Treatment system and process suitable for VOCs (Volatile Organic Compounds) in tar storage tank

A processing system and storage tank technology, applied in gas processing, membrane technology, dispersed particle separation, etc., can solve the problems of low processing efficiency, increased cost, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of described VOCs absorbent is as follows:

[0050] 1) Add ethanol into the beaker, and heat it to 30-60°C with a water bath with a built-in stirring function. After the temperature stabilizes, add sodium benzoate, continue to add ethanol while stirring until the sodium benzoate is completely dissolved, and record it as solution A;

[0051] 2) After fully stirring cold methanol, butanediol, diethylhydroxylamine and liquid paraffin, add solution A while stirring at a speed of 0.1-3g / min to obtain solution B, the viscosity of solution B is 2000-3000cP;

[0052] 3) Stir and heat solution B to 60-70°C, then add washing oil, add polysorbate-80 and solubilizer during continuous stirring, and prepare the VOCs absorbent after the viscosity of the mixed solution reaches 10-50cP.

[0053] The solid recovering agent is used to absorb H 2 S, NH 3 gas, prepared as follows:

[0054] The carrier of the solid recovering agent is high specific surface modified ...

Embodiment 1

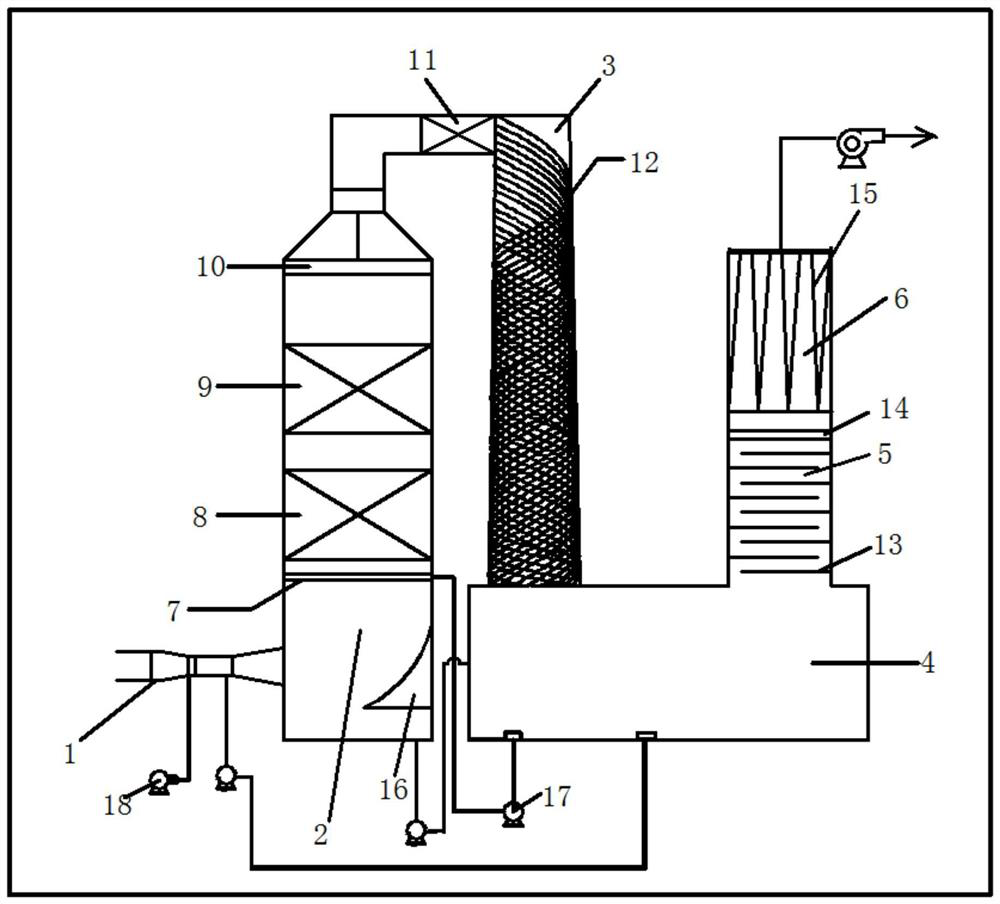

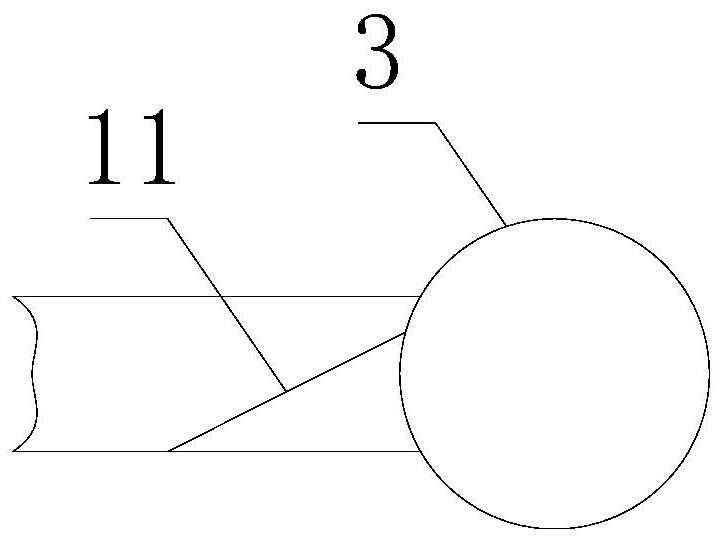

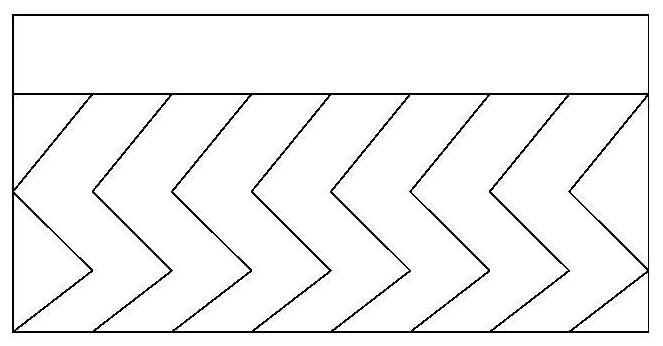

[0060] A treatment process suitable for VOCs in tar storage tanks, which mainly includes a liquid-carrying contact mixer 2, a down-rotating ridge liquid removal pipe 3, an absorption liquid collection tank 4, a reciprocating push-flow folded plate adsorption box 5, and a bundle tube type recycler6. The liquid-carrying contact mixer 2, the down-rotating ridge liquid removal pipe 3, the absorption liquid collection pool 4, the reciprocating push-flow folded plate adsorption box 5, the bundle tube type recovery unit 6 and other units pass through air ducts, fans, pumps, various The similar pipelines are connected in sequence, and the VOCs are purified in sequence. The VOCs absorbent used in the process is an efficient and environmentally friendly VOCs absorbent suitable for VOCs in tar storage tanks. The adsorbent used is a high specific surface modified slag suitable for VOCs in tar storage tanks. The recovery agent used is a suitable H 2 S, NH 3 Solid recovery agent for gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com