Retaining wall for water conservancy project

A technology for water conservancy projects and retaining walls, applied in the field of retaining walls, can solve the problems of long construction period, difficult water use, poor strength, etc., and achieve the effect of beautifying the city, preventing collapse and preventing slumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

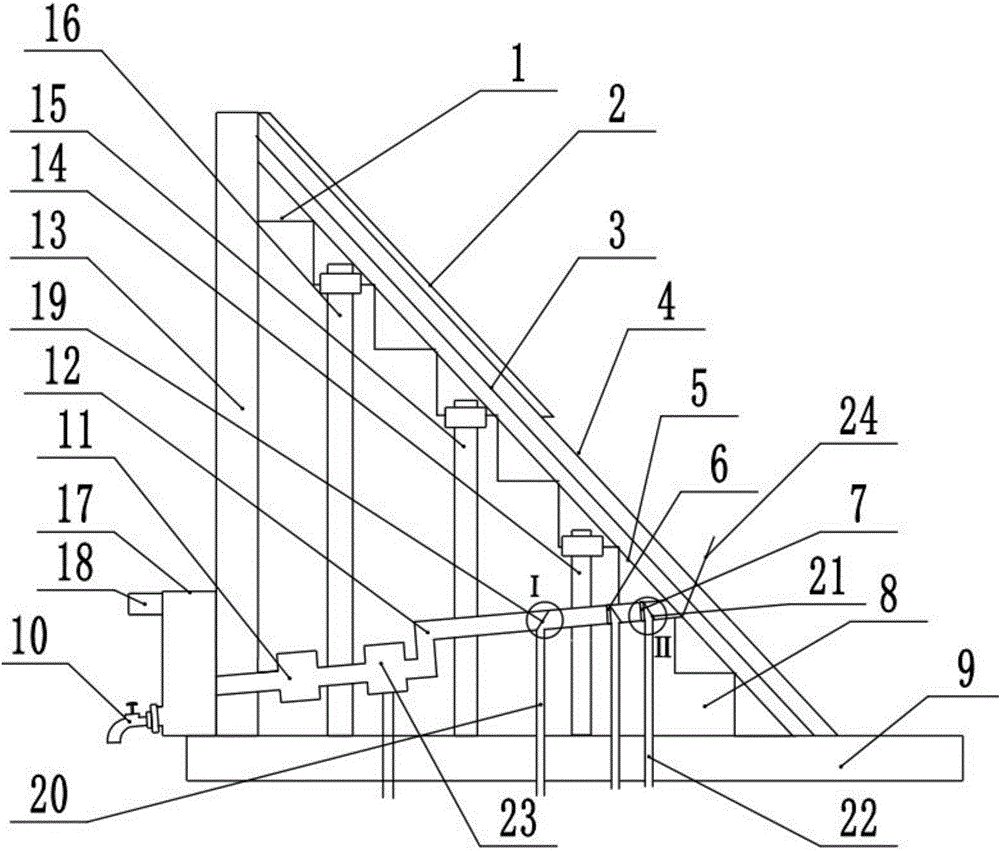

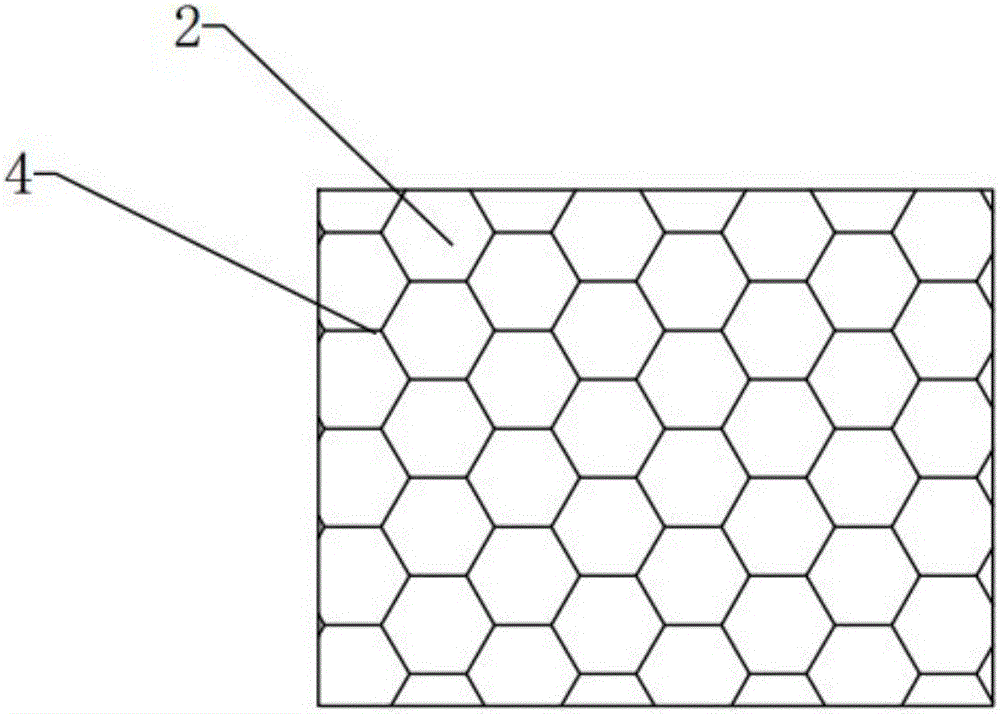

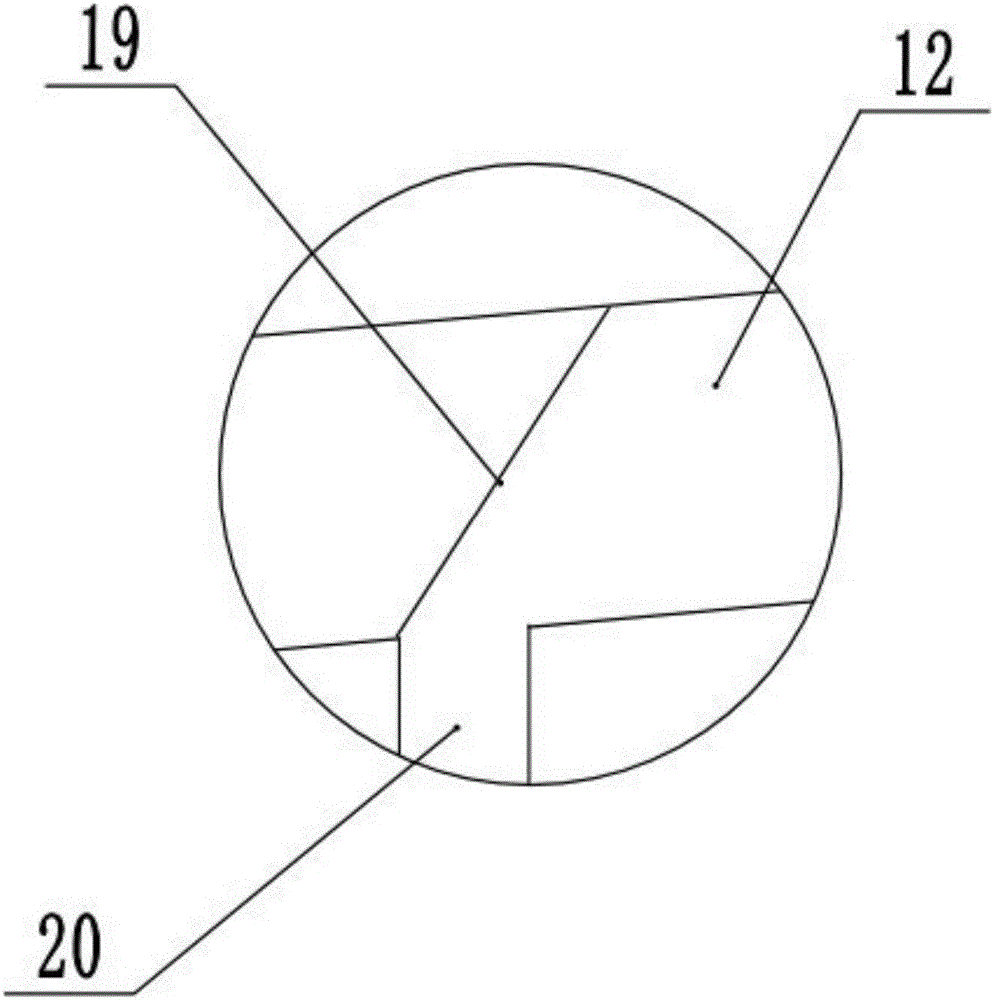

[0031] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment. The present invention relates to a retaining wall, more specifically a retaining wall for water conservancy projects, including a prism shape 1, a greening layer 2, and an anti-corrosion layer 3 , steel wire protective net 4, plain concrete layer 5, sediment filter II 6, sediment filter I 7, slope body 8, foundation 9, faucet 10, river water purification filter 11, water pipe 12, concrete wall 13, high strength Bolt Ⅰ14, high-strength bolt Ⅱ15, high-strength bolt Ⅲ16, water tank 17, overflow pipe 18, baffle 19, sewage pipe Ⅰ20, sewage baffle 21, sewage pipe Ⅱ22, water purification device 23 and water guide 24, which can prevent moisture The land is eroded to prevent collapse and slumping, and the water pipes in the retaining wall can lead the river water out, and the water source can be directly used through the river water purification filter, which is convenient for pedestrians to use water. G...

specific Embodiment approach 2

[0041] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment. This embodiment will further describe Embodiment 1. The angle between the water pipe 12 and the foundation 9 is an acute angle, and the water inlet end of the water pipe 12 is higher than the water outlet. . In this way, the water flow can flow out along the water pipe 12 under the action of gravity.

specific Embodiment approach 3

[0042] Combine below figure 1 , 2 , 3, 4, 5, 6, and 7 illustrate this embodiment. This embodiment will further illustrate Embodiment 1 or 2. The cross-sectional area of the water pipe 12 is greater than all sewage pipes I20, sewage pipe II22 and drain pipe 23- The sum of the cross-sectional areas of 3. In this way, all the water in the water pipe 12 will not be discharged from the sewage pipe I20, the sewage pipe II22 and the drain pipe 23-3, and some clean water will still flow into the water tank 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com