequence, a plate positioning device and a plate pulley are arranged on the support plate, guide posts are fixedly arranged on both ends of the lower die plate seat, and upper die support mechanisms are arranged on both sides of the guide posts. The metal plate shearing die has the advantages of high shearing precision and durability of the cutting edges and can be used for shearing the plate with the width of 300 to 450 mm.

Owner:长春事达汽车零部件有限公司

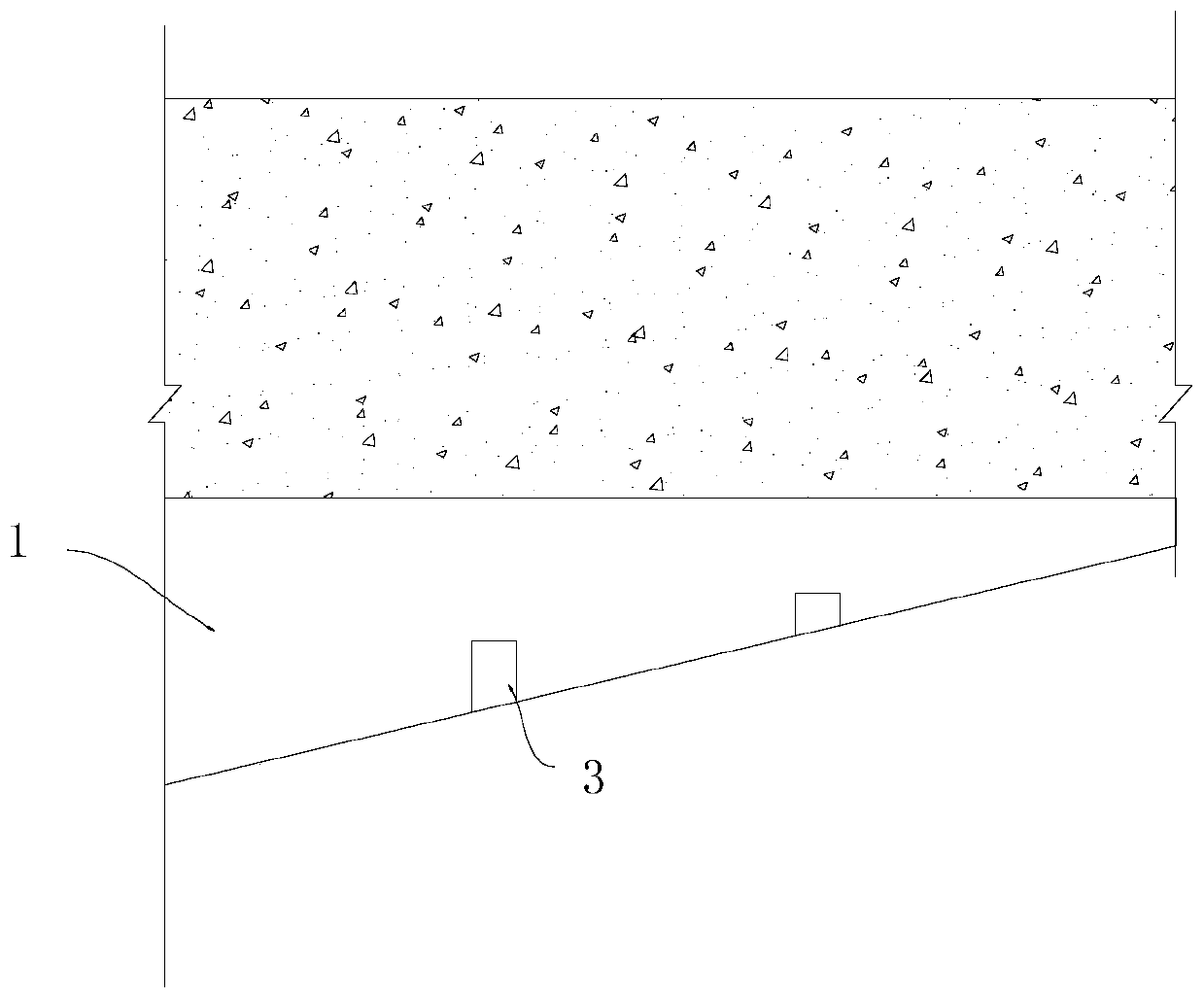

Construction method for dismounting sandwich linings of operating high-speed rail tunnels

ActiveCN110410102ALighten the loadProtection strengthUnderground chambersTunnel liningSlagEngineering

The invention discloses a construction method for dismounting sandwich linings of operating high-speed rail tunnels, and belongs to the field of tunnel lining construction. The method comprises the following steps of determining a dismounting area of a sandwich lining and erecting a temporary protection frame below a to-be-dismounted sandwich lining; constructing multiple groups of annular cuttingseams for the sandwich lining along circumference of a tunnel by utilizing a cutting machine, and constructing multiple groups of longitudinal cutting seams for the sandwich lining along the longitudinal direction of the tunnel; dismounting sand lining blocks obtained through cutting of the longitudinal cutting seam and the annular cutting seams in sequence, cleaning the lining surfaces of the newly exposed parts of the tunnel after the sandwich lining is eliminated, and fixing the temporary protection frame on the lining of the newly exposed part; and spraying a repair layer at the damaged part of the newly exposed lining of the tunnel and then dismounting the temporary protection frame. The method is capable of dismounting the sandwich linings without influencing the existing traffic circulation, and avoiding the lining surfaces from the phenomena such as slag drop and the like to influence the high-speed rail transportation, thereby ensuring the operation safety after the skylightis finished.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com