Comprehensive utilization method for directly extracting lithium by silicate-based lithium-containing ore acid process

A technology of lithium ore and silicate, which is applied in the field of lithium extraction from ore, can solve the problems of increased production cost, low resource utilization rate, and large equipment corrosion, and achieve the goals of reduced production energy consumption, no discharge of three wastes, and wide adaptability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

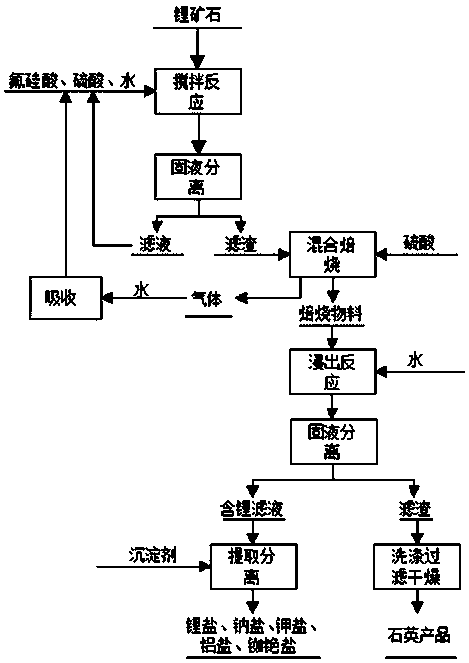

Image

Examples

Embodiment 1

[0037] The natural α-type spodumene is crushed and ground and sieved to D 90 =62.630μm, to obtain spodumene powder, make slurry with fluosilicic acid (100%), sulfuric acid (100%), and water at a mass ratio of 1:0.2:0.3:4, and put it into a stirring reactor , the reaction was continuously stirred at 70°C for 4h. After the reaction is completed, filter, and the obtained filtrate is recycled to make a slurry with spodumene powder. The obtained filter cake is mixed with concentrated sulfuric acid (the concentration of sulfuric acid is greater than 80%, and the conversion is 100%) according to the weight ratio of 1:0.6. In the roasting furnace, roast at 290°C for 0.5h. After the roasting is completed, the obtained roasted material and water are mixed and stirred at a mass ratio of 1:3 for leaching. The temperature of leaching is controlled at 30°C for 1h. After the leaching is completed, it is filtered and washed, and the obtained lithium-containing filtrate is used to produce lit...

Embodiment 2

[0039] Lepidolite is crushed and ground and sieved to D 90=54.354μm, to obtain lepidolite powder, make slurry with fluosilicic acid (100%), sulfuric acid (100%), and water at a mass ratio of 1:0.5:0.2:6, and put it into a stirred reactor , The reaction was continuously stirred at 50° C. for 3 h. After the reaction is completed, filter, and the obtained filtrate is recycled to make a slurry with spodumene powder, and the obtained filter cake is mixed with concentrated sulfuric acid (the concentration of sulfuric acid is greater than 80%, and the conversion is 100%) according to the weight ratio of 1:0.8, and then put into In the roasting furnace, roast at 260°C for 1 hour. After the roasting is completed, the obtained roasted material and water are mixed and stirred according to the mass ratio of 1:5. After the leaching is completed, it is filtered and washed, and the obtained lithium-containing filtrate is used to produce lithium salts, sodium salts, potassium salts, aluminum...

Embodiment 3

[0041] Lithium china stone is crushed and ground and sieved to D 90 =82.777μm, to obtain lithium china stone powder, make slurry with fluosilicic acid (100%), sulfuric acid (100%), and water at a mass ratio of 1:0.3:0.4:8, and put it into a stirring reactor , the reaction was continuously stirred at 90°C for 2h. After the reaction is completed, filter, and the obtained filtrate is recycled to make a slurry with spodumene powder. The obtained filter cake is mixed with concentrated sulfuric acid (the concentration of sulfuric acid is greater than 80%, and the conversion is 100%) according to the weight ratio of 1:1. In the roasting furnace, roast at 300°C for 1 hour. After the roasting is completed, the obtained roasted material and water are mixed and stirred according to the mass ratio of 1:7. After the leaching is completed, it is filtered and washed, and the obtained lithium-containing filtrate is used to produce lithium salts, sodium salts, potassium salts, aluminum salts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com