Preparation method and application of graphene/tin oxide nano composite material

A nanocomposite material and graphene technology, which is applied in the field of preparation of graphene/tin oxide nanocomposite materials, can solve the problems of poor experimental reproducibility, cumbersome operation, difficult operation, etc., and achieve the effect of high sensitivity and easy process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 (1g per serving)

[0018] The preparation method of graphene / tin oxide nanocomposite material, its step is:

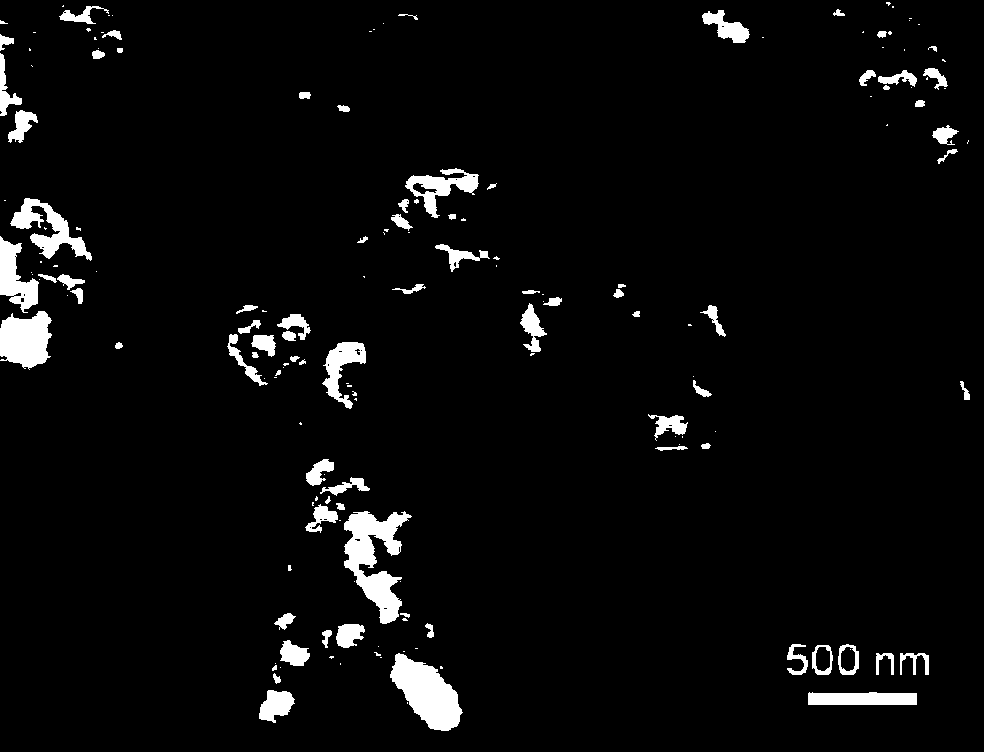

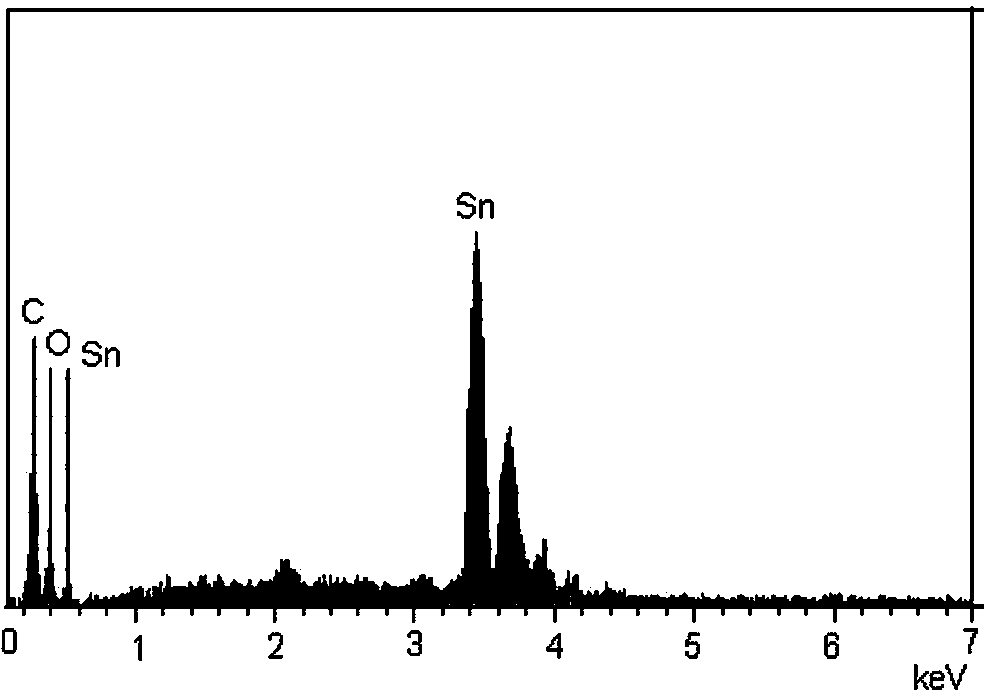

[0019] (1) Dissolve 2.5g of tin tetrachloride in 50mL of methanol, and then add 0.001g of graphene oxide with ultrasonic assistance to dissolve it fully; after ultrasonication for 30min, add 0.055g of hexadecyltrimethylammonium bromide, fully Mix; adjust the solution to pH 9 with ammonia water, and continue to sonicate for 45 minutes;

[0020] (2) Put the mixed solution obtained in step (1) into the reactor, and react at a constant temperature of 145°C for 18 hours; after the reactor is cooled to room temperature, take out the reactant, and after centrifugation, washing and drying, the graphene / oxidized tin nanocomposites.

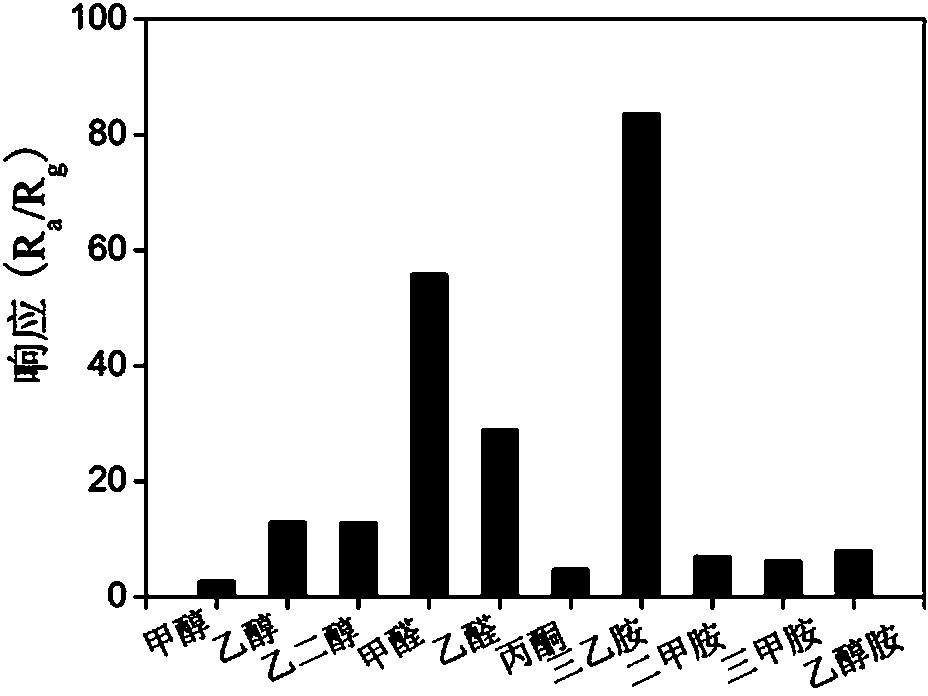

[0021] The application of the gas sensor prepared by the graphene / tin oxide nanocomposite material in the detection of triethylamine.

Embodiment 2

[0022] Example 2 (1g per serving)

[0023] The preparation method of graphene / tin oxide nanocomposite material, its step is:

[0024] (1) Dissolve 2g of tin dichloride in 40mL of methanol, and then add 0.0007g of graphene oxide with ultrasonic assistance to dissolve it fully; after 40min of ultrasonication, add 0.06g of cetyltrimethylammonium bromide and mix well ; Adjust the solution to pH 9 with ammonia water, and continue to sonicate for 40 minutes;

[0025] (2) Put the mixed solution obtained in step (1) into the reactor, and react at a constant temperature of 140°C for 19 hours; after the reactor was cooled to room temperature, the reactant was taken out, and after centrifugation, washing and drying, the graphene / oxidized tin nanocomposites.

Embodiment 3

[0026] Example 3 (1g per serving)

[0027] The preparation method of graphene / tin oxide nanocomposite material, its step is:

[0028] (1) Dissolve 2.2g of tin tetrachloride in 44mL of methanol, and then add 0.0005g of graphene oxide with ultrasonic assistance to dissolve it fully; after ultrasonication for 45min, add 0.05g of hexadecyltrimethylammonium bromide, fully Mix; adjust the solution to pH 9 with ammonia water, and continue to sonicate for 30 minutes;

[0029] (2) Put the mixed solution obtained in step (1) into the reactor, and react at a constant temperature of 150°C for 20 hours; after the reactor is cooled to room temperature, take out the reactant, and after centrifugation, washing and drying, the graphene / oxidized tin nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com