Method of selectively extracting and separating molybdenum from high-phosphorus tungsten- and molybdenum-containing mixed solution

A mixed solution and selective technology, which is applied in the field of tungsten and molybdenum metallurgy, can solve the problem of not being able to directly process and separate molybdenum, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Organic phase composition (volume percentage): 90% TBP+10% sulfonated kerosene.

[0031] Raw material liquid: a company uses sulfur-phosphorus mixed acid to treat the leaching liquid obtained from high-molybdenum scheelite, containing WO 3 120.5g / L, Mo 12.05g / L, phosphoric acid concentration 1.3mol / L, sulfuric acid concentration 1.1mol / L.

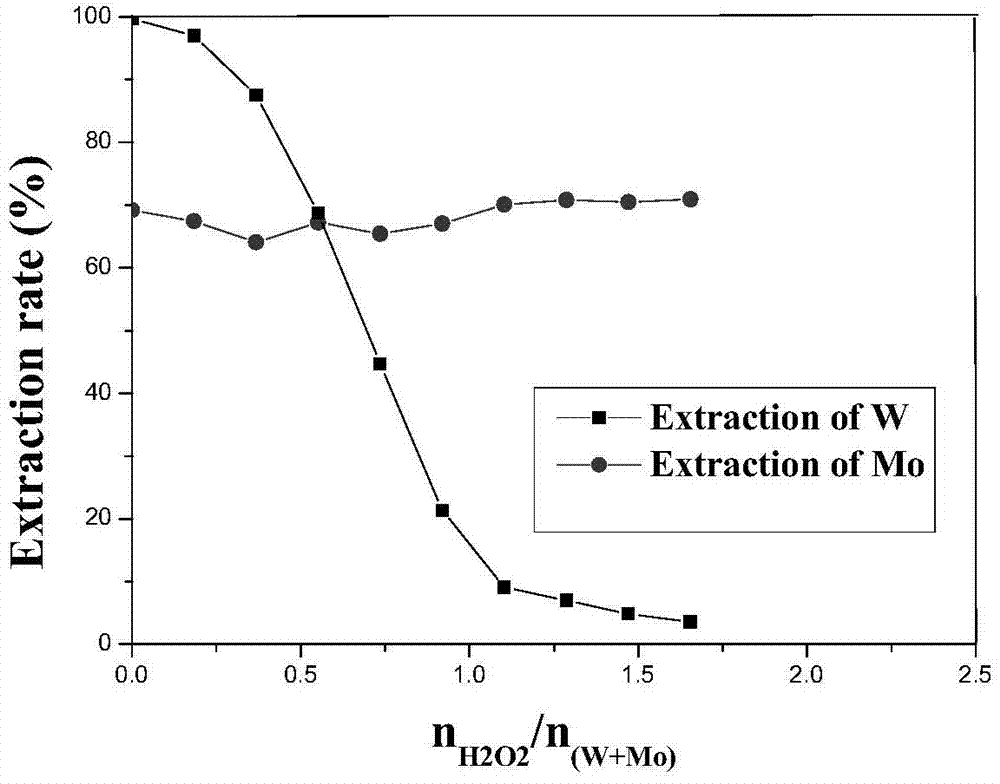

[0032] Feed liquid adjustment: add H at a concentration of 30% to it 2 o 2 solution, H 2 o 2 The added amount is 1.4 times of the total amount of moles of tungsten and molybdenum. get containing WO 3 114.1g / L, Mo 11.41g / L, WO 3 / Mo=10 / 1, a hydrogen peroxide-containing feed solution with a phosphoric acid concentration of 1.2 mol / L and a sulfuric acid concentration of 1 mol / L.

[0033] Extraction and separation: the above-mentioned organic phase and aqueous phase feed liquid are subjected to 5-stage countercurrent extraction under the condition of 1 / 1 ratio, and the loaded organic phase is back-extracted with 4mol / L ammonia aqu...

Embodiment 2

[0036] Organic phase composition (volume percentage): 80% TBP+20% sulfonated kerosene.

[0037] Raw material liquid: a company uses phosphate to decompose high-molybdenum scheelite under alkaline conditions. The leaching liquid contains WO 3 105.3g / L, Mo 5.27g / L, phosphorus concentration 0.82mol / L, sodium hydroxide concentration 0.4mol / L.

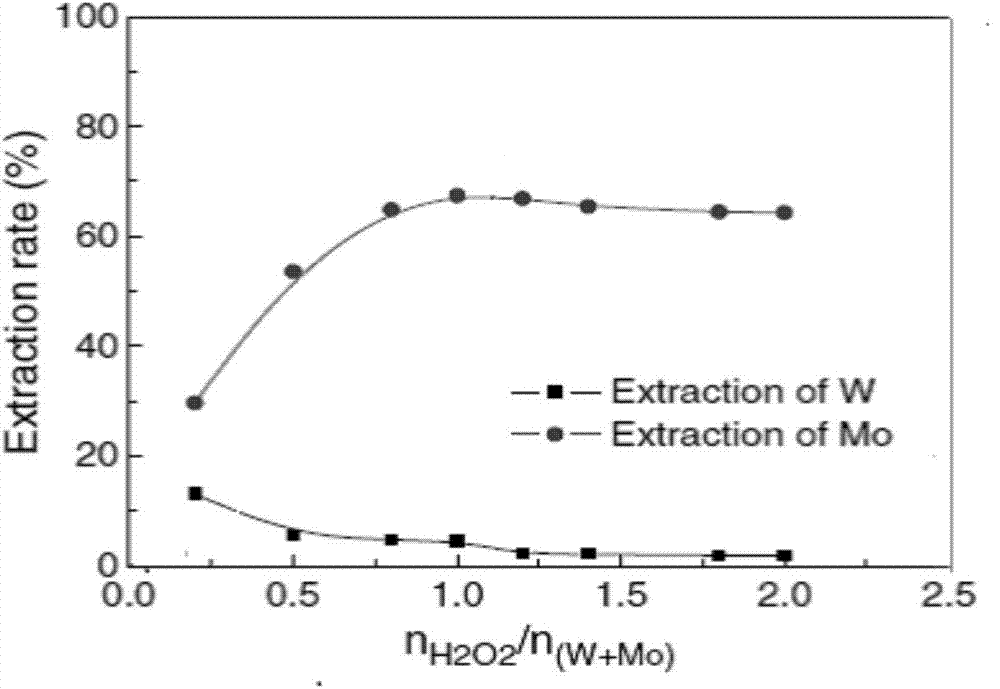

[0038] Feed liquid adjustment: add sulfuric acid thereinto, the final feed liquid containing sulfuric acid concentration is 1.4mol / L; And add concentration is 30% H 2 o 2 solution, H 2 o 2 The added amount is 0.8 times of the total amount of moles of tungsten and molybdenum. The final result contains WO 3 90.5g / L, Mo 4.53g / L, WO 3 / Mo=20 / 1, a hydrogen peroxide-containing feed solution with a phosphorus concentration of 0.7mol / L and a sulfuric acid concentration of 1.4mol / L.

[0039] Extraction and separation: the organic phase and the aqueous phase feed liquid are subjected to 5-stage countercurrent extraction under the condition of ...

Embodiment 3

[0042] Organic phase composition (volume percent): 70% TBP+30% benzene.

[0043] Raw feed liquid: feed liquid contains WO 3 10.2g / L, Mo 102.9g / L, phosphorus concentration 4.5mol / L, nitric acid concentration 2.6mol / L, hydrochloric acid concentration 1.9mol / L.

[0044] Feed liquid adjustment: add H at a concentration of 30% to it 2 o 2 solution, H 2 o 2 The added amount is 1.2 times of the total amount of moles of tungsten and molybdenum. get containing WO 3 9g / L, Mo 90.8g / L, WO 3 / Mo=1 / 10, a hydrogen peroxide-containing feed solution with a phosphorus concentration of 4mol / L, a nitric acid concentration of 2.3mol / L, and a hydrochloric acid concentration of 1.7mol / L.

[0045] Extraction and separation: the above-mentioned organic phase and aqueous phase feed liquid are subjected to 7-stage countercurrent extraction under the condition of ratio 2 / 1, and the loaded organic phase is back-extracted with 1mol / L ammonium carbonate aqueous solution under the condition of ratio 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com