Process for synthesizing spinel zine stannate nano rod

A technology of spar zinc stannate and a synthesis method, applied in the directions of zinc compounds, tin compounds, nanotechnology, etc., can solve the problems of difficulty in nanoparticles, high temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

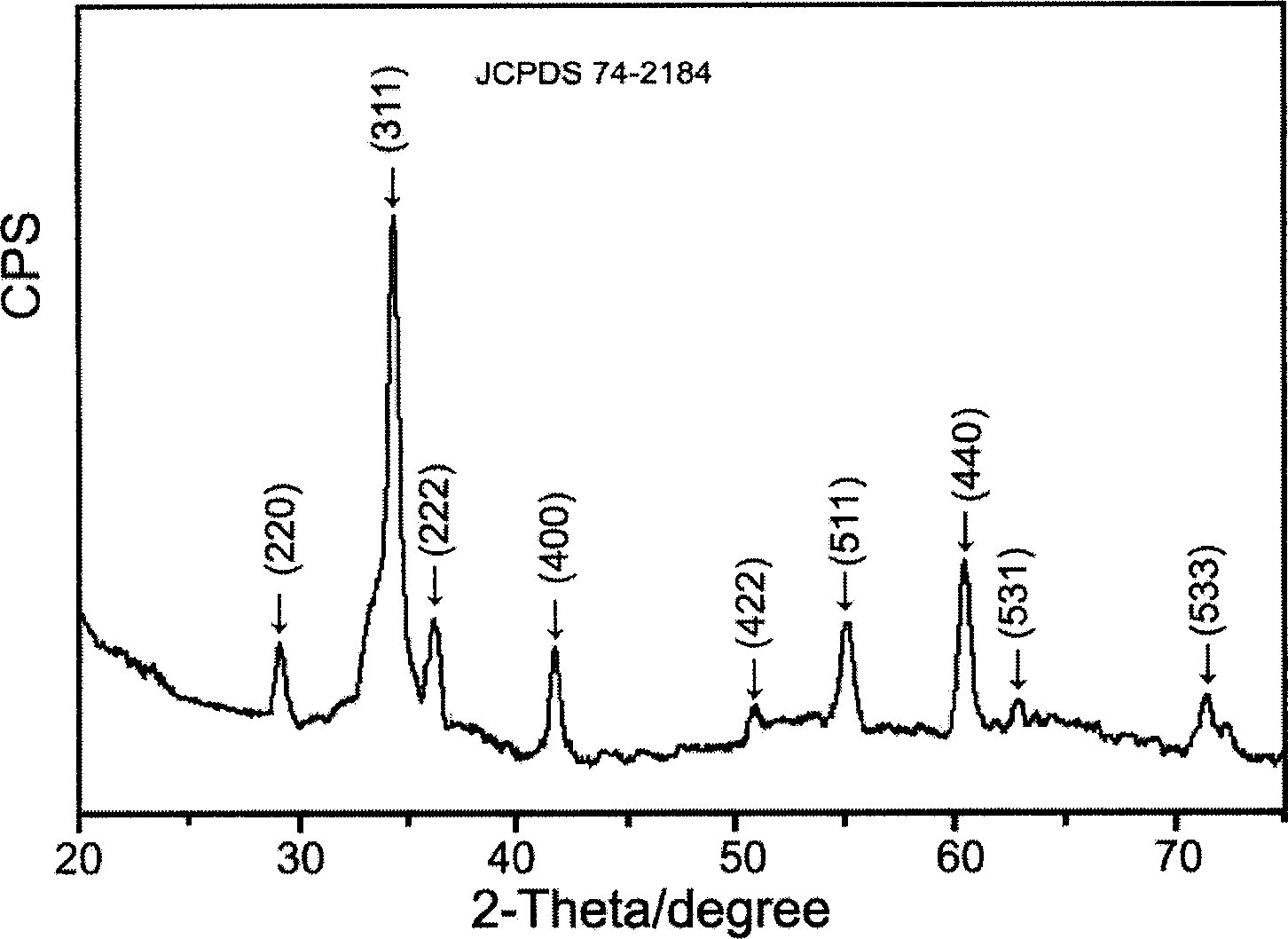

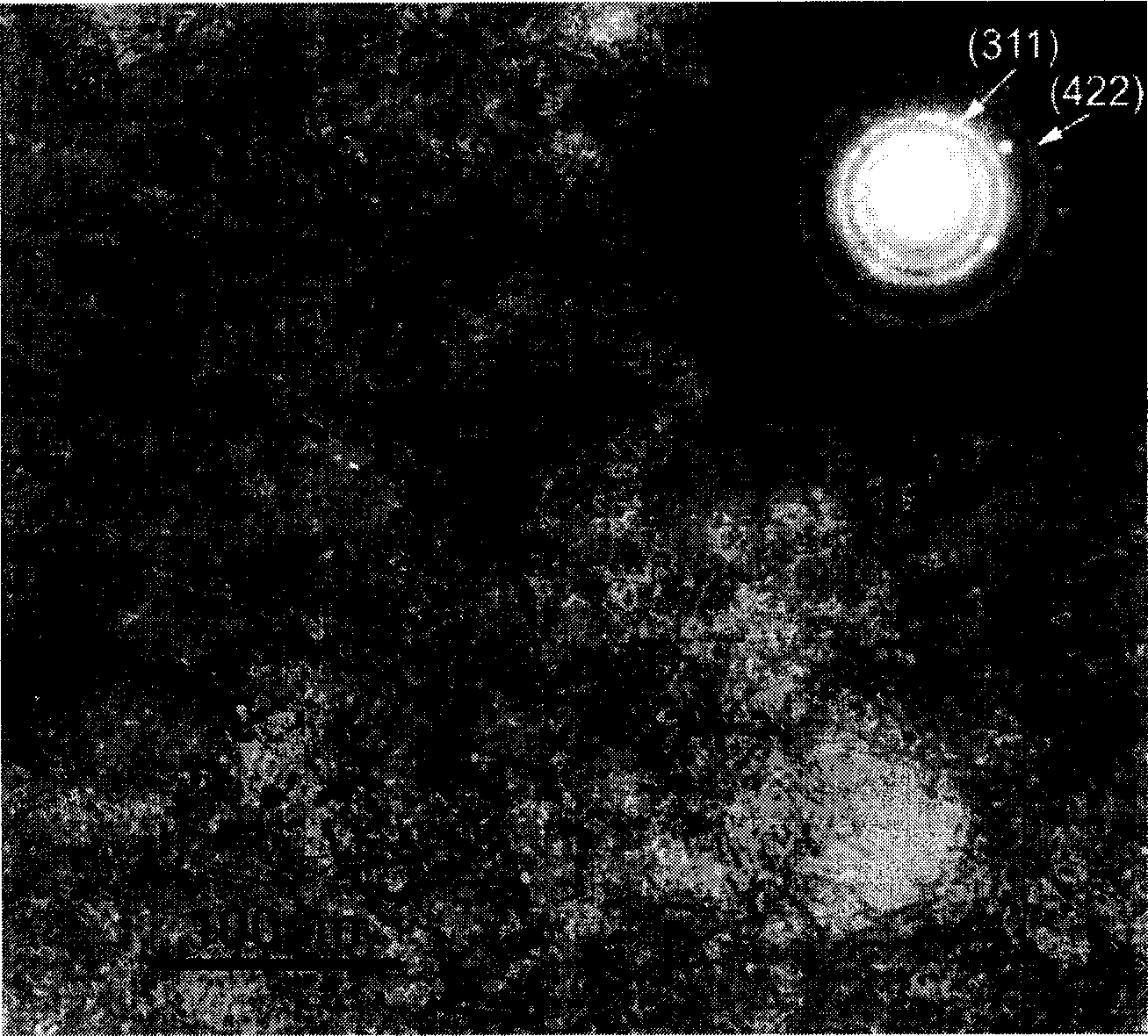

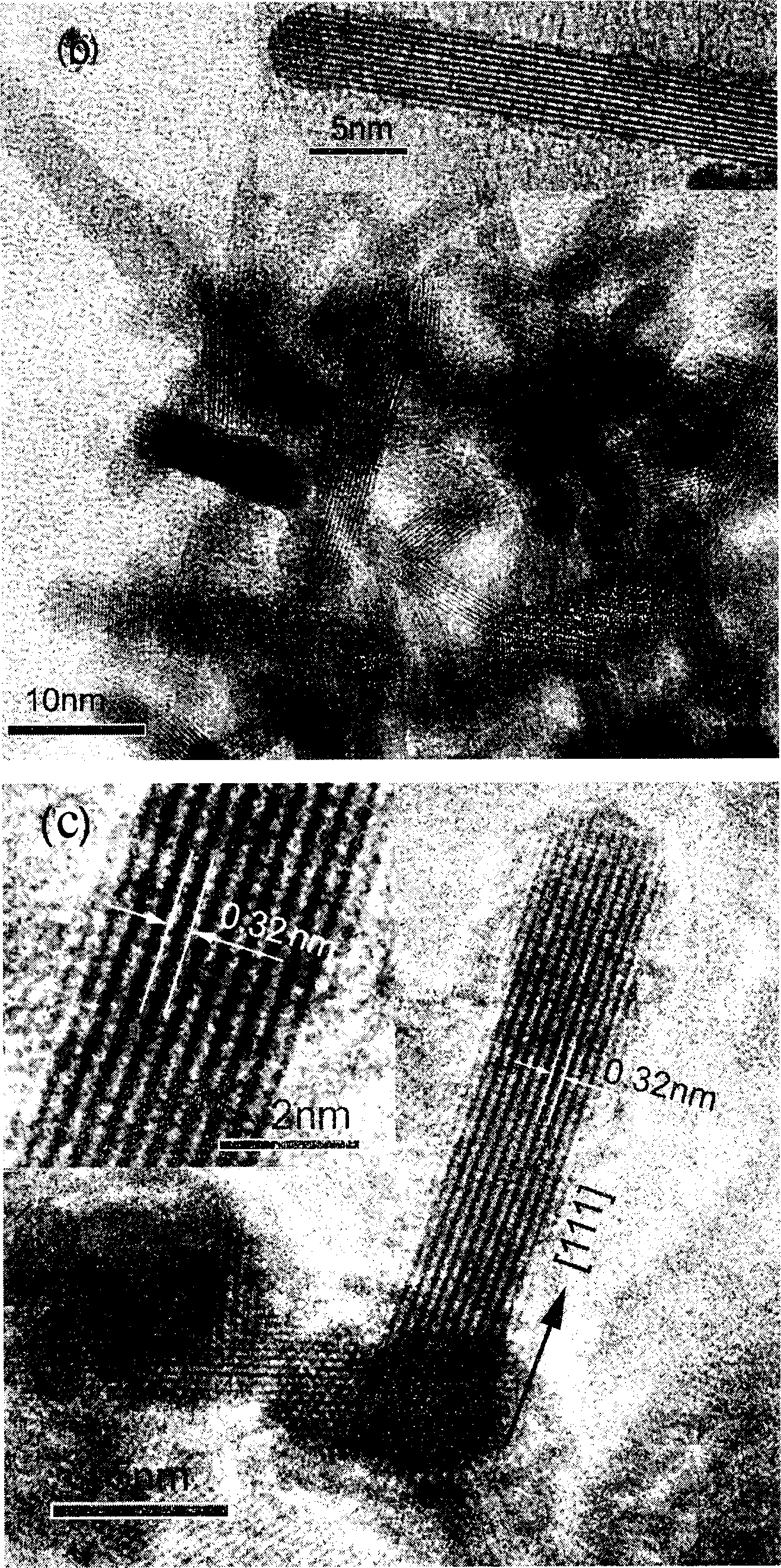

[0012] 1.7408 grams of zinc chloride (ZnCl 2 , 0.0128 moles) and 2.2400 grams of tin chloride (SnCl 4 ·5H 2 O, 0.0064 mole) is put into 160 milliliters of deionized water, then adds 2.5600 grams of hydrazine hydrate (N 2 h 4 ·H 2 (2, 0.0512 moles), after stirring for 10 minutes, put the above-mentioned prepared solution into the polytetrafluoroethylene lining of the autoclave, and the lining volume is 200 milliliters, that is, the filling degree is 80%. The solution is treated at 250° C. for 24 hours, and the treated solution is centrifuged and dried to obtain ZTO nanorods of 2 to 4 nanometers. figure 1 is the XRD pattern of ZTO nanorods, and Zn 2 SnO 4 The standard card (JCPDS 74-2184) matches exactly. figure 2 is the TEM photo of ZTO nanorods, from figure 2 It can be seen that the obtained product is a single crystal ZTO nanorod of 2-4 nanometers.

Embodiment 2

[0014] 1.7408 grams of zinc chloride (ZnCl 2 , 0.0128 moles) and 2.2400 grams of tin chloride (SnCl 4 ·5H 2 O, 0.0064 mole) is put into 160 milliliters of deionized water, then adds 2.5600 grams of hydrazine hydrate (N 2 h 4 ·H 2 (2, 0.0512 moles), after stirring for 10 minutes, put the above-mentioned prepared solution into the polytetrafluoroethylene lining of the autoclave, and the lining volume is 200 milliliters, that is, the filling degree is 80%. The solution is treated at 300° C. for 24 hours, and the treated solution is centrifuged and dried to obtain ZTO nanorods of 3 to 5 nanometers. It can be seen that as the hydrothermal temperature rises, the crystal grows slightly. But when the hydrothermal temperature is lower than 250°C, the crystallization of the product is not good.

Embodiment 3

[0016] 1.7408 grams of zinc chloride (ZnCl 2 , 0.0128 moles) and 2.2400 grams of tin chloride (SnCl 4 ·5H 2 O, 0.0064 mole) is put into 160 milliliters of deionized waters, then adds 3.8400 grams of hydrazine hydrate (N 2 h 4 ·H 2 (2, 0.0768 moles), after stirring for 10 minutes, put the above-mentioned prepared solution into the polytetrafluoroethylene lining of the autoclave, and the lining volume is 200 milliliters, that is, the filling degree is 80%. The solution was treated at 250°C for 24 hours, and the treated solution was centrifuged and dried to obtain ZTO nanorods of 2 to 4 nanometers. The results were consistent with Example 1, indicating that the concentration of hydrazine hydrate had little effect on the product within a certain range. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com