Modification method for catalyst applied to reaction of 3,5-dimethylpyridine and pyridine

A lutidine, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of excess pyridine, insufficient 3-picoline market supply, 3-picoline chemical reaction Problems with low yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

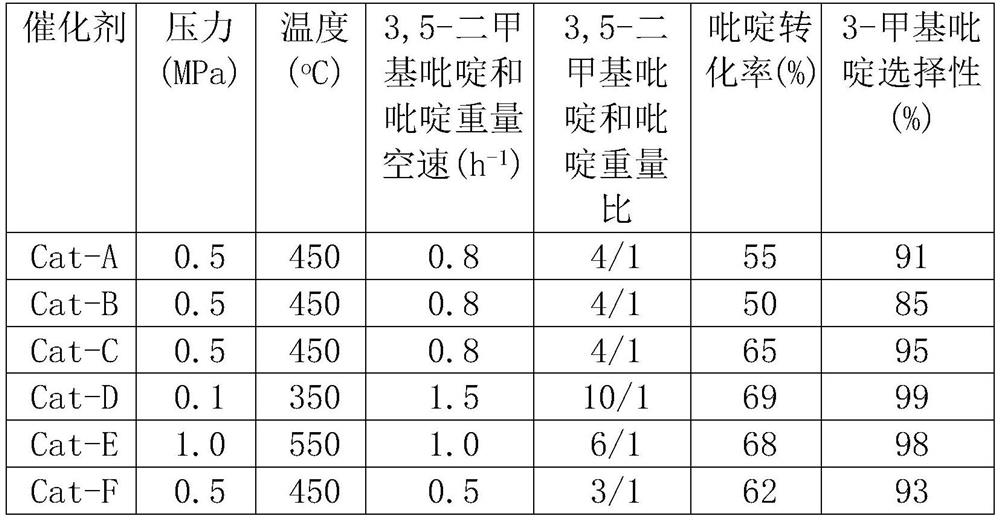

[0024] Mix 8g of HZSM-5 molecular sieve with 2g of silica gel, extrude, dry at 120°C for 4 hours, calcined at 540°C for 3 hours, then place the calcined catalyst in a steam environment for steam treatment at 600°C , the time is 4 hours, and the catalyst Cat-C is prepared. The reaction properties of the prepared catalysts are shown in Table 1.

Embodiment 2

[0026] Mix 4.5g HZSM-5 molecular sieve with 18.3g silica sol (solid content 30wt%), extrude, dry at 85°C for 9 hours, and bake at 580°C for 4.5 hours, then steam treatment at 500°C for After 4 hours, catalyst Cat-D was prepared. The reaction properties of the prepared catalysts are shown in Table 1.

Embodiment 3

[0028] Mix 9g of HZSM-5 molecular sieve with 1.25g of white carbon black (dry basis 80wt%), extrude, dry at 100°C for 7 hours, and bake at 480°C for 3 hours, then steam treatment at 680°C for After 7 hours, catalyst Cat-E was prepared. The reaction properties of the prepared catalysts are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com