Tin oxide nanomaterial and preparation method thereof

A nanomaterial, tin oxide technology, applied in tin oxide and other directions, can solve the problems of gas-sensing materials to be improved, low crystallinity, etc., and achieve the effects of high crystallinity, high product yield, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. prepare the tin chloride solution of 0.05mol / L with deionized water;

[0029] B. Sodium hydroxide is dissolved in deionized water to prepare the alkali solution of 4mol / L;

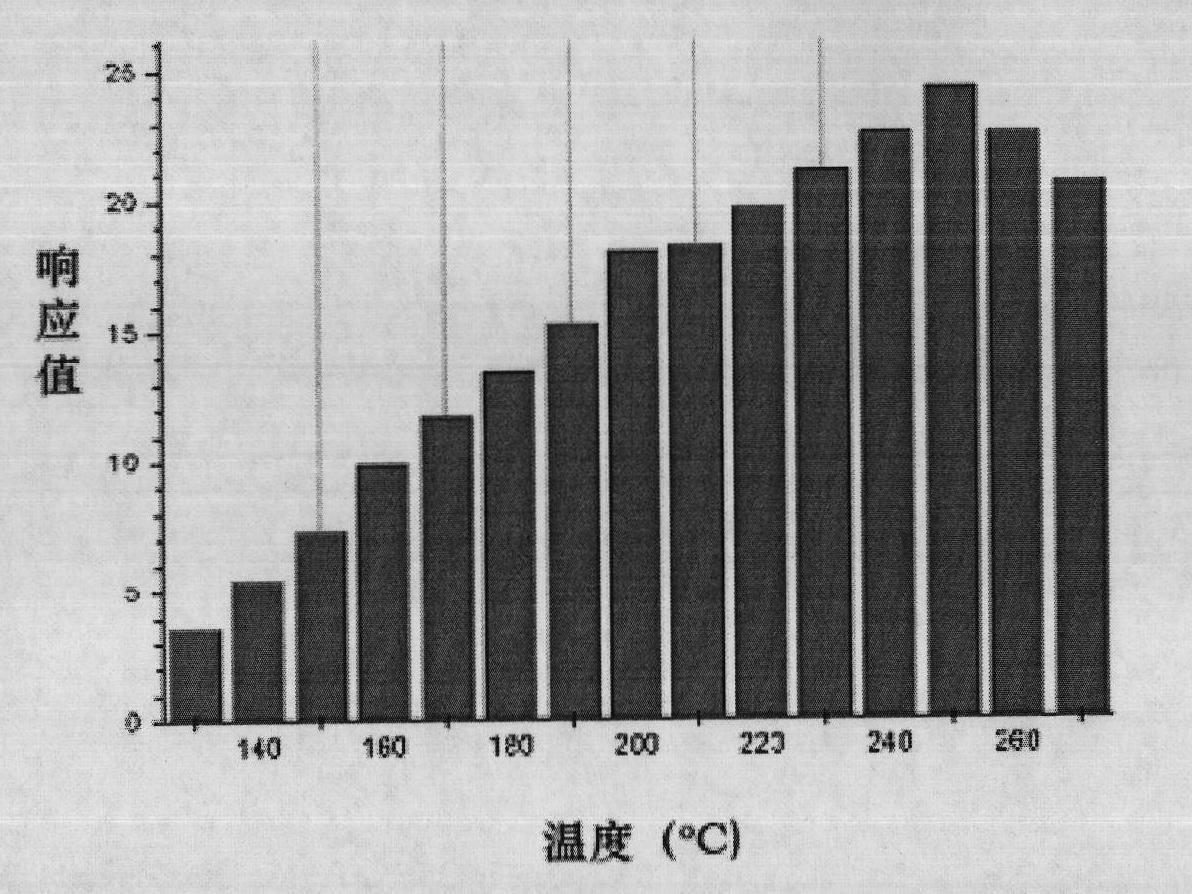

[0030] C. Under stirring, slowly add the alkali solution prepared in step B dropwise to the tin chloride solution prepared in step A until the molar ratio of tin ions and hydroxide ions in the solution is 1:8, then press the mixed solution volume Weigh an equal volume of absolute ethanol and mix it with the reaction solution, and disperse it with magnetic stirring for 5 minutes; transfer the dispersed reaction solution to a hydrothermal kettle, raise the temperature to 240°C, react at constant temperature for 30 hours, and cool naturally to room temperature. The product was filtered, washed with deionized water for 5 times, and then washed with absolute ethanol for 5 times, and then dried naturally to obtain a one-dimensional tin oxide nanomaterial with good crystallinity.

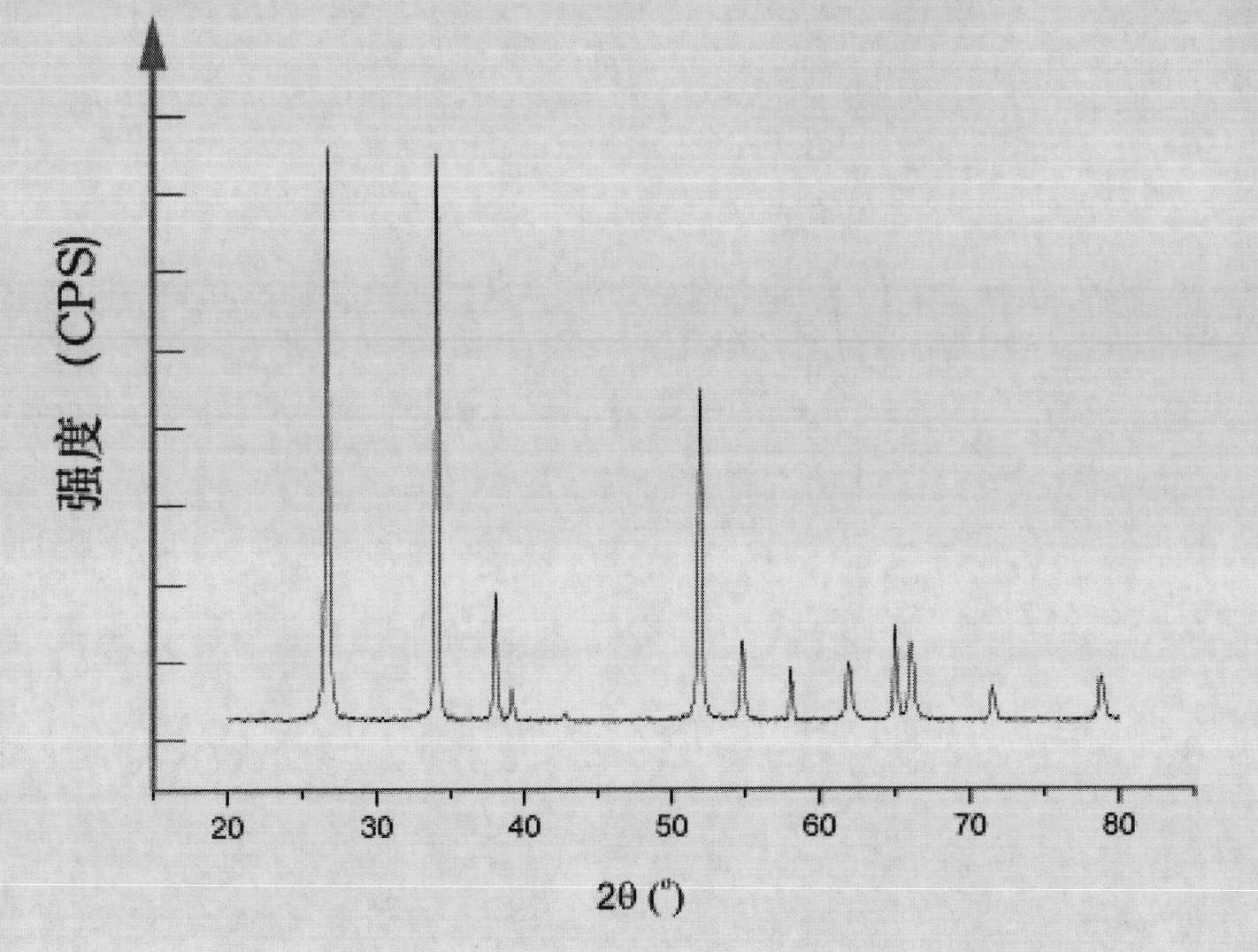

[0031] The results o...

Embodiment 2

[0033] A. prepare the tin chloride solution of 0.15mol / L with deionized water;

[0034] B. Sodium hydroxide is dissolved in deionized water to prepare an alkaline solution of 6mol / L;

[0035] C. Under stirring, slowly add the alkali solution prepared in step B into the tin chloride solution prepared in step A until the molar ratio of tin ions and hydroxide ions in the solution is 1:10, and then press the mixed solution volume Weigh an equal volume of absolute ethanol and mix it with the reaction solution, and disperse it with magnetic stirring for 5 minutes; transfer the dispersed reaction solution to a hydrothermal kettle, raise the temperature to 200°C, react at constant temperature for 40 hours, and cool naturally to room temperature. The product was filtered, washed with deionized water for 5 times, and then washed with absolute ethanol for 5 times, and then dried naturally to obtain a one-dimensional tin oxide nanomaterial with good crystallinity.

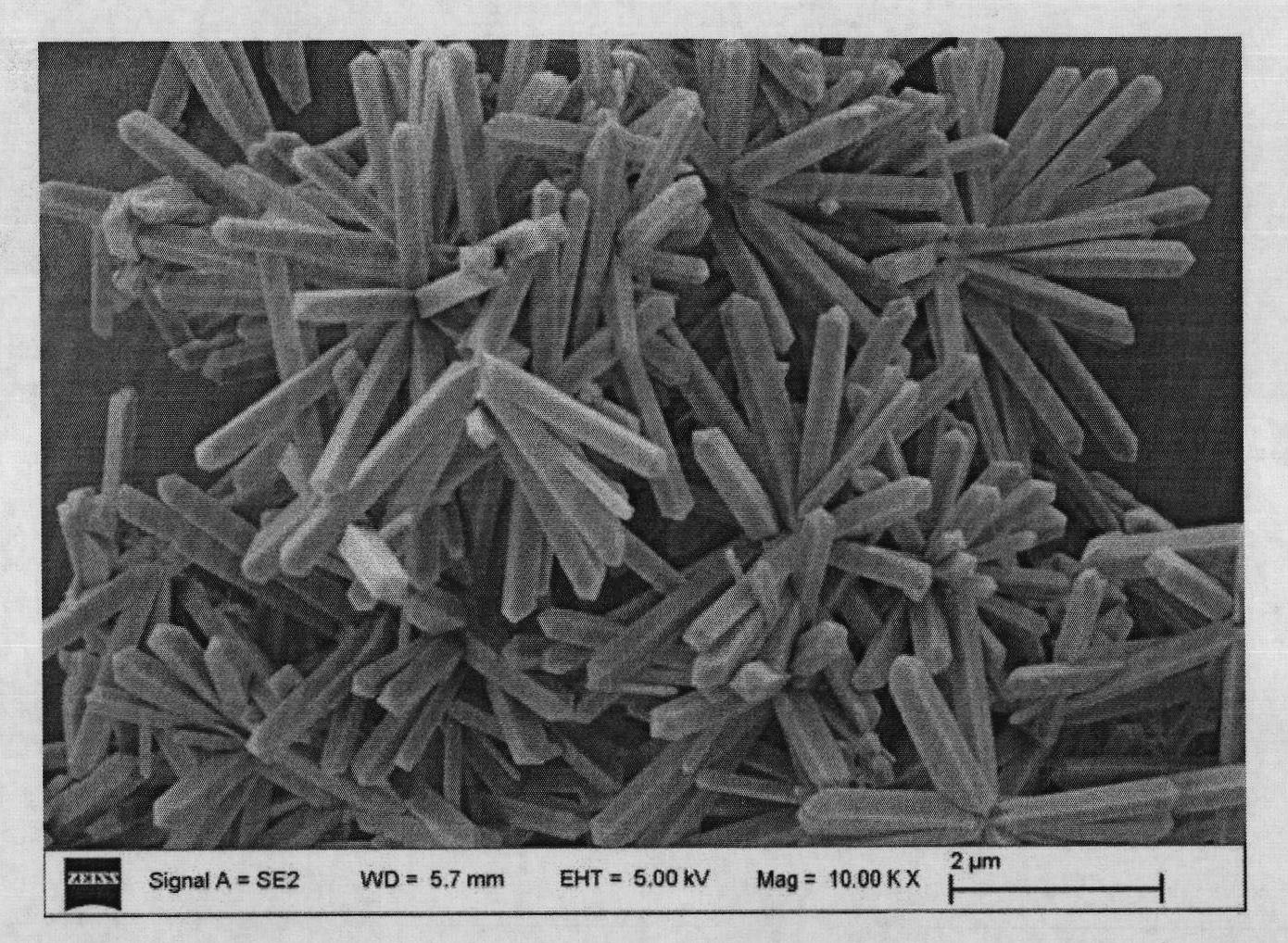

[0036] Scanning elect...

Embodiment 3

[0038] A. prepare the tin chloride solution of 0.3mol / L with deionized water;

[0039] B. Potassium hydroxide is dissolved in the deionized water preparation 4mol / L alkaline solution;

[0040]C. Under stirring, slowly add the alkali solution prepared in step B into the tin chloride solution prepared in step A until the molar ratio of tin ions and hydroxide ions in the solution is 1:10, and then press the mixed solution volume Weigh an equal volume of absolute ethanol and mix it with the reaction solution, and disperse it with magnetic stirring for 5 minutes; transfer the dispersed reaction solution to a hydrothermal kettle, raise the temperature to 220°C, react at a constant temperature for 24 hours, and cool naturally to room temperature. The product is filtered, washed with deionized water for 3 to 5 times, washed with absolute ethanol for 5 times, and then dried naturally to obtain a one-dimensional tin oxide nanometer material with good crystallinity.

[0041] Scanning el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com