Treatment system and process suitable for outlet coke gas of dry quenching

A technology of treatment system and treatment process, which is applied in the field of waste gas treatment, can solve the problems of substandard purification effect, weak treatment process, incomplete export, purification and utilization process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The VOC S The preparation method of absorbent is as follows:

[0036] 1) Add ethanol into the beaker, and heat it to 30-60°C with a water bath with a built-in stirring function, add sodium benzoate, continue to add ethanol while stirring until the sodium benzoate is completely dissolved, and record it as solution A;

[0037] 2) After fully stirring cold methanol, butanediol, diethylhydroxylamine and liquid paraffin, add solution A while stirring at a speed of 0.1-3g / min to obtain solution B, the viscosity of solution B is 2000-3000cP;

[0038]3) Stir and heat solution B to 60-70°C, then add washing oil, add polysorbate-80 and solubilizer while continuing to stir, and when the viscosity of the mixed solution reaches 10-50cP, VOC S Absorbent preparation is complete.

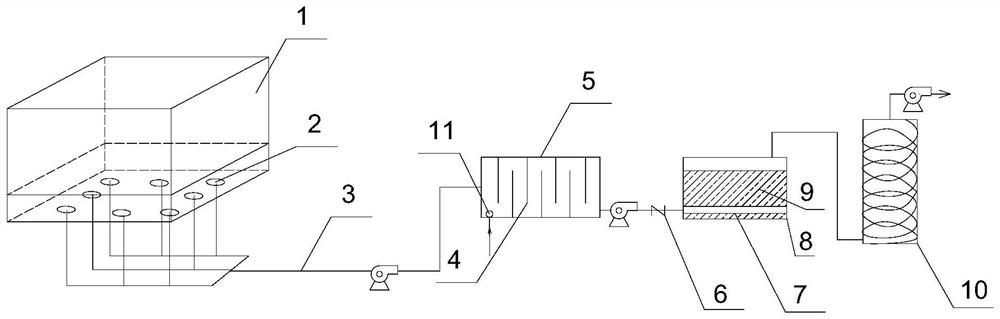

[0039] A treatment process suitable for coke gas from CDQ. The process adopts a treatment system suitable for coke gas from CDQ. The process is as follows:

[0040] 1) Utilize the axial flow fan 2 to send...

Embodiment 1

[0048] A treatment process suitable for CDQ coke output coke gas, the specific implementation is as follows:

[0049] The conveyor belt, the scraper machine, the tail bin, and the coke discharge box are all sealed into an integral bin body 1 . An axial fan 2 is arranged around the bottom of the warehouse body 1, and the exhaust gas is sent to the exhaust gas collection main pipe 3 by the fan. The waste gas collection main pipe 3 is connected with the push flow type folded plate dust interception box 5, and the push flow type folded plate dust interception box 5 is equipped with multi-layer folded plates 4, the distance between the folded plates is 1000mm, and the folded plates 4 are filled with tar dry residue, gas VOC is ejected while flowing into the plug-flow folded plate dust collection box 5 S The absorbent atomizes the liquid to make coke powder and dry residue stick together. When the gas flow rate dropped to 8m / s, the mixture was taken out, and the solid and liquid p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com