Method for preparing graphene-SnIn4S8 nano composite photocatalyst at low temperature by adopting coprecipitation method

A -snin4s8, nanocomposite technology, applied in the field of photocatalyst preparation, can solve the problems of harming the environment, easy dissolution, expensive metal materials, etc., and achieve the effects of short preparation time, large specific surface area, high stability and regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

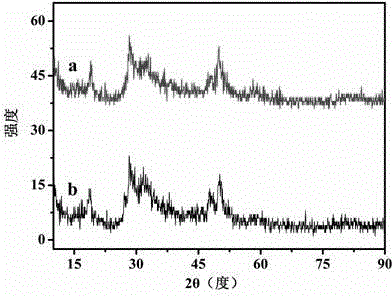

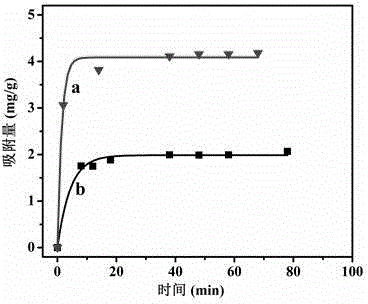

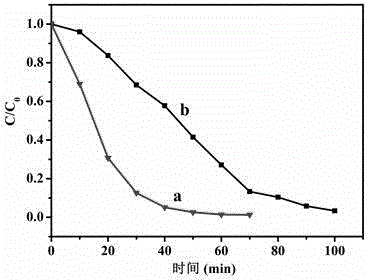

[0023] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then reduced with 80% hydrazine hydrate to obtain reduced graphene oxide.

[0024] (2) Add 2.0 mmol of tin chloride, 8.0 mmol of indium chloride, and 12 mmol of thioacetamide into 50 mL of ethanol solution and stir until the solution is transparent, then add 0.2 mmol of graphene, and then perform ultrasonication for 30 min.

[0025] (3) Transfer the solution to a 100 mL three-necked flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 55o C, the water bath time is 4 hours.

[0026] (4) The sample after the water bath was suction filtered and washed three times with deionized water and ethanol, and the obtained sample was at 80 o C for 12 hours. Then take it out, let it cool naturally, and grind it. The resulting product is RGO-SnIn 4 S 8 Nanocomposite photocatalysts.

Embodiment 2

[0028] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then reduced with 80% hydrazine hydrate to obtain reduced graphene oxide.

[0029] (2) Add 2.0 mmol of tin chloride, 8.0 mmol of indium chloride, and 24 mmol of thioacetamide into 50 mL of ethylene glycol solution and stir until the solution is transparent, then add 0.1 mmol of graphene, and then perform ultrasonication for 30 min.

[0030] (3) Transfer the solution to a 100 mL three-neck flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 95 o C, the water bath time is 10 hours.

[0031] (4) The sample after the water bath was suction filtered and washed three times with deionized water and ethanol, and the obtained sample was at 80 o C for 12 hours. Then take it out, let it cool naturally, and grind it. The resulting product is RGO-SnIn 4 S 8 Nanocomposite photocatalysts.

Embodiment 3

[0033] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then reduced with 80% hydrazine hydrate to obtain reduced graphene oxide.

[0034] (2) Add 2.0 mmol of tin chloride, 8.0 mmol of indium chloride, and 12 mmol of thioacetamide into 50 mL of butanol solution and stir until the solution is transparent, then add 0.06 mmol of graphene, and then perform ultrasonication for 30 min.

[0035] (3) Transfer the solution to a 100 mL three-necked flask, add a condensing reflux device, and stir at an appropriate rate, and the temperature of the water bath is 55 o C, the water bath time is 10 hours.

[0036] (4) The sample after the water bath was suction filtered and washed three times with deionized water and ethanol, and the obtained sample was at 80 o C for 12 hours. Then take it out, let it cool naturally, and grind it. The resulting product is RGO-SnIn 4 S 8 Nanocomposite photocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com