Preparation method of tin sulfide-carbon nanotube composite electrode material

A carbon nanotube composite and tin disulfide technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome preparation process and achieve the effects of simple preparation method, regular shape and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, adding 30 mg of carboxylated multi-walled carbon nanotubes to 60 mL of absolute ethanol, and ultrasonically dispersed for 3 hours to obtain dispersion A;

[0036] Step 2, weigh 0.53g of tin tetrachloride pentahydrate and add it to the obtained dispersion A, stir for 20min, then add 0.45g of thioacetamide under stirring, and stir for 30min to obtain solution B;

[0037] Step 3, the obtained solution B was transferred to a reaction kettle lined with polytetrafluoroethylene, kept at 160°C for 12 hours, and naturally cooled to room temperature after the reaction to obtain a dark green precipitate;

[0038]Step 4, collect the dark green precipitate and successively wash it with deionized water and absolute ethanol by centrifugation, and place it in a vacuum drying oven at 60°C for 12 hours to obtain a tin disulfide-carbon nanotube composite electrode material for lithium ion batteries.

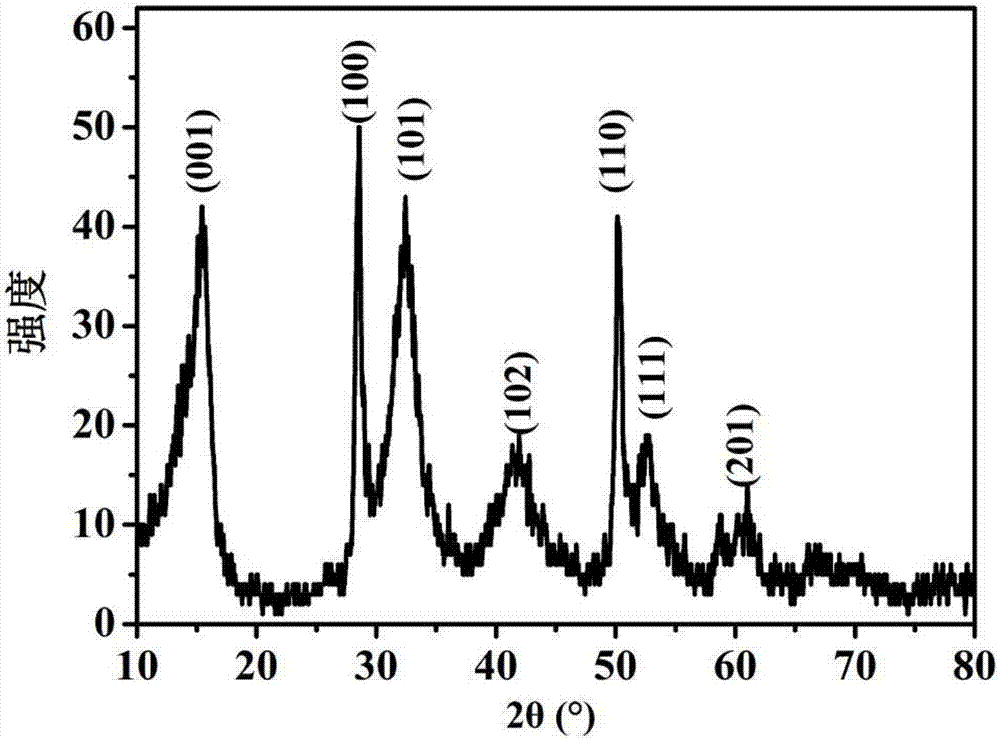

[0039] Such as figure 1 Shown, be the XRD collection of illustrative plates of ...

Embodiment 2

[0041] Step 1, adding 90 mg of carboxylated multi-walled carbon nanotubes to 60 mL of absolute ethanol, and ultrasonically dispersed for 2.5 hours to obtain dispersion A;

[0042] Step 2, weigh 0.53g of tin tetrachloride pentahydrate and add it to the obtained dispersion A, stir for 10min, then add 0.45g of thioacetamide under stirring, and stir for 35min to obtain solution B;

[0043] Step 3, transfer the obtained solution to a reaction kettle lined with polytetrafluoroethylene, heat it with conventional water at 180°C for 16 hours, and cool it naturally to room temperature after the reaction to obtain a dark green precipitate;

[0044] Step 4, collect the dark green precipitate, wash it with deionized water and absolute ethanol successively, and dry it in a vacuum oven at 80° C. for 8 hours to obtain a tin disulfide-carbon nanotube composite electrode material for lithium ion batteries.

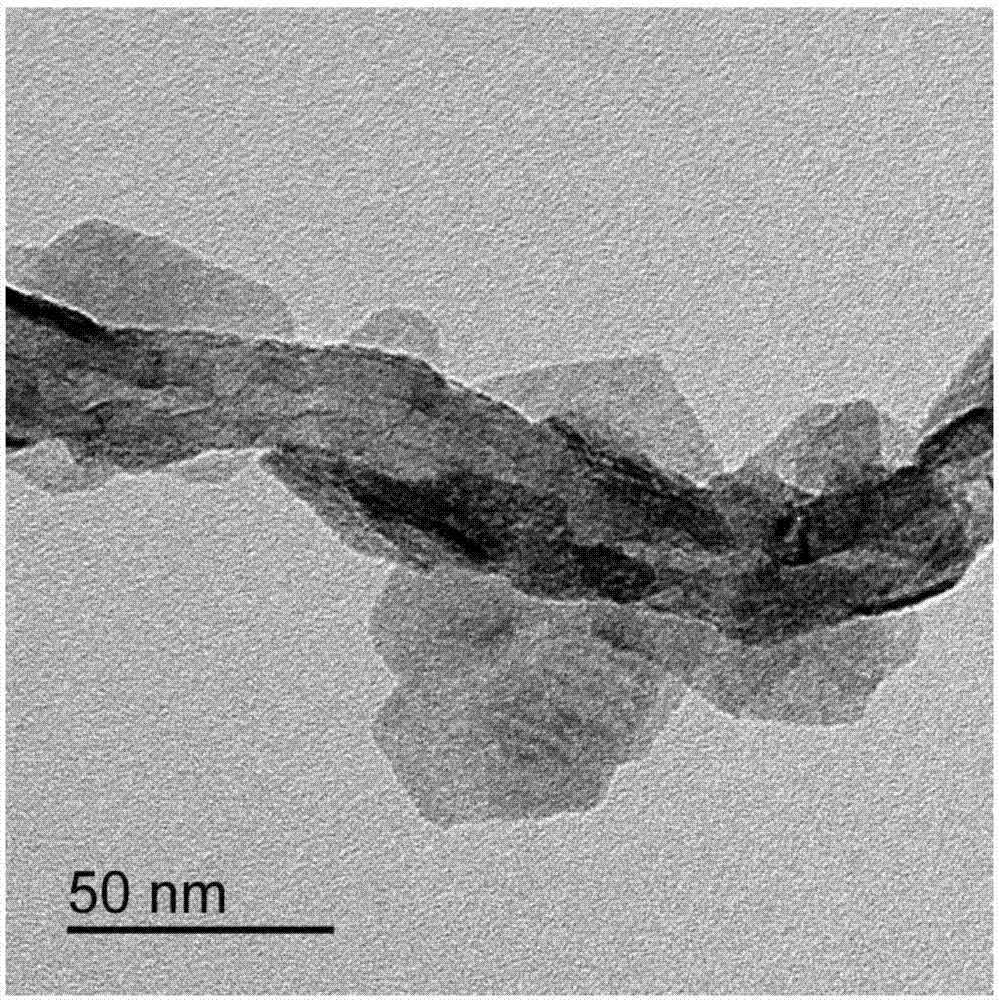

[0045] Such as figure 2 Shown is the transmission electron micrograph of the tin disu...

Embodiment 3

[0047] Step 1, adding 60 mg of carboxylated multi-walled carbon nanotubes to 60 mL of absolute ethanol, and ultrasonically dispersed for 3.5 hours to obtain dispersion A;

[0048] Step 2, weigh 0.53g of tin tetrachloride pentahydrate and add it to the obtained dispersion A, stir for 20min, then add 0.45g of thioacetamide under stirring, and stir for 30min to obtain solution B;

[0049] Step 3, the obtained solution B was transferred to a reaction kettle lined with polytetrafluoroethylene, kept at 180°C for 12 hours, and naturally cooled to room temperature after the reaction, to obtain a dark green precipitate;

[0050] Step 4, collect the dark green precipitate and successively wash it with deionized water and absolute ethanol, and dry it in a vacuum oven at 70°C for 10 hours to obtain a tin disulfide-carbon nanotube composite electrode material for lithium ion batteries.

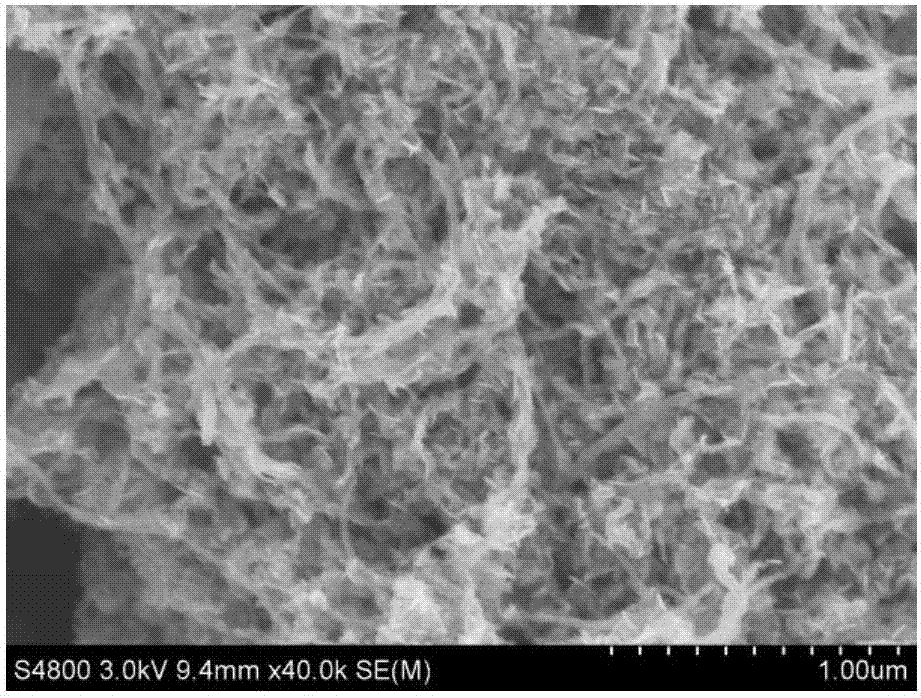

[0051] Such as Figure 3-4 as shown, Figure 3-4 For the scanning electron micrograph of the prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com