Desulfurization and Purification Process of Sour Water Stripping Ammonia

A purification process, ammonia technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of unsatisfactory purification effect, limited use, high energy consumption and high cost of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

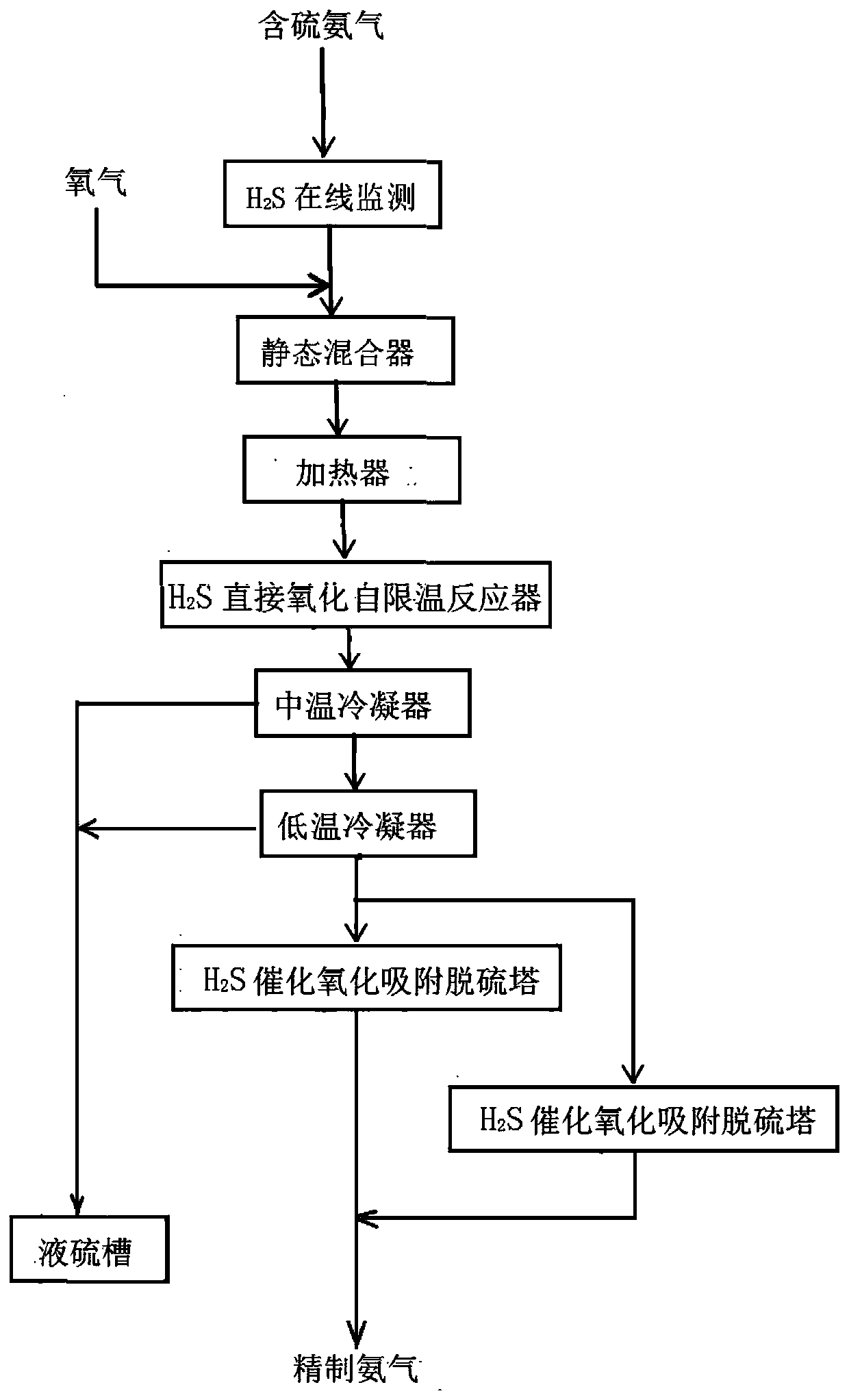

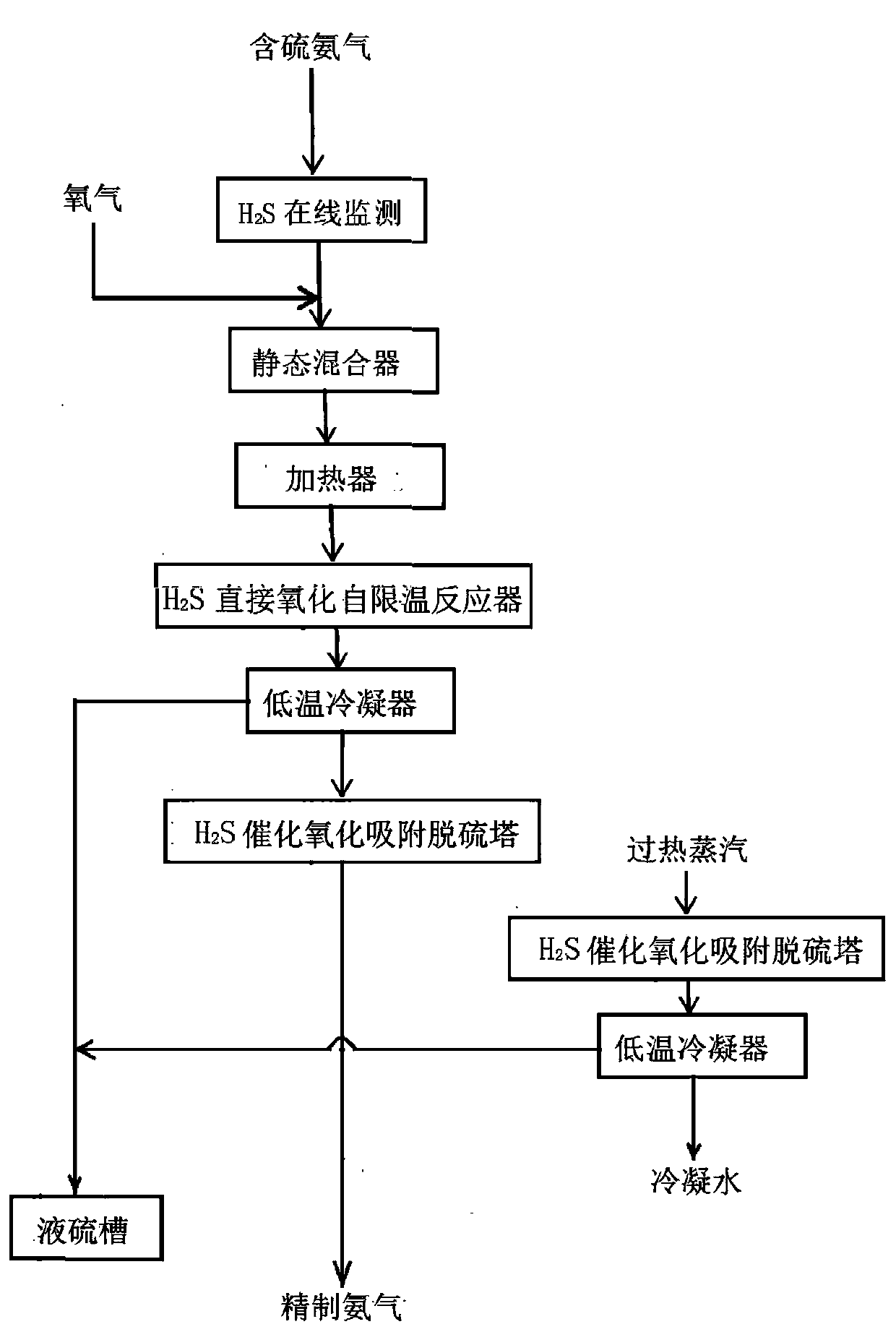

[0044] A set of ammonia gas desulfurization and purification equipment is established in the sour water stripping workshop of the refinery, and its technological process is as attached figure 1 shown.

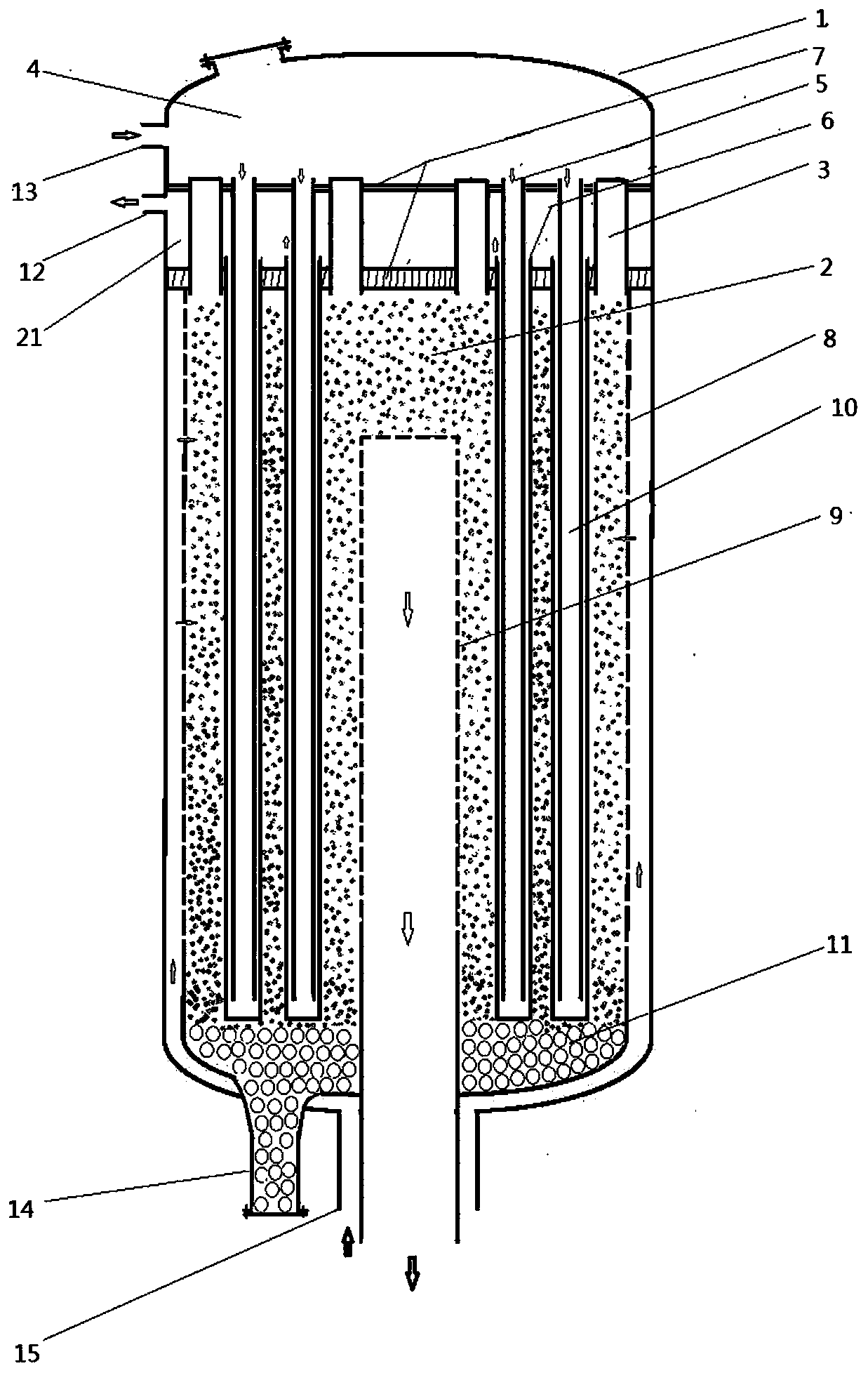

[0045] Ammonia gas desulfurization and purification device mainly includes sequentially connected H 2 S concentration online analyzer, oxygen distribution tube and static mixer, 20M 2 Heater, 6M 3 Vertical casing water-cooled self-limiting temperature H 2 S direct oxidation reactor, two 1M that can be connected in series and parallel and can be cut out 3 Elemental sulfur condenser (water cooling, heat exchange area 15M 2 ), two series-parallel and cut-out 10 M 3 Catalytic oxidation adsorption desulfurization tower; where H 2 The S direct oxidation reactor is as attached Image 6 The vertical casing water-cooled self-limiting temperature reactor with top inlet and bottom outlet shown, the middle and upper part is filled with 4.0M 3 A988TiO 2 Sulfur-based recovery cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com