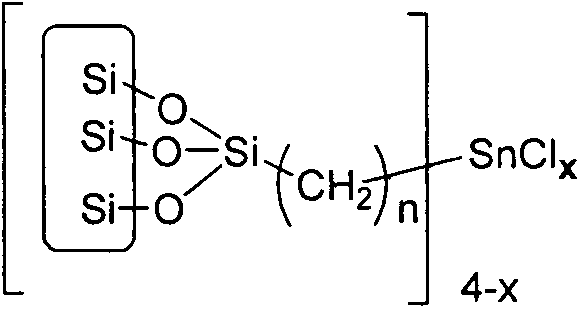

Silicon oxide-immobilized organic tin catalyst for transesterification of dimethyl carbonate and phenol ester, and preparation method thereof

A technology of dimethyl carbonate and silicon oxide is applied in the field of silicon oxide immobilized organotin catalyst and preparation, which can solve problems such as complicated preparation process, and achieve the effect of simple preparation method and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

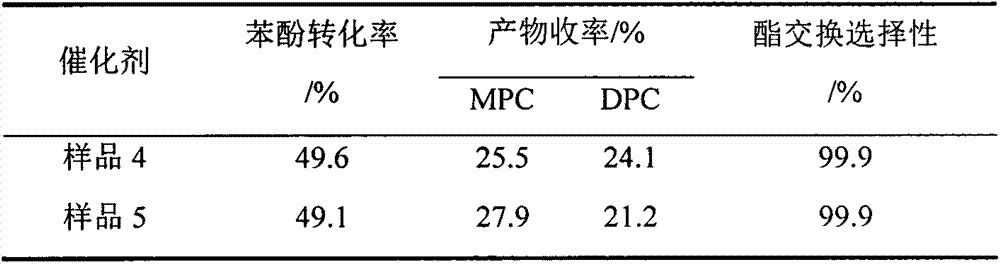

Examples

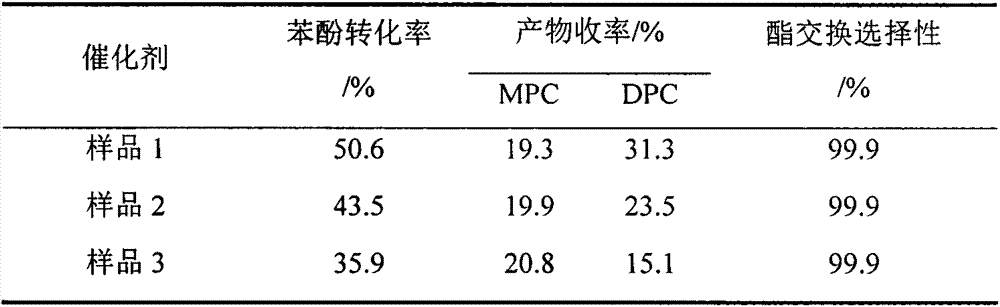

Embodiment 1

[0018] Add 6g of 3-chloropropylethoxysilane, 2g of magnesium powder and a small amount of iodine to 60mL of diethyl ether, heat to reflux for 3h, then add 6.5g of anhydrous tin tetrachloride, heat at reflux at 130°C for 3h to obtain propyl tri Silane reagent solution of tin chloride; add 25g ethyl orthosilicate to the silane reagent solution of propyltin trichloride, stir and add the solution to 150mL of 20% hydrochloric acid, stir for 2h, filter, wash, 120°C Vacuum drying was carried out to obtain a silica-immobilized organotin catalyst sample 1 whose active component was propyltin trichloride, and the tin loading was 23.5% as measured by an inductively coupled plasma atomic emission spectrometer.

Embodiment 2

[0020] Add 9g of 3-chlorobutylethoxysilane, 3g of magnesium powder and a small amount of iodine to 80mL of diethyl ether, heat to reflux for 2h, then add 4.6g of anhydrous tin tetrachloride, and heat at 130°C for 4h to obtain dibutyl The silane reagent solution of tin dichloride; add 50g of isopropyl silicate to the silane reagent solution of dibutyltin dichloride, after stirring, add the solution to 200mL of 18% ammonia water, stir for 1h, filter, wash, Dry at 120° C. to obtain a silica-immobilized organotin catalyst sample 2 whose active component is dibutyltin dichloride, and the tin loading is 12.8%.

Embodiment 3

[0022] Add 9g of 4-chlorobutylethoxysilane, 3g of magnesium powder and a small amount of iodine to 80mL of ether, heat to reflux for 2h, then add 4.6g of anhydrous tin tetrachloride, and heat at 130°C for 4h to obtain dibutyl The silane reagent solution of tin dichloride; add 10g of mesoporous silicon oxide to the silane reagent solution of dibutyltin dichloride, heat and reflux for 8h, filter, wash, and vacuum dry at 120°C to obtain the active component dibutyl Silicon oxide immobilized organotin catalyst sample 3 of tin dichloride, with a tin loading of 8.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com