Oil sand separation method

A separation method and oil sand technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of asphalt residue, etc., and achieve the effect of low production cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

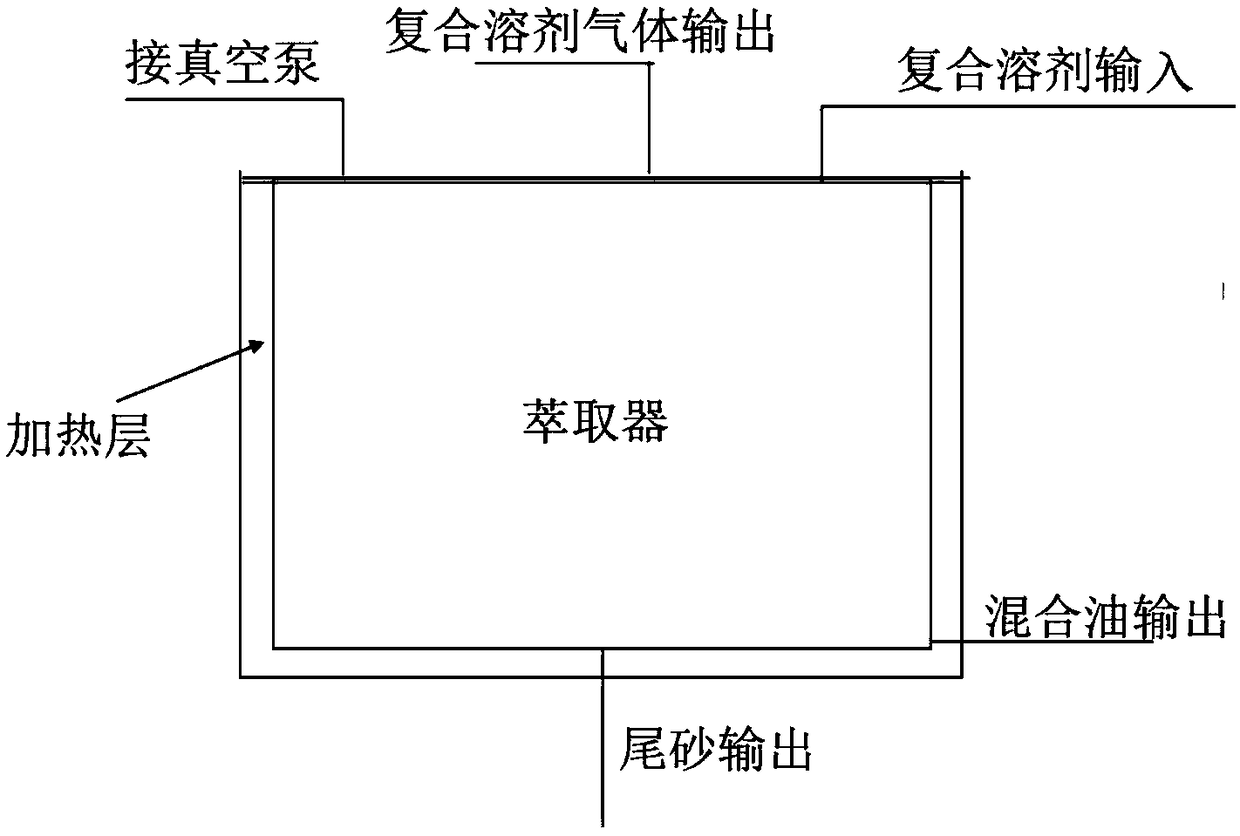

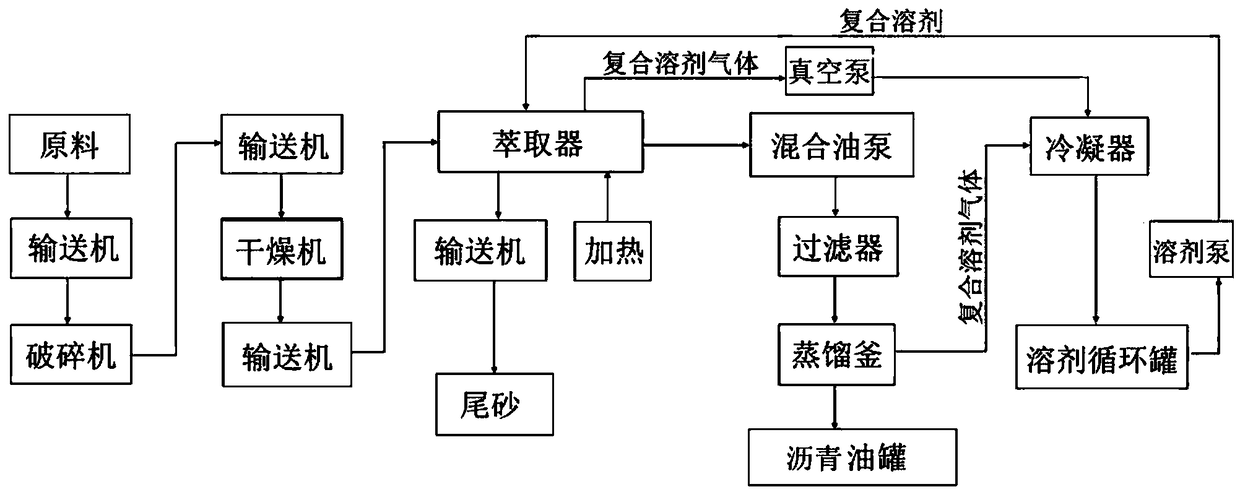

[0032] The oil sand separation method of this embodiment, the flow process is as follows figure 2 , including the following steps:

[0033] (1) Oil sand raw materials include minerals such as natural asphalt, sand and clay, water, and asphalt oil content of 22.54% (Indonesian oil sands); oil sand raw materials are transported to a pulverizer by a conveyor, and crushed to particles with a particle size of less than 10mm; Then it is transported to the dryer by the conveyor, and after drying and dehydration at 50-65°C, it is transported to the extractor by the conveyor.

[0034] (2) The oil sand is extracted by the composite solvent in the extractor. The composite solvent is placed in the solvent circulation tank, and after being extracted from the solvent circulation tank by the solvent pump, it enters the extractor through the solvent inlet; the use of the composite solvent The amount is 0.5 wt.% of the weight of the oil sands feedstock. The temperature of the extraction tre...

Embodiment 2

[0038] The difference from Example 1 is:

[0039] The composition of the composite solvent is: No. 120 mineral spirits 60wt.%, petroleum ether 24.5wt.%, n-heptane 15.5wt.%.

[0040] According to the operation steps of Example 1, after the oil sand raw materials are separated and extracted, the extraction rate of bitumen in the oil sand is over 98.67%.

[0041] In the separated sand and stone, 0.3% of asphalt remains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com