Binder system for honeycomb ceramic bodies and method for producing honeycomb bodies

A binder system and binder technology, used in ceramic products, manufacturing tools, ceramic extrusion dies, etc., to achieve the effects of low exothermic strength, reduced firing cracks, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

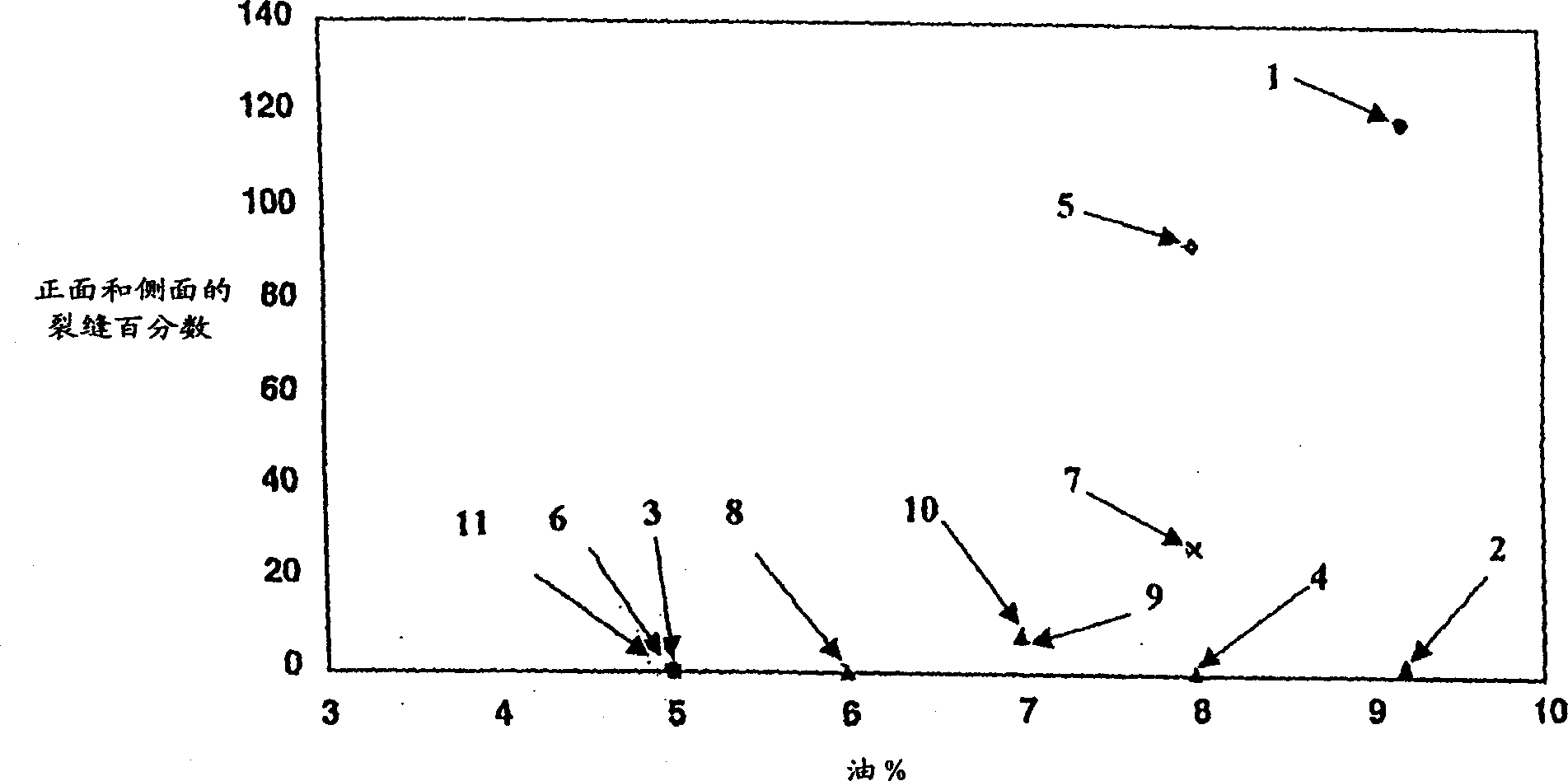

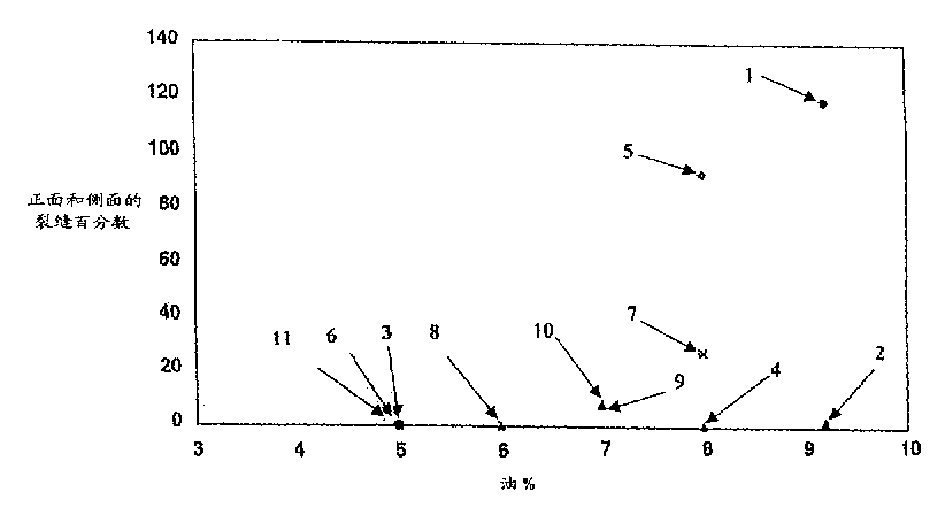

Embodiment 1-11

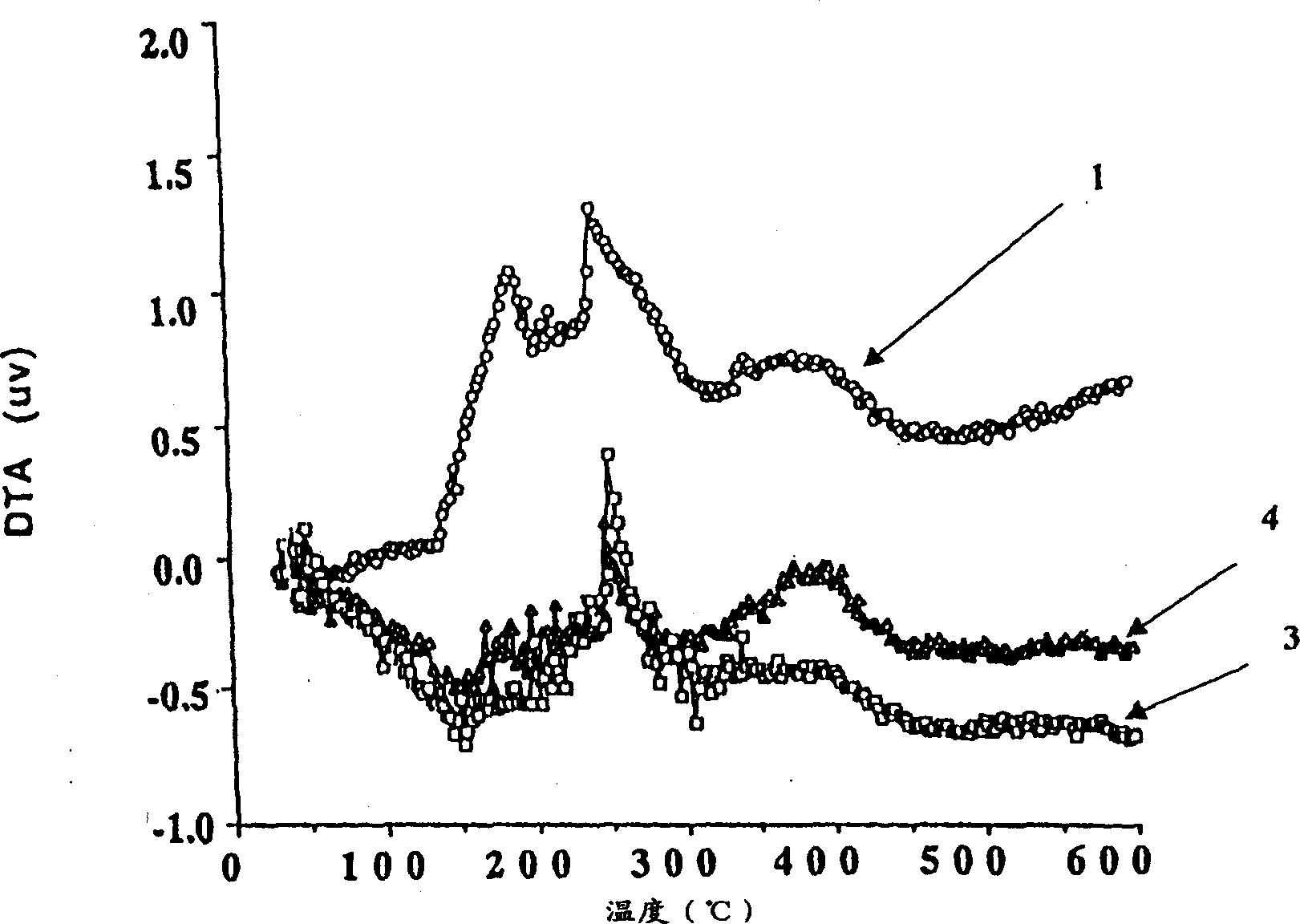

[0049] Various inorganic powder batch mixtures suitable for making cordierite ceramic bodies are listed in Table 1, expressed in parts by weight. Each of Compositions 1-11 was prepared by compounding and dry blending together the components of the specified inorganic mixture as shown in Table I; Y and Z differ in the fine and coarse oxidation of the alumina component aluminum ratio. The amount of binder system listed in Table II was then added to each inorganic dry blend and further mixed to form a plasticized ceramic batch mixture. Two of the 11 compositions were used for comparison. Each of the 11 different plasticized ceramic batch mixtures contained 100 parts by weight inorganic powder batch mixture and varying amounts of binder system (up to 39.5 parts by weight), as shown in Table II. Table III lists various non-solvent (ie, various types of oil) components used in the examples, indicated by symbols A-F. The carbon chain distributions and 90% recovery distillation tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com