Drag chain

A technology of towline and chain plate, which is applied to towline. field, it can solve problems such as prone to failure, heavy drag chain wear, and high cost, and achieve the effect of preventing waist collapse and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

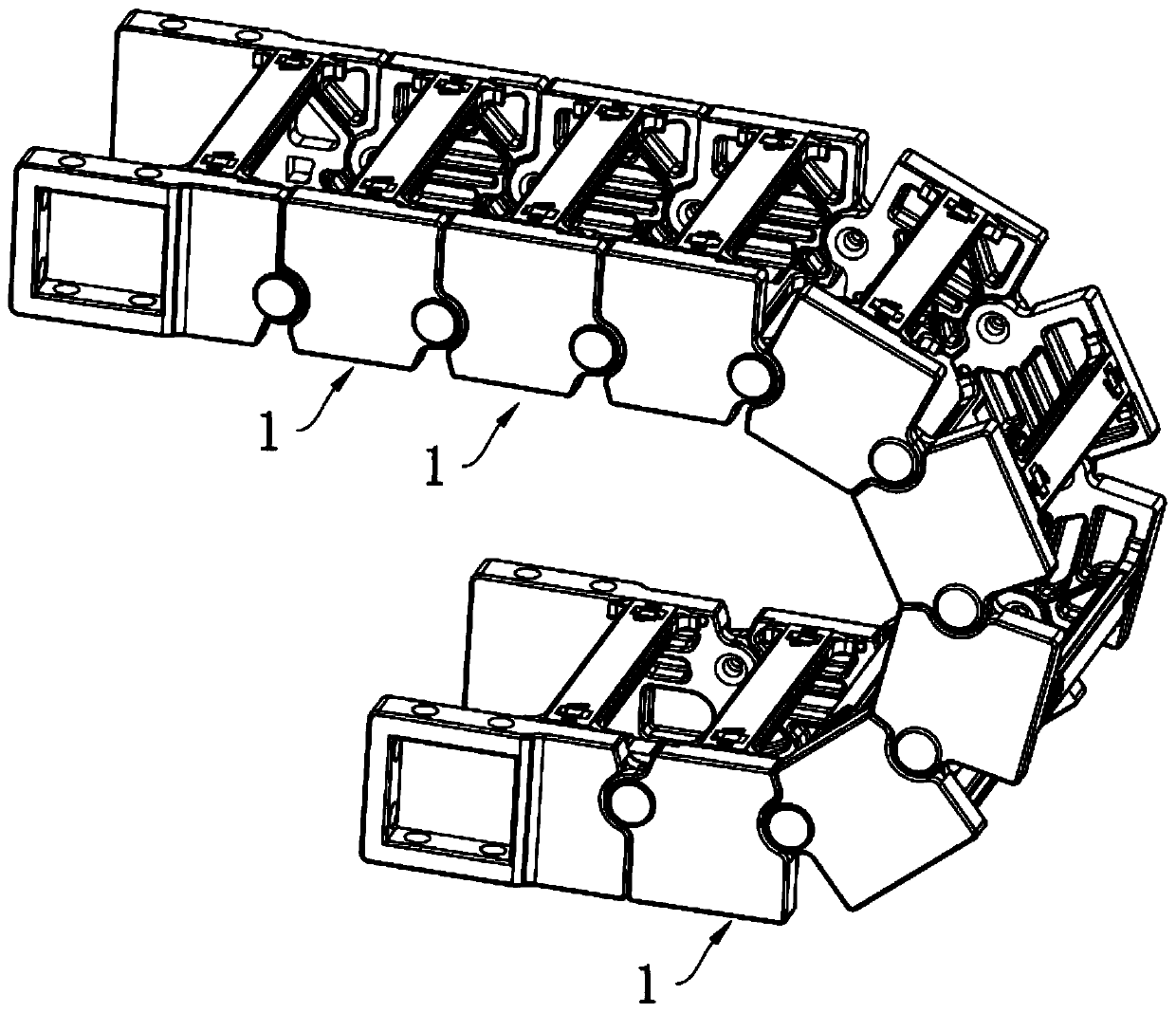

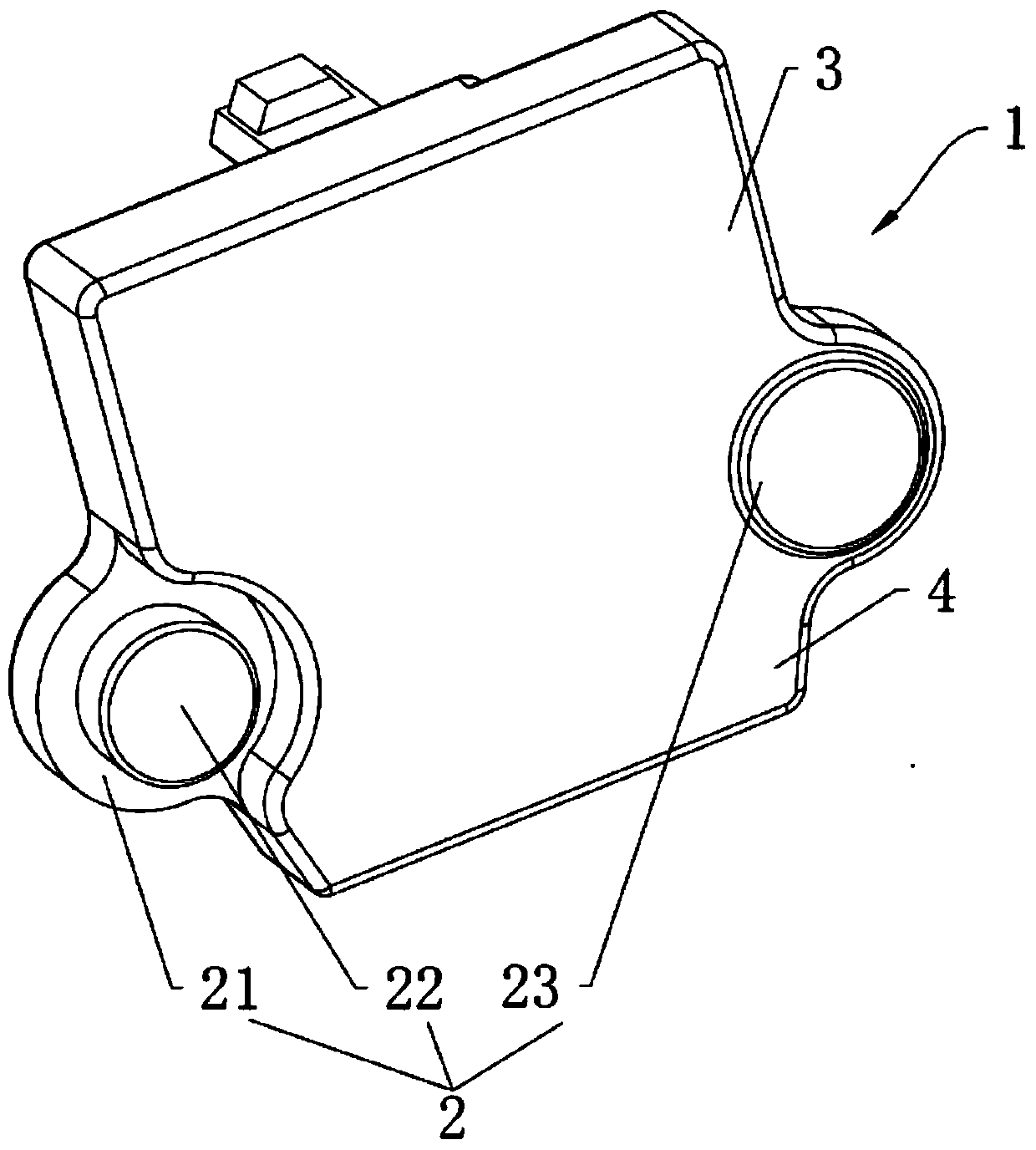

[0035] a drag chain, such as Figure 1-Figure 5 As shown, it includes a plurality of main body chain plates 1 and pins 2 arranged under one side of the main body chain plate 1. The main body chain plate 1 is sequentially hinged at the head and tail through the pins 2, and the axes of the plurality of pins 2 The connection line divides the main chain plate 1 into an upper chain plate 3 and a lower chain plate 4, one side end face of the upper chain plate 3 matches the other side end face of the upper chain plate 3, one side end face of the lower chain plate 4 matches the lower The other end surface of the chain plate 4 is matched, and the plurality of main body chain plates 1 are opened and closed under the support of the pin shaft member 2 .

[0036] In the specific implementation process, during the working process of the towline composed of multiple main chain plates 1, the towline moves horizontally and vertically with the carrier, and the towline itself maintains a level o...

Embodiment 2

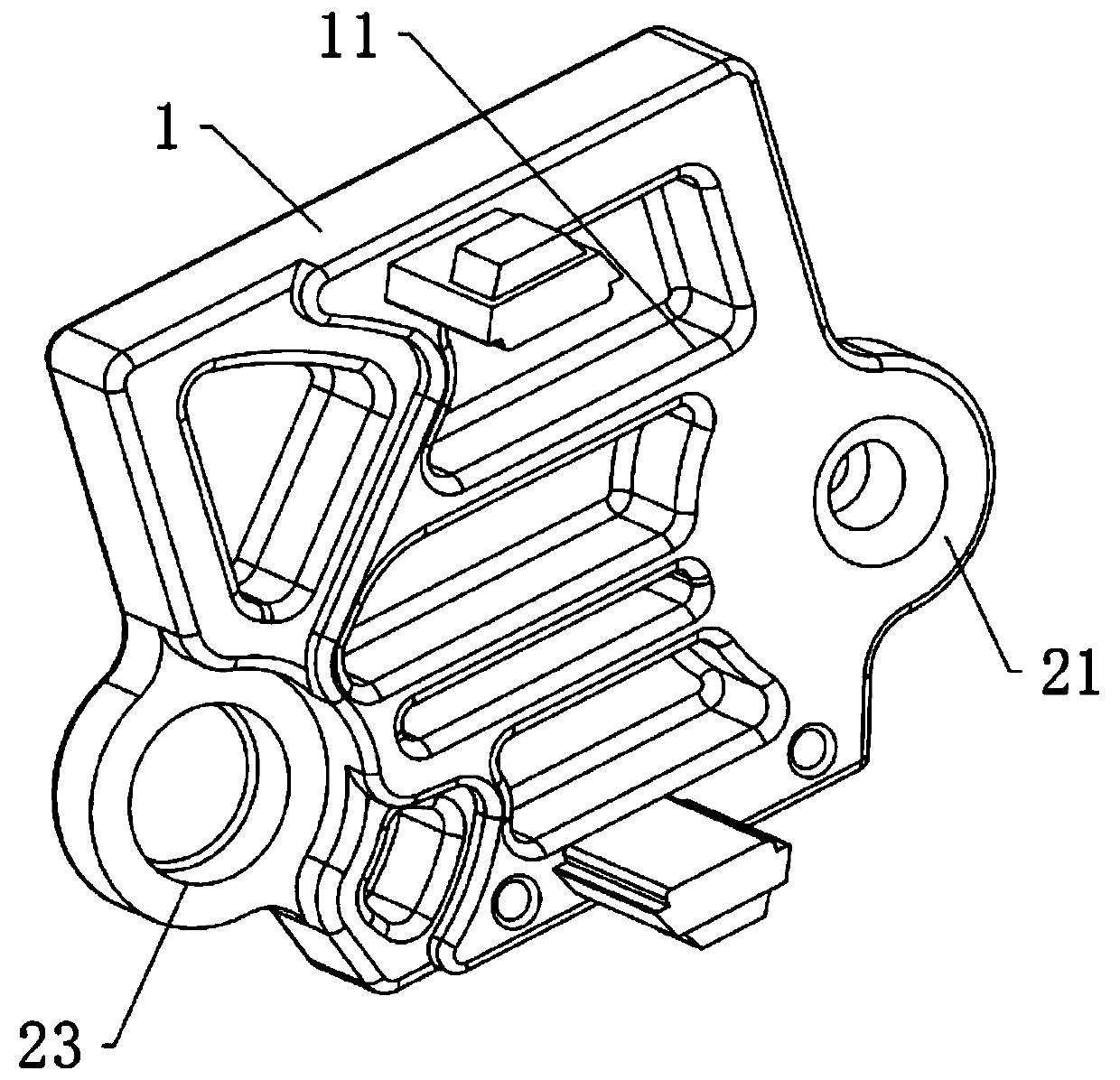

[0046] a drag chain, such as Figure 6-Figure 8 As shown, it includes a plurality of main body chain plates 1 and pins 2 arranged under one side of the main body chain plate 1. The main body chain plate 1 is sequentially hinged at the head and tail through the pins 2, and the axes of the plurality of pins 2 The connection line divides the main chain plate 1 into an upper chain plate 3 and a lower chain plate 4, one side end face of the upper chain plate 3 matches the other side end face of the upper chain plate 3, one side end face of the lower chain plate 4 matches the lower The other end surface of the chain plate 4 is matched, and the plurality of main body chain plates 1 are opened and closed under the support of the pin shaft member 2 .

[0047] Wherein, the pin shaft member 2 includes a pin shaft seat 24, a metal sheet 25 and a metal shaft 26. The pin shaft seat 24 is arranged on one side of the main body chain plate 1 and integrally connected with the main body chain pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com