Desulfurization and Purification Process of Acid Sewage Stripping Ammonia

A purification process, a technology for ammonia gas, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of limited use of purity, no purification effect, and unsatisfactory, and achieve the effect of easy application or storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

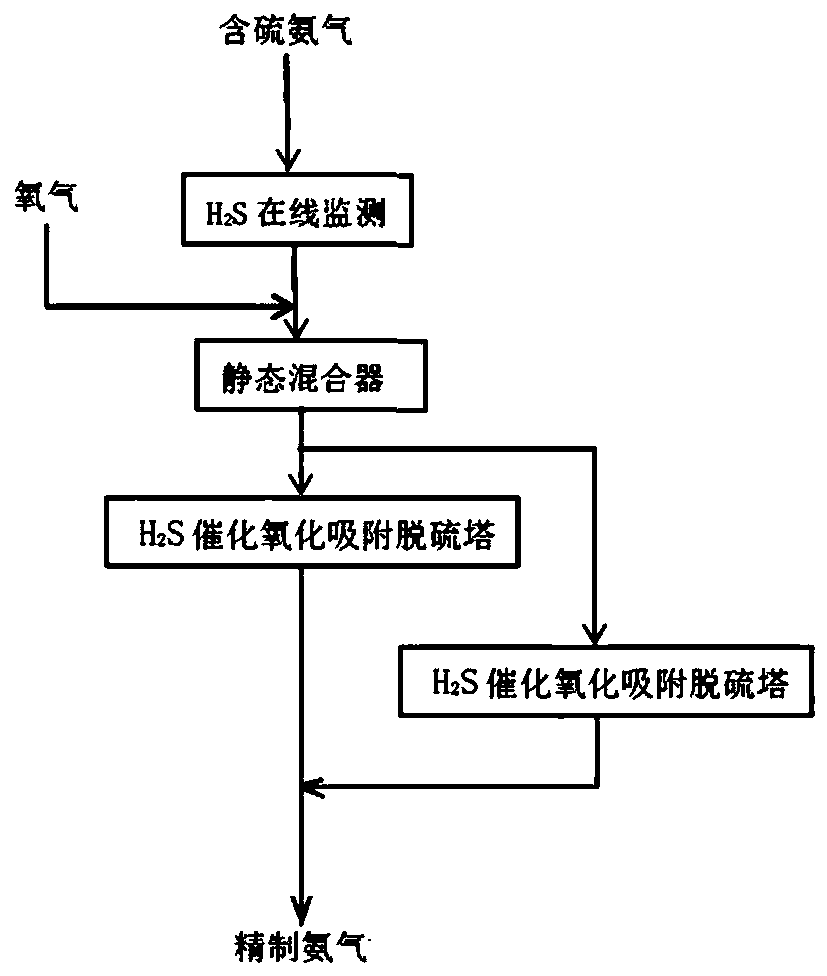

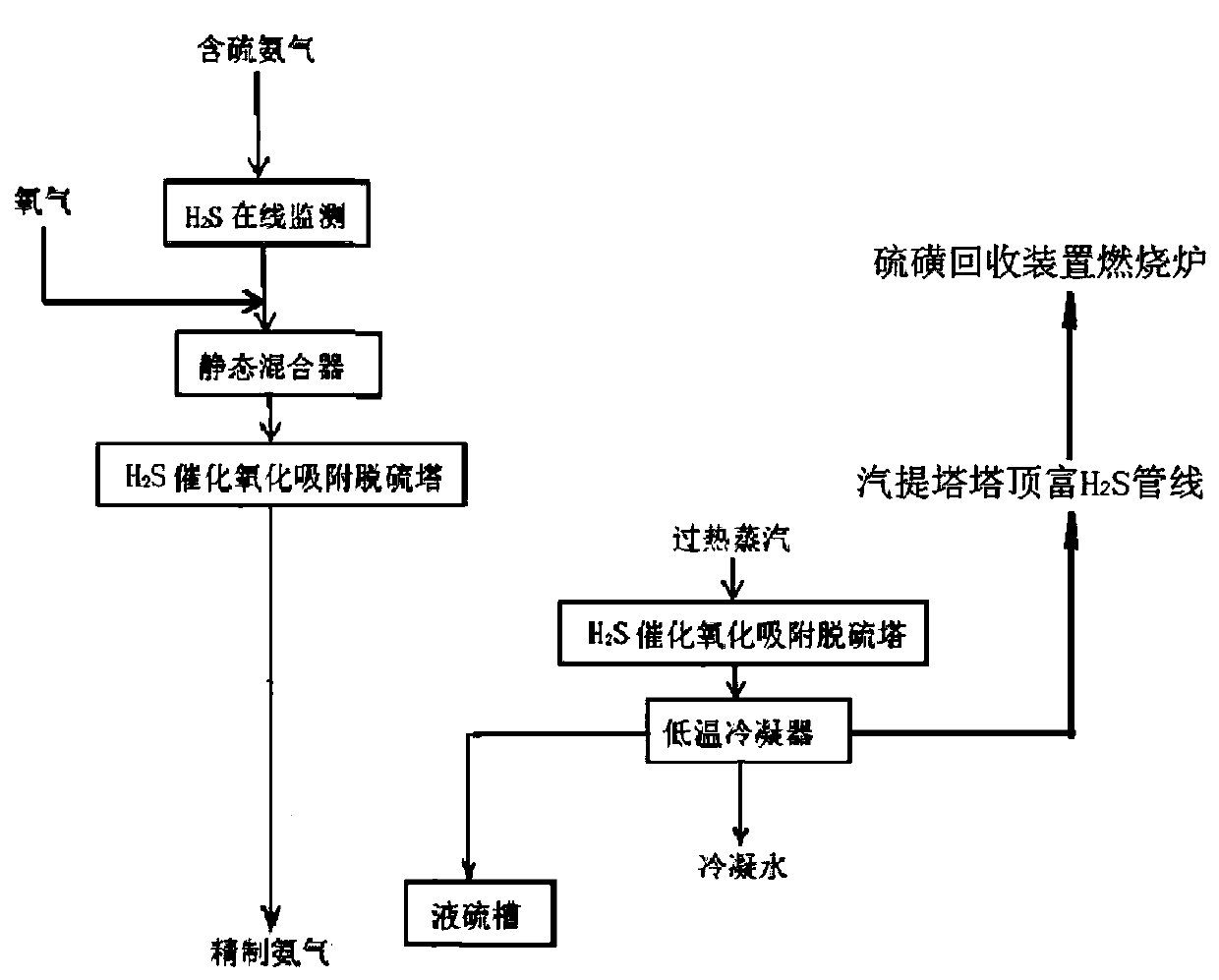

[0040] A set of ammonia gas desulfurization and purification equipment is established in the acid sewage stripping workshop of the coal chemical plant, and its process flow is as attached figure 1 shown.

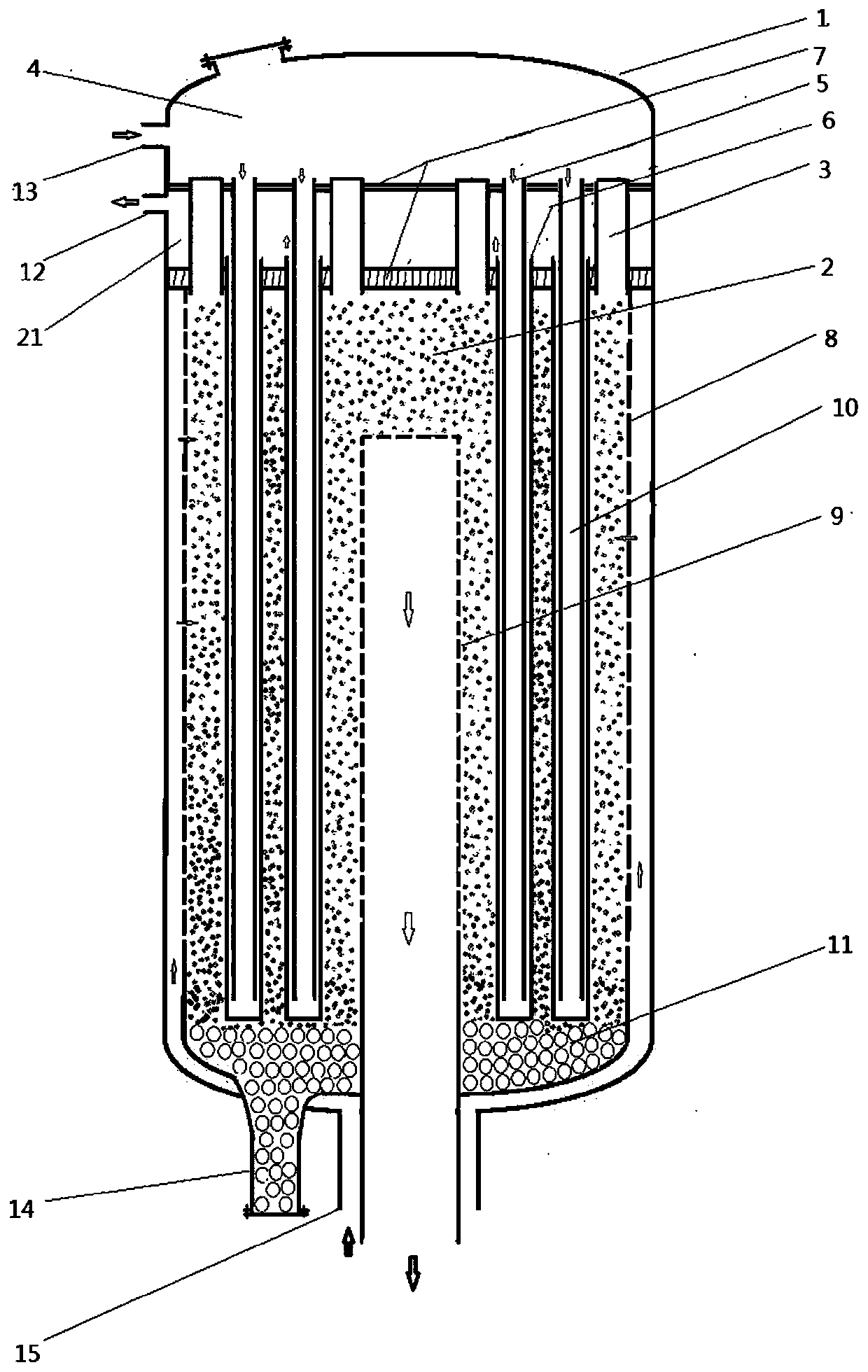

[0041] Ammonia gas desulfurization and purification device mainly includes sequentially connected H 2 S concentration online analyzer, oxygen distribution pipe and static mixer, two 20M that can be connected in series and parallel and can be cut out 3 Downflow desulfurization purification tower with vertical casing heat exchange structure; the outlet at the bottom of the desulfurization purification tower is connected to a 1M 3 Elemental sulfur condenser (water cooling, heat exchange area 15M 2 ), the condenser can be used to condense elemental sulfur during ammonia cooling or regeneration; the overall structure of the desulfurization purification tower is as attached Figure 4 As shown, ammonia gas goes in and out.

[0042] In the ammonia gas desulfurization purificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com