Treatment system and process suitable for waste gas of circulating ammonia water tank of coking plant

A technology of circulating ammonia water and treatment system, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of complicated operation, large investment and low treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The modified CaCl 2 The particles were prepared as follows:

[0041] 1) Preparation of the carrier: Sieve siderite slag with a particle size of 5-10mm, place it in a tube furnace, and roast it at 200-250°C for 3-10h in an inert atmosphere, and add nitric acid with a concentration of 10wt%-20wt% after cooling , stirred until no more white precipitates precipitated, the cations associated with siderite may have Bi 2+ 、Ba 2+ And ammonium compounds, etc., use nitric acid to replace the surface symbiosis, which is beneficial to increase the specific surface, fully stir until no white precipitate continues to precipitate; wash the surface of the slag with deionized water to pH = 6-7, add a small amount of anhydrous Diisopropylethylamine and sodium ethylate dissolved in ethanol, the molar ratio of diisopropylethylamine and sodium ethylate is 1:1, diisopropylethylamine and sodium ethylate account for 2%-10% of the mass of the carrier, add Submerge the mixture with deionized ...

Embodiment 1

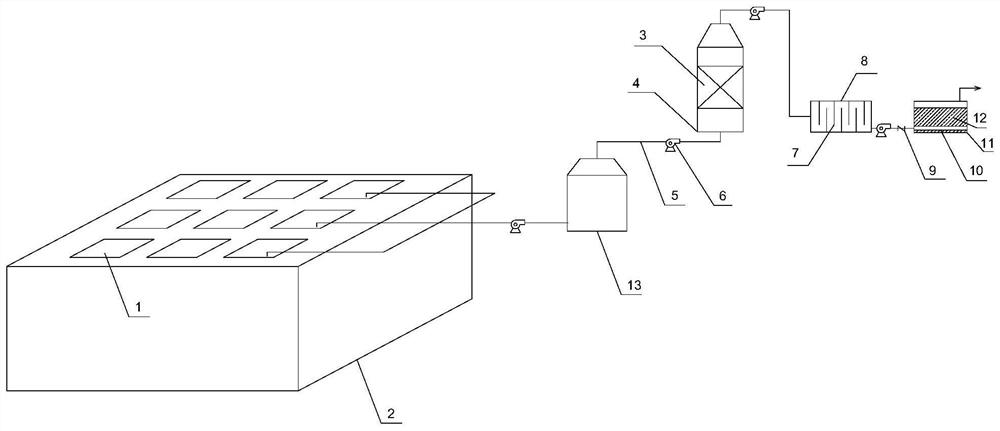

[0057] A treatment system suitable for waste gas from circulating ammonia water pools in coking plants, including waste gas collection covers 13, collection main pipes 5, ammonia absorbers 4, push-flow folded plate absorption boxes 5, absorption liquid pools 11, and cover plates above the circulating ammonia water pools 2 1 The exhaust port is connected to the exhaust gas collection cover 13 through a pipeline, and the exhaust gas collection cover 13 is connected to the collection main pipe 5, and the collection main pipe 5 is connected to the lower inlet of the ammonia collector 4, and the 4 upper end outlets of the ammonia collector are connected to push through the pipeline. A flow-type folded-plate absorption box 8, the outlet of the push-flow type folded-plate absorption box 8 is connected to the aeration pan 10 at the bottom of the absorption liquid pool 11 through a pipeline, and the aeration pan 10 is immersed in the VOCs absorbent 12; The sulfide absorbent is filled be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com