Antimony-doped tin oxide cladding titanium dioxide composite conductive material and preparation method

A titanium dioxide, composite conductive technology, applied in the directions of oxide conductors, conductive layers on insulating carriers, metal/alloy conductors, etc., can solve problems such as lack, and achieve the effects of short synthesis cycle, light color, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

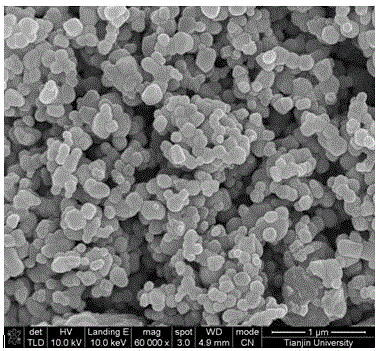

Embodiment 1

[0012] Add 2.000g of titanium dioxide to 150ml of deionized water and ultrasonically disperse for 2 hours to prepare suspension 1; take 20mL of hydrochloric acid solution with a mass concentration of 18%, and add 4.383g of crystalline tin tetrachloride under constant stirring, and wait until it is completely dissolved Then add 0.143g of antimony chloride to obtain solution 2; take 2.000g of sodium hydroxide and add 50mL of deionized water to prepare clear solution 3; while stirring, add solution 2 and solution 3 dropwise to suspension 1 at the same time, after the reaction is completed Continue to stir for 0.5h, after aging for 5h, centrifugally wash with deionized water, wash until there is no chloride ion in the solution, dry at 115°C for 5h, grind the dried powder and calcinate at 500°C for 2h to obtain antimony-doped oxide Tin-coated titanium dioxide composite conductive powder material. The conductive powder is composed of an antimony-doped tin oxide coating layer with ...

Embodiment 2

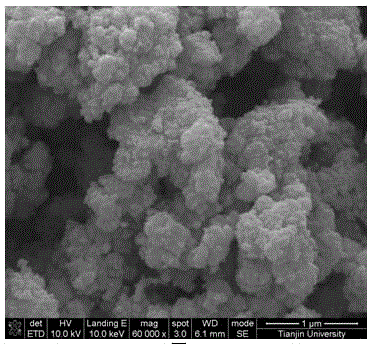

[0014] Add 1.500g of titanium dioxide to 150ml of deionized water and ultrasonically disperse for 2 hours to prepare suspension 1; take 20mL of hydrochloric acid solution with a mass concentration of 18%, and add 4.602g of crystalline tin tetrachloride under constant stirring, and wait until it is completely dissolved Then add 0.150g of antimony chloride to obtain solution 2; add 4.000g of sodium hydroxide to 50mL of deionized water to prepare a clear solution 3; Continue to stir for 0.5h after the reaction is completed, centrifuge and wash after aging for 5h, dry at 80°C for 10h, grind the dried powder and calcinate at 500°C for 2h to obtain antimony-doped tin oxide-coated titanium dioxide composite conductive powder material .

Embodiment 3

[0016] The experimental procedure of this example is the same as that of Example 1, except that the heat treatment temperature is changed from 500° C. to 700° C. to obtain an antimony-doped tin oxide-coated titanium dioxide composite conductive powder material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com