High-pressure copper bar processing technique capable of overcoming punching corner collapse

A processing technology and high-pressure technology, applied in the field of high-voltage copper bar stamping, can solve problems such as stamping slump process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

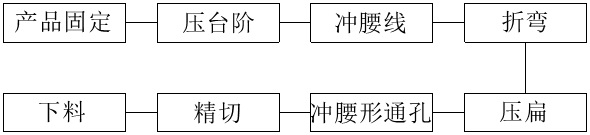

[0036] A high-voltage copper bar 3 processing technology for overcoming stamping slump, comprising the following steps:

[0037] Product fixing: Fix the high-voltage copper bar 3 to the lower mold 2.

[0038] The processing technology of the high-voltage copper bar 3 also includes a pressing step 8 arranged after the product is fixed and before bending, and step marks are pressed on the outer edges of both ends of the high-voltage copper bar 3, and then the steps 8 are punched out along the pressed step marks.

[0039] The processing technology of the high-voltage copper bar 3 also includes setting the waist line 9 after the product is fixed and before bending, and the waist line 9 required by the product is punched out at both ends of the middle part of the high-voltage copper bar.

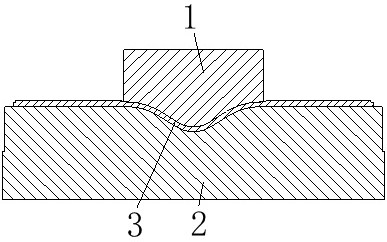

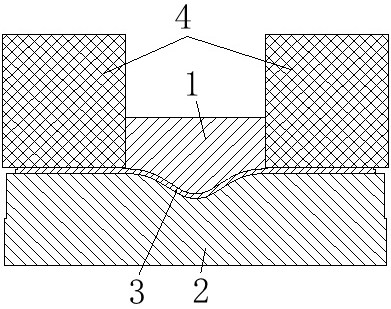

[0040] Bending: Utilize the pressing of the upper mold 1 and the lower mold 2 to bend the high-voltage copper bar 3 from the middle. At this time, the high-voltage copper bar 3 has a structure wi...

Embodiment 2

[0053] The present embodiment provides a high-voltage copper bar without sag produced by the above-mentioned processing technology.

[0054] refer to Figure 7 and Figure 8 , a high-voltage copper bar without slump, comprising a plate-shaped conductive body 11 and connecting parts 12 respectively arranged at both ends of the conductive body 11, the material of the conductive body 11 is metal, and preferably flexible copper, so as to facilitate For processing such as bending and stamping, the connection part 12 is provided with a horizontal connection surface, and the two sides of the connection part 12 are symmetrically provided with side end surfaces 13, and the side end surfaces 13 are arranged perpendicular to the connection surface. After being symmetrically stacked, it is fixed on the carrier and sealed with glue. The connecting part 12 is provided with a waist-shaped hole 16, and the connecting piece passes through the waist-shaped hole 16 and cooperates with the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com