High phosphorus and low sulfur non-oriented electrical steel and its smelting method

A technology of oriented electrical steel and high phosphorus, which is applied in the field of metallurgy, can solve the problems of composition control without clearly specifying the control scheme, and achieve iron loss and magnetic satisfaction, good quality, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

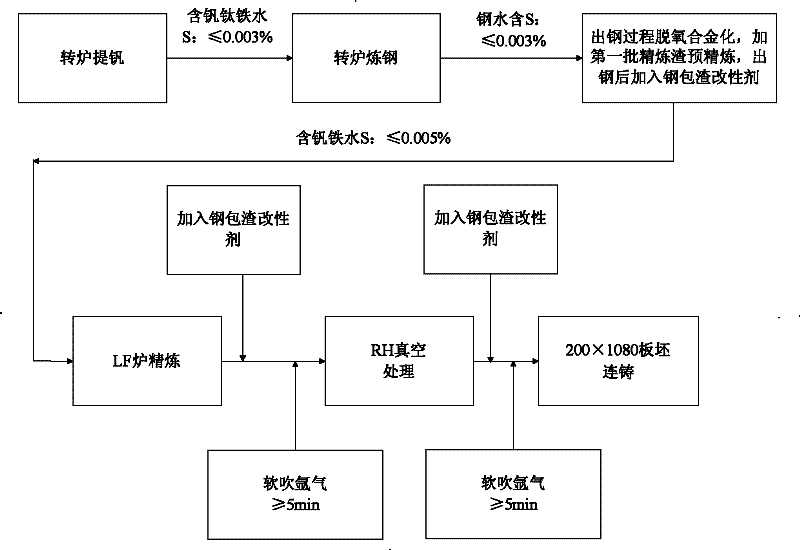

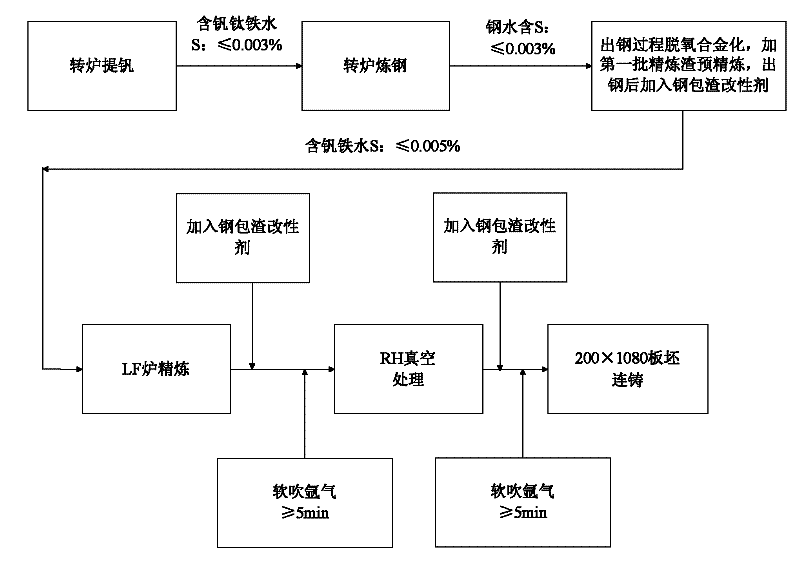

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 Preparation of high-phosphorus and low-sulfur electrical steel of the present invention

[0052] Using molten iron containing vanadium and titanium as raw materials, its main components are: 4.02% C, 0.27% V, 0.17% Mn, 0.003% S, 0.072% P, 0.22% Si, 0.17% Ti and a small amount of unavoidable impurities; the molten iron Add 120t of compound blowing vanadium extraction converter for blowing, the amount of mixing is 135t, then add coolant into the vanadium extraction converter, and use 339 oxygen lances to supply oxygen and blow vanadium, within 2 to 3 minutes of blowing vanadium, blow vanadium into the furnace After adding 2t of iron oxide scale and supplying oxygen for 4.5 minutes, add 300kg of magnesia to the furnace for slag adjustment, and then supply oxygen for 40 seconds to block slag and remove semi-steel and vanadium slag. The final temperature of blowing is 1435°C. The composition of the obtained semi-steel is: 3.40%C, 0.07%Mn, 0.062%P, 0.004%S, 0.028...

Embodiment 2

[0056] Example 2 Preparation of high-phosphorus and low-sulfur electrical steel of the present invention

[0057]Using molten iron containing vanadium and titanium as raw materials, its main components are: 4.05% C, 0.28% V, 0.16% Mn, 0.002% S, 0.068% P, 0.21% Si, 0.16% Ti and a small amount of unavoidable impurities; the molten iron Add 120t of compound blowing vanadium extraction converter for blowing, the amount of mixing is 135t, then add coolant into the vanadium extraction converter, and use 339 oxygen lances to supply oxygen and blow vanadium, within 2 to 3 minutes of blowing vanadium, blow vanadium into the furnace After adding 2t of iron oxide scale and supplying oxygen for 4.7 minutes, add 300kg of magnesia to the furnace for slag adjustment, and then supply oxygen for 30 seconds to block slag and remove semi-steel and vanadium slag. The end temperature of blowing is 1433°C. The composition of the obtained semi-steel is: 3.38%C, 0.06%Mn, 0.058%P, 0.003%S, 0.027%V and...

Embodiment 3

[0062] Example 3 Preparation of high-phosphorus and low-sulfur electrical steel of the present invention

[0063] Using molten iron containing vanadium and titanium as raw materials, its main components are: 4.10% C, 0.27% V, 0.13% Mn, 0.003% S, 0.075% P, 0.20% Si, 0.14% Ti and a small amount of unavoidable impurities; the molten iron Add 120t of compound blowing vanadium extraction converter for blowing, the amount of mixing is 135t, then add coolant into the vanadium extraction converter, and use 339 oxygen lances to supply oxygen and blow vanadium, within 2 to 3 minutes of blowing vanadium, blow vanadium into the furnace After adding 2t of iron oxide scale and supplying oxygen for 4.8 minutes, add 300kg of magnesia to the furnace for slag adjustment, and then supply oxygen for 35 seconds to block slag and remove semi-steel and vanadium slag. The final temperature of blowing is 1428°C. The composition of the semi-steel obtained is: 3.41%C, 0.07%Mn, 0.082%P, 0.003%S, 0.026%V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com