A mixed amine extractant for the separation of molybdenum and vanadium and a method for separating and recovering molybdenum and vanadium from spent catalysts

A waste catalyst, separation and recovery technology, applied in the direction of improving process efficiency, etc., can solve the problems that the separation of vanadium and molybdenum cannot be realized, and the separation coefficient is not much different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

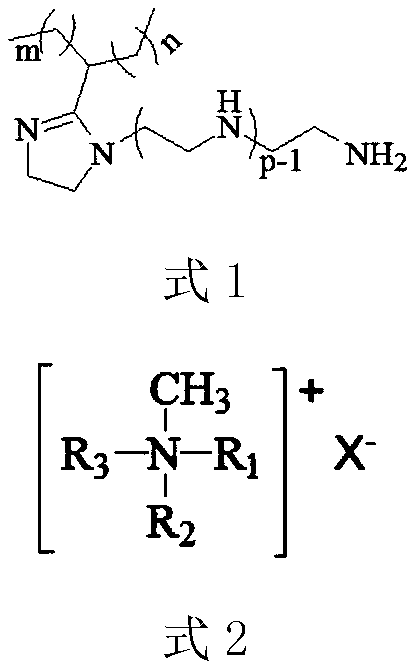

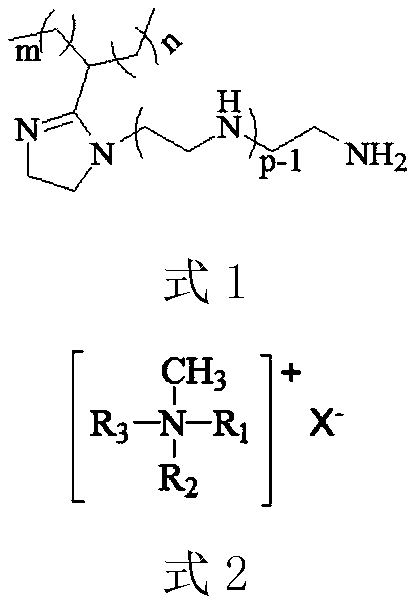

[0049] Accurately measure the mixed amine extractant with a volume fraction of 16% (the volume ratio of formula 1 and formula 2 is 1:1) + 14% isooctyl alcohol + sulfonated kerosene, mix well, and dilute hydrochloric acid and sodium chloride After pretreatment of the mixed solution, for Mo101.00g / L, V 2 o 5 9.87g / L of vanadium and molybdenum leachate was extracted, compared with O / A=1:2, the oscillation frequency was 190r / min, oscillated for 10min at room temperature, and solid sodium hydroxide was added to change the pH of the leachate, the extraction rate and separation of molybdenum and vanadium The coefficients are shown in Table 1:

[0050] Table 1 Effect of equilibrium pH on extraction and separation of molybdenum and vanadium in leach solution

[0051] balance pH 7.52 8.73 9.63 10.51 11.72 13.01 Vanadium extraction rate / % 55.72 52.38 20.64 1.31 0.72 0.18 Molybdenum extraction rate / % 0.71 0.21 0.34 0.56 0.24 0.12 Separation coe...

Embodiment 2

[0054] Accurately measure a mixed amine extractant with a volume fraction of 15% (the volume ratio of formula 1 and formula 2 is 2:1) + 15% isooctyl alcohol + sulfonated kerosene, mix well, and mix with dilute hydrochloric acid and sodium chloride After solution pretreatment, for Mo 101.00g / L, V 2 o 5 9.87g / L of vanadium and molybdenum leachate was extracted, compared with O / A=1:2, the oscillation frequency was 190r / min, oscillated for 10min at room temperature, and solid sodium hydroxide was added to change the pH of the leachate, the extraction rate and separation of molybdenum and vanadium The coefficients are shown in Table 2:

[0055] Table 2 Effect of equilibrium pH on extraction and separation of molybdenum and vanadium in leach solution

[0056] balance pH 7.02 8.13 9.11 10.08 11.22 12.01 Vanadium extraction rate / % 58.36 56.31 23.46 4.13 2.27 1.08 Molybdenum extraction rate / % 6.17 4.13 2.54 1.76 0.89 0.42 Separation coeffici...

Embodiment 3

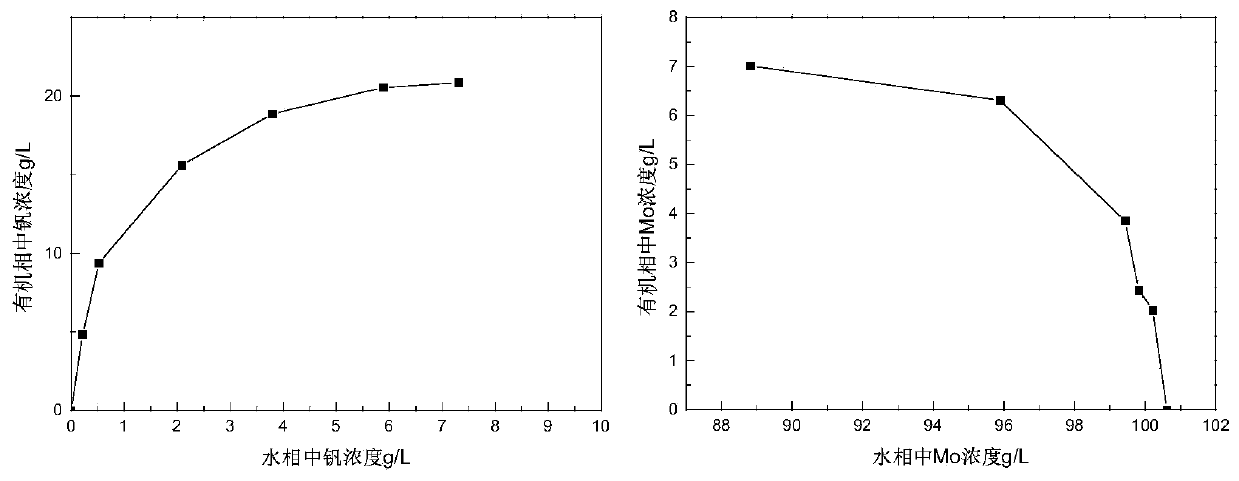

[0064] The composition of the organic phase is: 15% mixed extractant (the volume ratio of formula 1 and formula 2 is 2:1) + 12% isooctyl alcohol + 73% sulfonated kerosene, for Mo 101.00g / L, V 2 o 5 9.87g / L of vanadium-molybdenum leach solution was used for phase-distorted extraction, the oscillation frequency was 190r / min, and the oscillation frequency was 10min at room temperature. The pH of the feed solution was 9.12. The extraction isotherms of molybdenum and vanadium were as follows: figure 1 Shown:

[0065] From figure 1 It can be seen that as the ratio O / A decreases, the content of vanadium in the organic phase increases rapidly at first, and then tends to remain unchanged. At this time, the content of vanadium in the organic phase reaches saturation. It can be known that, when the extractant content is 15%, the saturation capacity of vanadium in the organic phase is 20.87g / L. In addition, according to the isotherm curve of Mo, it can be seen that the organic phase c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com