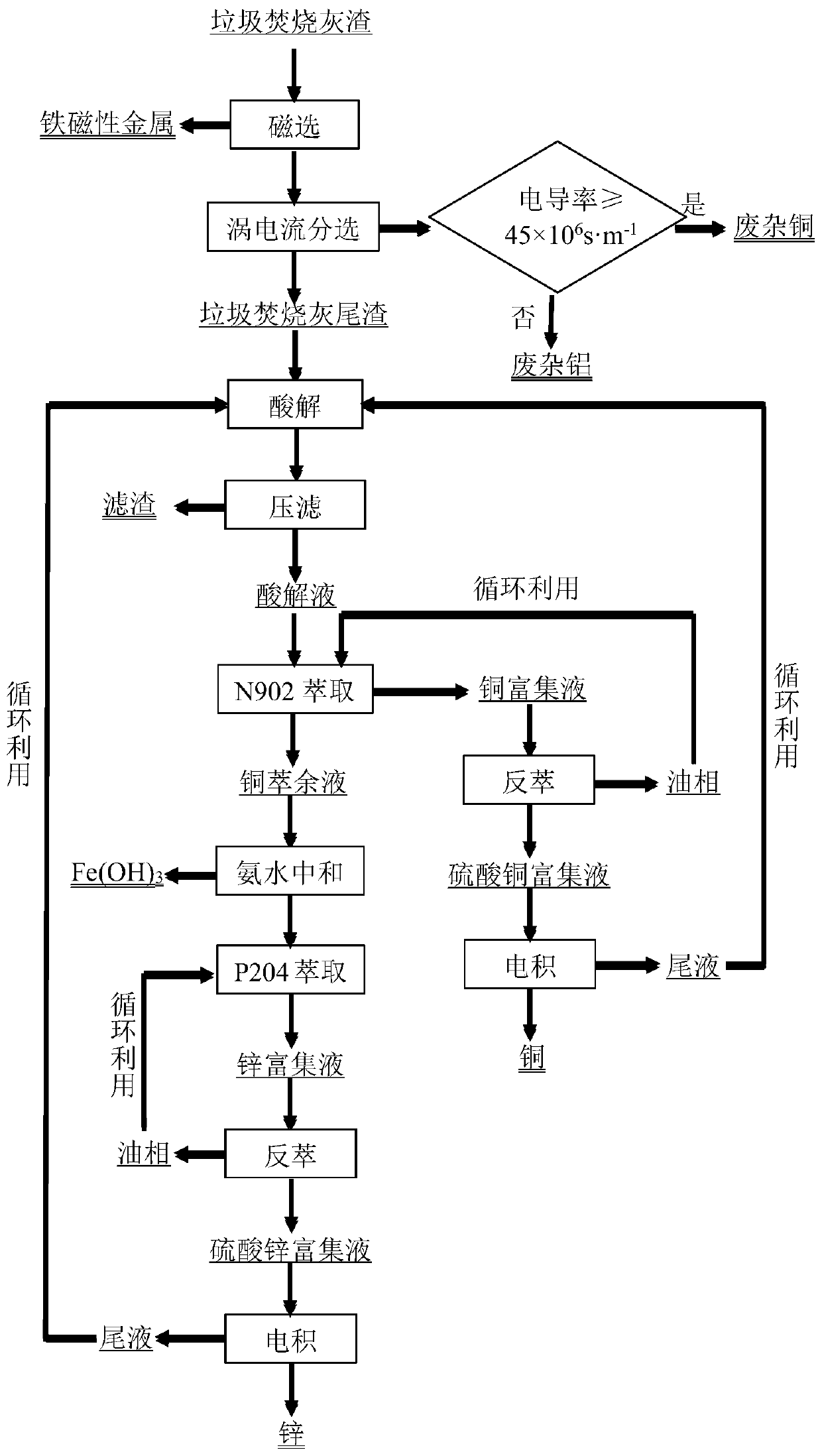

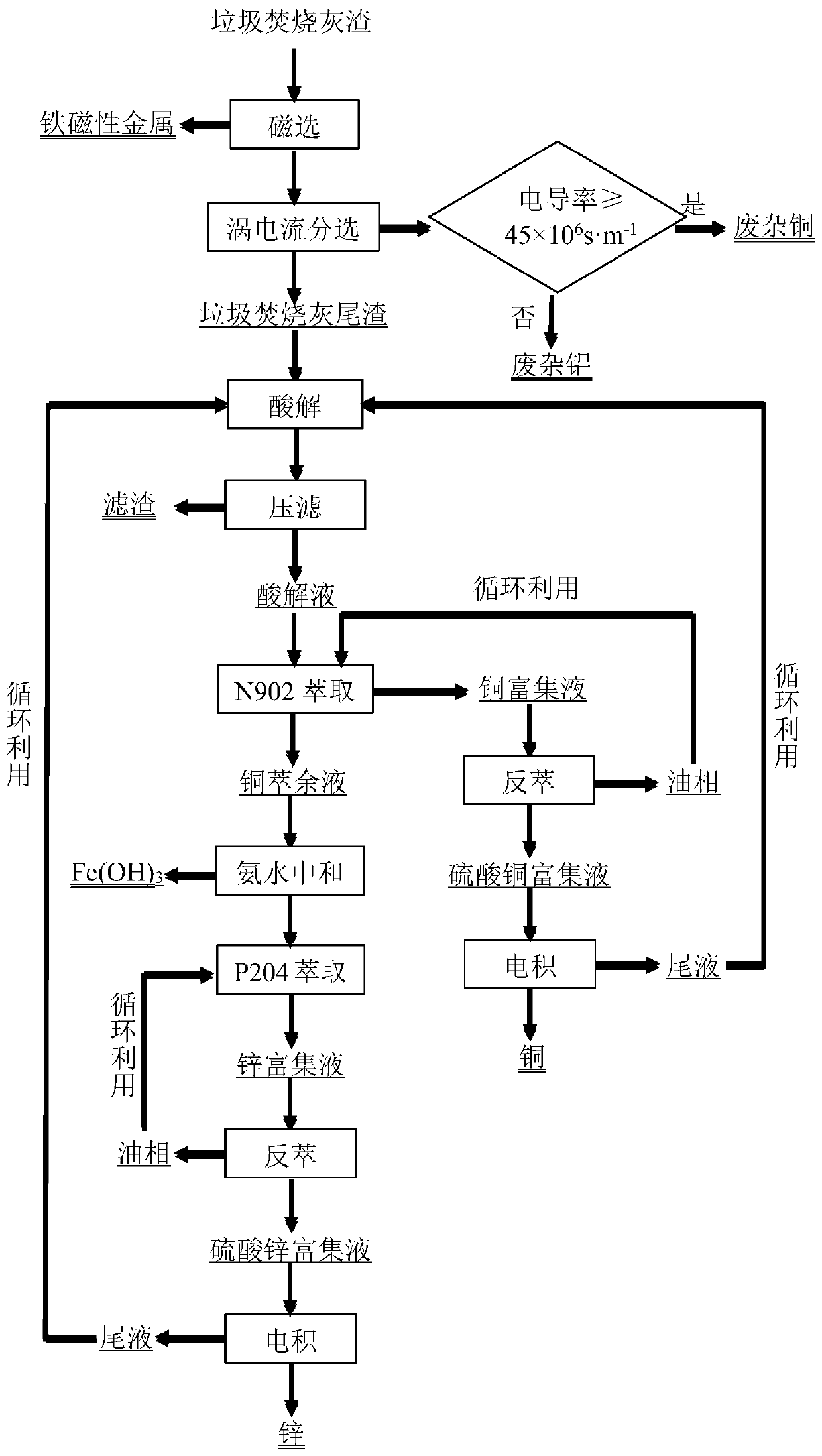

A method for extracting valuable metals from waste incineration ash

A technology for waste incineration ash and valuable metals, applied in chemical instruments and methods, process efficiency improvement, instruments and other directions, can solve the problems of heavy metal pollution, low extraction rate of valuable metals, etc., to achieve a short process, avoid heavy metal pollution, The effect of a wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The magnetic separator is set to export ferromagnetic metals with a relative magnetic permeability > 5, and to export non-ferrous ash with a relative magnetic permeability ≤ 5. The waste incineration ash is subjected to magnetic separation to obtain ferromagnetic metal and non-ferrous ash.

[0038] The set conductivity of the eddy current separator is ≥45×10 6 s m -1 For scrap copper export, 45×10 3 s m -1 ≤Conductivity6 s m -1 For the export of waste miscellaneous aluminum, the electrical conductivity is less than 45×10 3 s m -1 for the export of waste incineration ash tailings. The non-iron ash is sorted by eddy current to obtain waste miscellaneous copper, waste miscellaneous aluminum and waste incineration ash tailings.

[0039]The waste incineration ash tailings were dissolved with 1mol / L sulfuric acid, the liquid-solid mass ratio was 4:1, the acid hydrolysis temperature was 20°C, and the acid hydrolysis time was 4 hours, followed by 0.2MPa pressure filtrati...

Embodiment 2

[0041] The magnetic separator is set to export ferromagnetic metals with a relative magnetic permeability > 5, and to export non-ferrous ash with a relative magnetic permeability ≤ 5. The waste incineration ash is subjected to magnetic separation to obtain ferromagnetic metal and non-ferrous ash.

[0042] The set conductivity of the eddy current separator is ≥45×10 6 s m -1 For scrap copper export, 45×10 3 s m -1 ≤Conductivity6 s m -1 For the export of waste miscellaneous aluminum, the electrical conductivity is less than 45×10 3 s m -1 for the export of waste incineration ash tailings. The non-iron ash is sorted by eddy current to obtain waste miscellaneous copper, waste miscellaneous aluminum and waste incineration ash tailings.

[0043] The waste incineration ash tailings were dissolved with 1.5mol / L sulfuric acid, the liquid-solid mass ratio was 4.5:1, the acidolysis temperature was 25°C, and the acidolysis time was 3.8h, followed by 0.2MPa pressure filtration to ob...

Embodiment 3

[0045] The magnetic separator is set to export ferromagnetic metals with a relative magnetic permeability > 5, and to export non-ferrous ash with a relative magnetic permeability ≤ 5. The waste incineration ash is subjected to magnetic separation to obtain ferromagnetic metal and non-ferrous ash. The set conductivity of the eddy current separator is ≥45×10 6 s m -1 For scrap copper export, 45×10 3 s m -1 ≤Conductivity6 s m -1 For the export of waste miscellaneous aluminum, the electrical conductivity is less than 45×10 3 s m -1 for the export of waste incineration ash tailings. The non-iron ash is sorted by eddy current to obtain waste miscellaneous copper, waste miscellaneous aluminum and waste incineration ash tailings.

[0046] The waste incineration ash tailings were dissolved with 2mol / L sulfuric acid, the liquid-solid mass ratio was 5:1, the acidolysis temperature was 30°C, and the acidolysis time was 3.6h, followed by 0.3MPa pressure filtration to obtain the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com