Ultrasonic-assisted method for extracting pepper oleoresin

A technology of ultrasonic-assisted extraction and pepper oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of long extraction time and low extraction rate of pepper oleoresin, and achieve outstanding substantive characteristics, bright color and raw material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

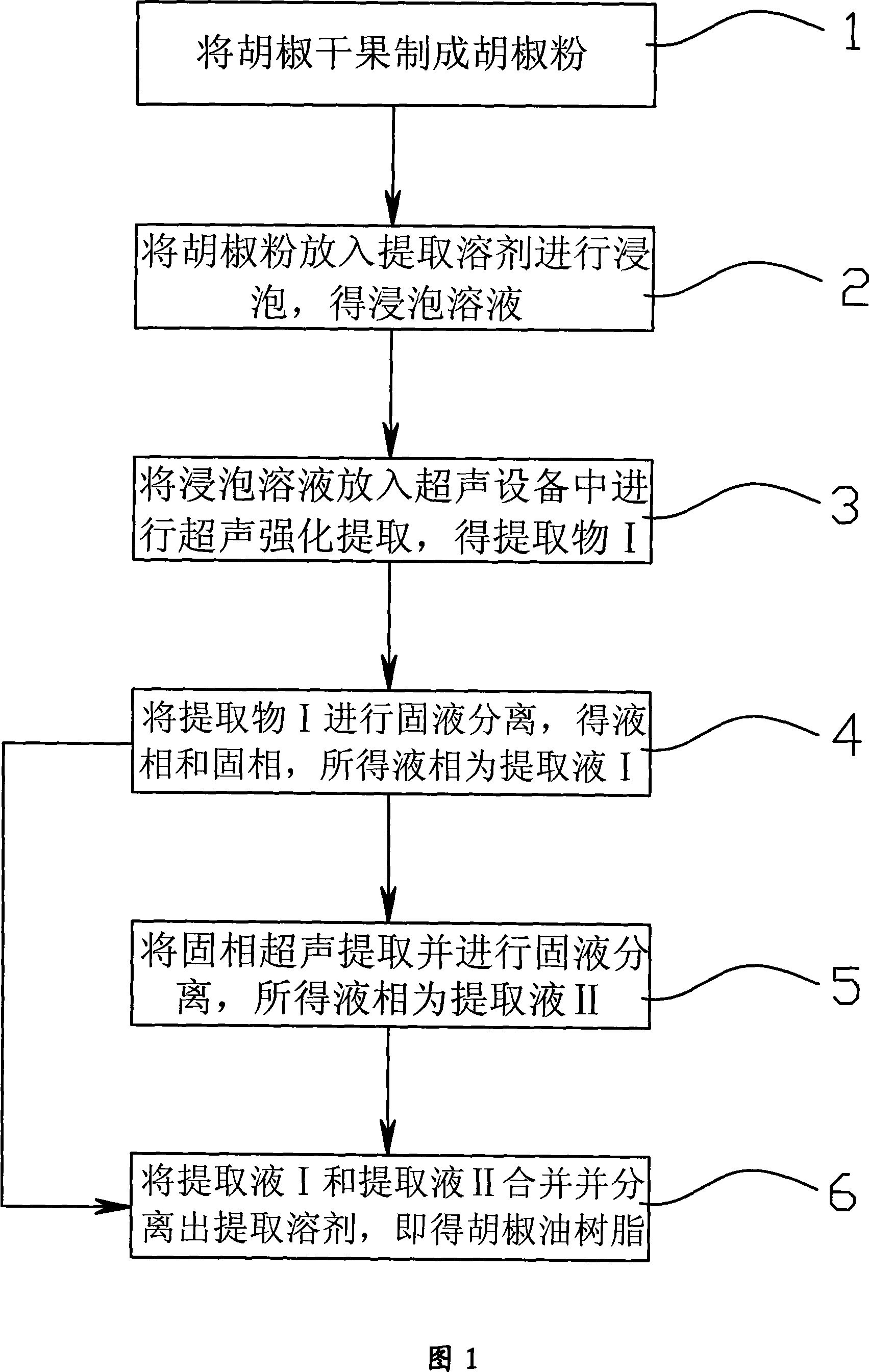

[0030] As shown in Fig. 1, a kind of ultrasonic-assisted method for extracting pepper oleoresin comprises following extraction steps:

[0031] Step 1. Clean 100 kilograms of selected white pepper dried fruits, dry or dry them, crush them, and pass through a 40-mesh sieve to make pepper powder;

[0032] Step 2, put the pepper powder obtained in step 1 into 800 kilograms of 95% ethanol and soak for half an hour, and the soaking temperature is 40° C. to obtain a soaking solution;

[0033] Step 3. Put the soaking solution obtained in step 2 into an ultrasonic device for ultrasonic enhanced extraction, wherein the ultrasonic extraction frequency is 40KHz, and the ultrasonic intensity is 20W / cm 2 , the extraction temperature was 48° C., and the extraction time was 50 minutes to obtain extract I;

[0034] Step 4, the extract I obtained in step 3 is subjected to solid-liquid separation by vacuum filtration to obtain a liquid phase and a solid phase, and the obtained liquid phase is t...

Embodiment 2

[0038] A method for ultrasonically assisted extraction of pepper oleoresin, comprising the following extraction steps:

[0039] Step 1. Clean 120 kilograms of selected white pepper dried fruits, dry or dry them, crush them, and pass through a 60-mesh sieve to make pepper powder;

[0040] Step 2, put the pepper powder obtained in step 1 into 1000 kilograms of acetone solution and soak for 40 minutes, and the soaking temperature is 50° C. to obtain the soaking solution;

[0041] Step 3. Put the soaking solution obtained in step 2 into an ultrasonic device for ultrasonic enhanced extraction, wherein the ultrasonic extraction frequency is 45KHz, and the ultrasonic intensity is 25W / cm 2 , the extraction temperature is 50°C, and the extraction time is 60 minutes to obtain the extract I;

[0042] Step 4, the extract I obtained in step 3 is subjected to solid-liquid separation by vacuum filtration to obtain a liquid phase and a solid phase, and the obtained liquid phase is the extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com