Filler special for artificial wetland and preparation method thereof

A technology of artificial wetlands and raw materials, applied in the direction of chemical instruments and methods, applications, household appliances, etc., can solve the problems such as the decrease of phosphorus adsorption rate, and achieve the effect of large porosity, long service life and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

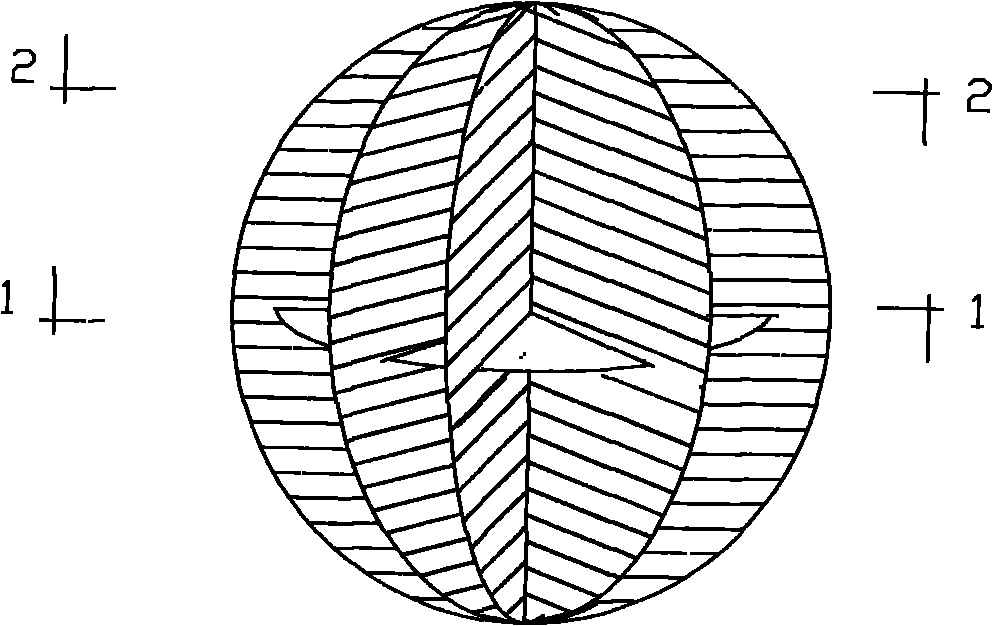

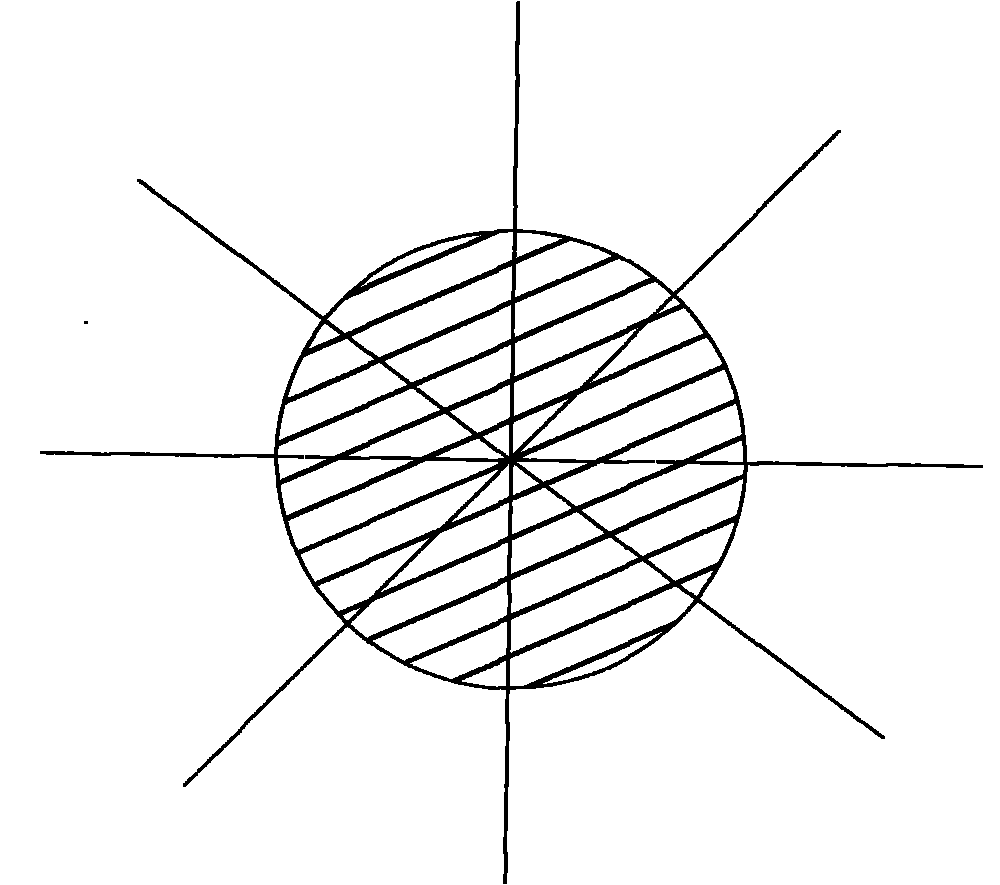

[0026] The raw material is the fly ash of Nanjing Thermal Power Plant. Mix 10g of fly ash and 80g of 32.5 portland cement with about 45g of water, add 0.015g of aluminum powder, stir evenly, put it into the mold and put In the constant temperature box, let it stand for 20 minutes to foam, and then cure it at room temperature for half a day, and you can get a lightweight, porous hollow ball artificial wetland filler with a radius of 2.5cm. Its structural diagram is as figure 1 , figure 2 , image 3 shown.

[0027] Phosphorus removal test of domestic sewage was carried out using the phosphorus adsorption material made by the above process. The phosphorus content in raw domestic sewage water is 5.1mg / l. Put 10g of the special filler for constructed wetland into a 300ml Erlenmeyer flask of domestic sewage, and the hydraulic retention time is 2 hours. After treatment, the concentration of phosphorus in the effluent is 0.6mg / l, and the removal rate of phosphorus is 88.2%.

Embodiment 2

[0029] The raw material is the fly ash of Nanjing Thermal Power Plant. Mix 15g of fly ash and 90g of 42.5 Portland cement with about 40g of water, add 0.010g of aluminum powder, stir evenly, add it to the mold, and put it into the mold at 40°C In a constant temperature box, let it stand for 30 minutes to foam, and then cure it at room temperature for 1 day, and you can get a lightweight, porous hollow ball artificial wetland filler with a radius of 3cm.

[0030] The phosphorus adsorption material made by the above process was used to carry out the phosphorus removal test of higher concentration sewage. The phosphorus content of raw sewage water is 10mg / l. Put 10g of the special filler for constructed wetland into a 300ml Erlenmeyer flask of domestic sewage, and the hydraulic retention time is 2 hours. After treatment, the concentration of phosphorus in the effluent was 1.44mg / l, and the removal rate of phosphorus was 85.6%.

Embodiment 3

[0032] The raw material is the fly ash of Nanjing Thermal Power Plant. Mix 20g of fly ash and 100g of 52.5 Portland cement with about 50g of water, add 0.015g of aluminum powder, stir evenly, add 0.001g of aluminum powder Mix the waste engine oil and evenly coat the mold on the surface of the mold; put it in a constant temperature box at 50°C, let it stand for foaming for 25 minutes, and you can get a hollow cube with a length of 6cm, and maintain it at room temperature for 1 day to obtain a lightweight Constructed wetland special filler.

[0033] The phosphorus adsorption material made by the above process was used to carry out the phosphorus removal test of higher concentration sewage. The phosphorus content of raw sewage water is 30mg / l. Put 10g of the special filler for constructed wetland into a 300ml Erlenmeyer flask of domestic sewage, and the hydraulic retention time is 2 hours. After treatment, the concentration of phosphorus in the effluent was 4.6mg / l, and the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com