Catalyst for extracting and separating uranium in uranium-containing wastewater or seawater and application of catalyst

A catalyst and wastewater technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of oxidation and redissolution of extracted uranium, affecting the efficiency of photocatalytic reduction, reoxidation of uranium reduction products, Dissolution and other problems, to achieve the effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

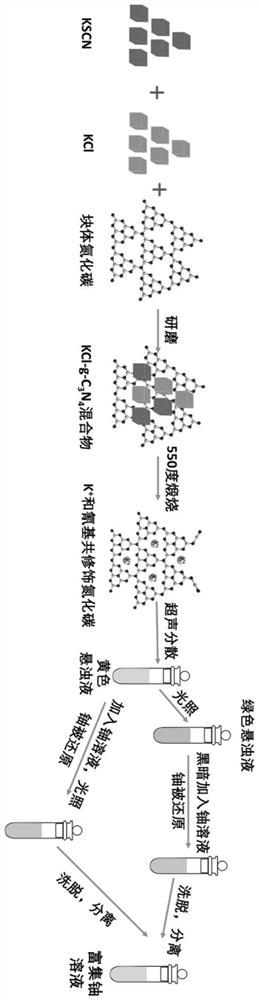

[0047] The present embodiment provides a catalyst for extracting and separating uranium in uranium-containing wastewater or seawater, which is prepared by the following steps:

[0048] According to the mass ratio of 1:2:6, the corresponding masses of carbon nitride, potassium thiocyanate and potassium chloride were respectively weighed, and then mixed uniformly by grinding and then placed in a quartz boat and placed in a tube furnace at 8°C. The temperature was raised to 550 °C at a rate of / min and kept for 4 h to obtain a light yellow solid catalyst precursor;

[0049] Then the catalyst precursor was ground into powder, and the ground catalyst precursor was washed several times with ultrapure water until no K was detected in the washing solution after washing. + , and then washed the ground catalyst precursor with anhydrous ethanol several times to wash away alcohol-soluble impurities in the catalyst precursor, thereby reducing the influence of other substances on the cataly...

Embodiment 2

[0051] The present embodiment provides a catalyst for extracting and separating uranium in uranium-containing wastewater or seawater, which is prepared by the following steps:

[0052] According to the mass ratio of 1:3:5, the corresponding masses of carbon nitride, potassium thiocyanate and potassium chloride were respectively weighed, and then mixed uniformly by grinding and then placed in a quartz boat and placed in a tube furnace at 8°C. The temperature was raised to 550 °C at a rate of / min and kept for 4 h to obtain a light yellow solid catalyst precursor;

[0053] Then the catalyst precursor was ground into powder, and the ground catalyst precursor was washed several times with ultrapure water until no K was detected in the washing solution after washing. + , and then washed the ground catalyst precursor with anhydrous ethanol several times to wash away alcohol-soluble impurities in the catalyst precursor, thereby reducing the influence of other substances on the catalyti...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is:

[0056] In this embodiment, the mass ratio of carbon nitride, potassium chloride and potassium thiocyanate is 1:1:4.

[0057] In this embodiment, the holding temperature is 500°C, the holding time is 5h, and the heating rate is 5°C / min.

[0058] In this embodiment, the vacuum degree of the freeze-drying treatment is below 10 Pa, the treatment temperature is -15 to -5° C., and the treatment time is 8 to 16 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com