A kind of method of sulfide separation molybdenum in tungstate solution

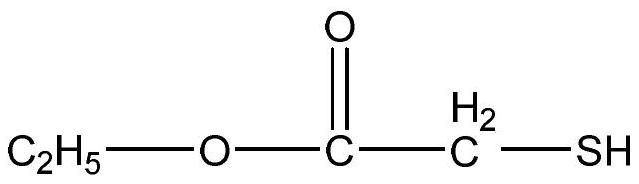

A technology of tungstate and molybdenum tungstate, which is used in the field of molybdenum removal from tungstate solution and extraction and separation of quaternary ammonium extractant, which can solve the problem of high concentration of primary amine extractant, high price of thiocyanate, and vulcanization reaction. Long time and other problems, to achieve good vulcanization effect, easy stripping, good separation effect of tungsten and molybdenum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

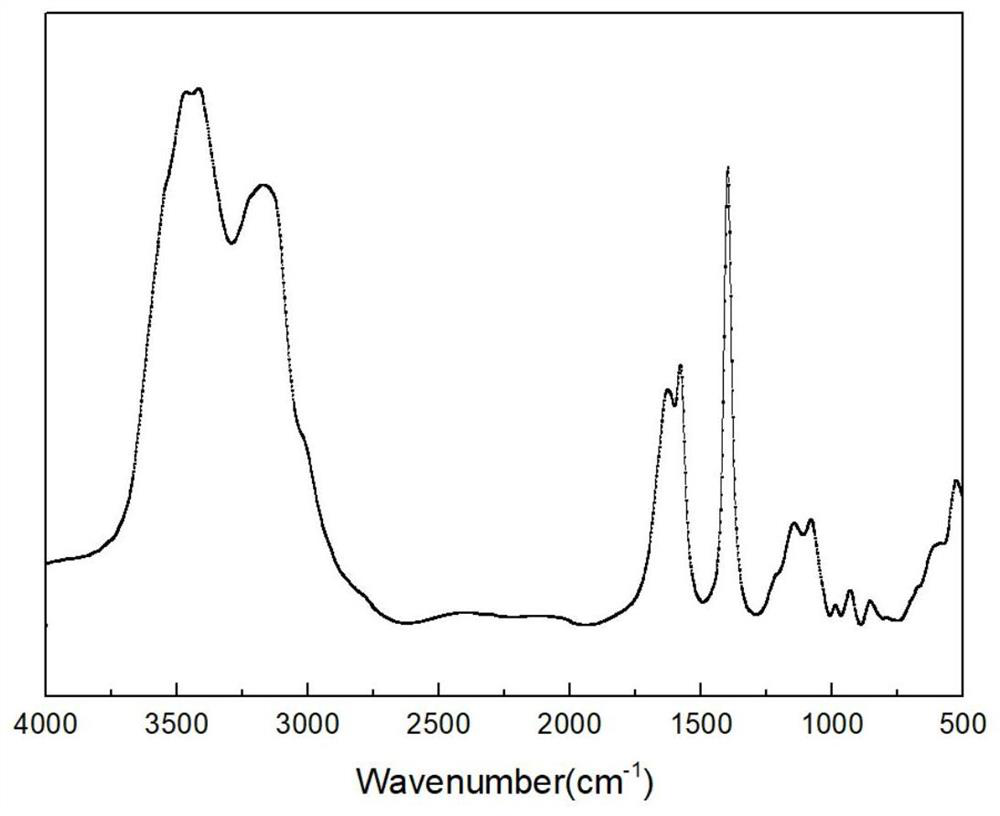

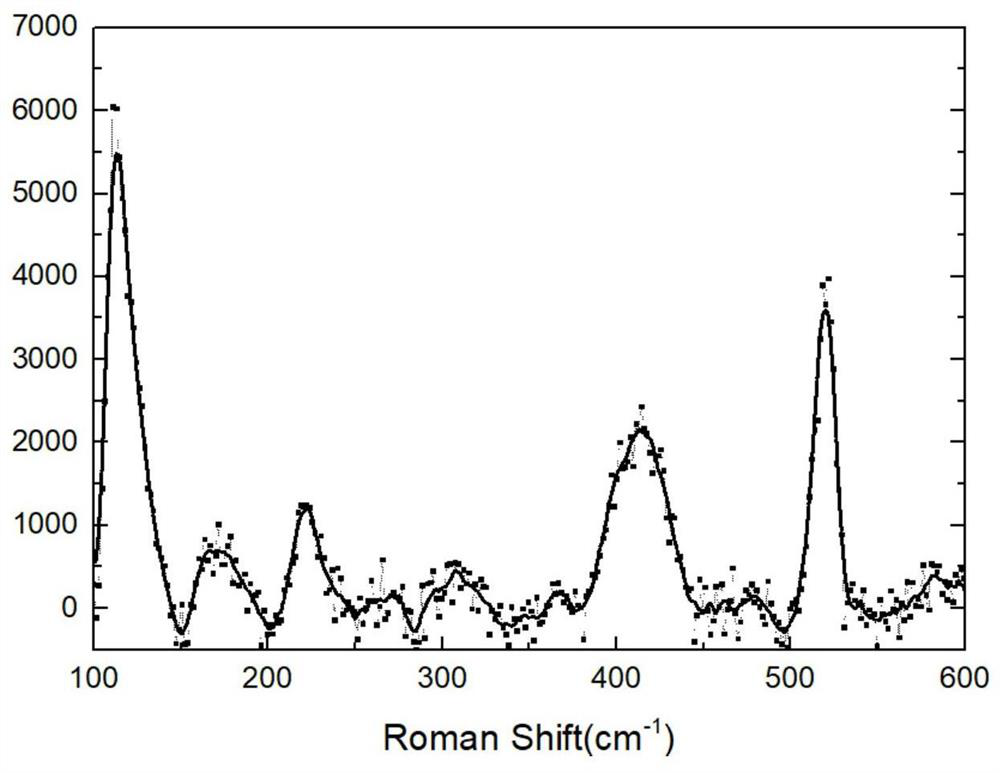

Image

Examples

Embodiment 1

[0031] The feed liquid is a molybdenum-containing ammonium tungstate solution prepared in the laboratory: the feed liquid contains Mo 1g / L, WO 330g / L. The original pH of the feed solution was 7.5. The amount of vulcanizing agent added is 1:4, 1:10, 1:20, 1:30, 1:40, 1:50, 1:60 according to the molar ratio of molybdenum and ethyl thioglycolate vulcanizing agent. Mix and stir and heat to 40°C. Insulation reaction 4h. The vulcanization rate of molybdenum under various conditions is measured in the following table.

[0032] Table 1 The effect of the amount of vulcanizing agent added on the vulcanization effect of molybdenum

[0033]

[0034] It can be seen from Table 1 that when the temperature is constant, the degree of vulcanization of molybdenum increases significantly with the increase of the amount of vulcanizing agent within the same vulcanization time.

Embodiment 2

[0036] The composition of the feed liquid is exactly the same as that in Example 1. Add the vulcanizing agent according to the molar ratio of molybdenum to ethyl mercaptoacetate vulcanizing agent is 1:20, and control the reaction temperature to be 20°C, 30°C, 40°C, 50°C, and 60°C respectively. , 70 ℃, heat preservation reaction 2h, feed liquid pre-adjusted pH = 7 or so, the vulcanization rate of molybdenum measured under each condition is shown in the table below.

[0037] Table 2 Effect of reaction temperature on molybdenum vulcanization effect

[0038]

[0039] It can be seen from Table 2 that when the amount of vulcanizing agent is constant, as the reaction temperature increases, the vulcanization effect of molybdenum is significantly improved, so an appropriate increase in temperature is beneficial to the sulfidation of molybdenum. But too high temperature may cause oxidation of vulcanizing agent to ether.

Embodiment 3

[0041] The composition of the feed liquid is exactly the same as that in Example 1. Add the vulcanizing agent according to the molar ratio of molybdenum to ethyl thioglycolate vulcanizing agent is 1:20, control the reaction temperature to 40°C, and pre-adjust the pH of the feed liquid to about 7.5, only changing the reaction Time, the reaction time is 0.5h, 1h, 2h, 3h, 4h, 5h respectively. Table 3 shows the vulcanization rate of molybdenum under various conditions.

[0042] It can be seen from Table 3 that at a certain temperature and under the condition of controlling the amount of curing agent, prolonging the curing time can increase the curing rate of molybdenum, and the effect of curing time is not as significant as the amount of curing agent and reaction temperature.

[0043] The influence of table 3 reaction time on molybdenum vulcanization effect

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com