A preparation method of renewable modified shale ceramsite phosphorus removal filler

A shale ceramsite and modification technology, applied in chemical instruments and methods, biological water/sewage treatment, inorganic chemistry, etc., can solve the problems of low concentration phosphorus removal ability, poor regeneration, high preparation cost, and achieve good The effect of repeated use ability, strong phosphorus removal ability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

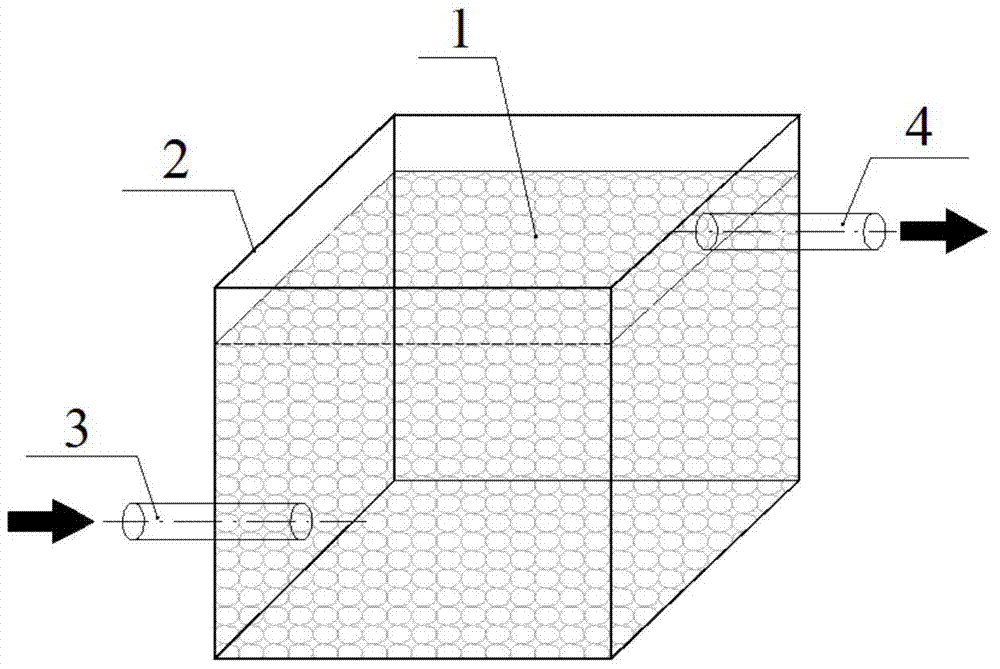

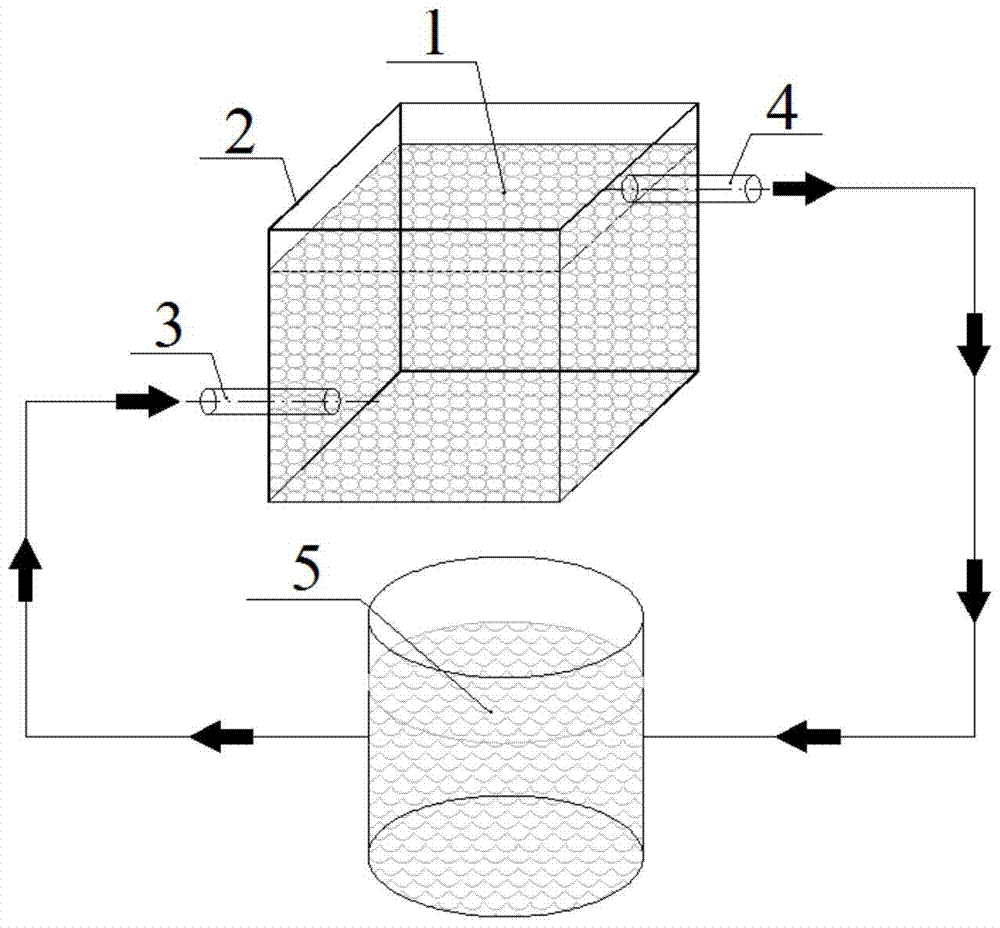

[0022] A preparation method for renewable modified shale ceramsite phosphorus removal filler, comprising the following steps:

[0023] Step 1. Soak shale ceramsite with a particle size of 4~6mm in 0.30~0.40mol / L HCl solution for 16~20h, wash with tap water first, and then wash with distilled or deionized water until the pH of the washing water is Neutral, then dry at 100~105°C for 8~10h to obtain dried shale ceramsite;

[0024] Step 2, ZnCl 2 , AlCl 3 , FeCl 3 According to the ratio of Zn:Al:Fe molar ratio of 1:(0.1~0.12):(0.35~0.40), the metal salt solution is prepared, and the Zn in the solution 2+ The concentration is 0.8~1.1mol / L;

[0025] Step 3. Slowly add the metal salt solution to the dried shale ceramsite, the volume ratio of the dried shale ceramsite to the metal salt solution is 1:(1~1.5); the mixing process is carried out at a temperature of 40±2°C , Oscillating at a vibration speed of 60~75r / min, and adjusting the pH value by adding NaOH solution with a conce...

Embodiment 2

[0033] A preparation method for renewable modified shale ceramsite phosphorus removal filler, comprising the following steps:

[0034] Step 1. Soak the shale ceramsite with a particle size of 6~8mm in 0.40~0.50mol / L HCl solution for 20~24h, wash it with tap water first, and then wash it with distilled water or deionized water until the pH of the washing water is Neutral, then dry at 105~110°C for 10~12h to obtain dried shale ceramsite;

[0035] Step 2, ZnCl 2 , AlCl 3 , FeCl 3 According to the ratio of Zn:Al:Fe molar ratio of 1:(0.12~0.15):(0.40~0.45), the ratio of Zn:Al:Fe to make metal salt solution, Zn in the solution 2+ The concentration is 1.1~1.5mol / L;

[0036] Step 3. Slowly add the metal salt solution to the dried shale ceramsite. The volume ratio of the dried shale ceramsite to the metal salt solution is 1:(1.5~2); the mixing process is carried out at a temperature of 40±2°C , Oscillate at a vibration speed of 75~90r / min, and adjust the pH value by adding NaOH so...

Embodiment 3

[0044] A preparation method for renewable modified shale ceramsite phosphorus removal filler, comprising the following steps:

[0045] Step 1. Soak the shale ceramsite with a particle size of 4~6mm in 0.35mol / L HCl solution for 18 hours, wash it with tap water first, and then wash it with distilled water or deionized water until the pH value of the washing water is neutral, then Dry at 105°C for 8 hours to obtain dried shale ceramsite;

[0046] Step 2, ZnCl 2 , AlCl 3 , FeCl 3 According to the ratio of Zn:Al:Fe molar ratio of 1:0.1:0.36, the metal salt solution is formulated, and the Zn in the solution 2+ The concentration is 0.85 / L;

[0047] Step 3. Slowly add the metal salt solution to the dried shale ceramsite. The volume ratio of the dried shale ceramsite to the metal salt solution is 1:1.2; Shake at a high speed, and adjust the pH value by adding NaOH solution with a concentration of 1.2mol / L, and keep the pH value stable at 10±0.2 during the whole process; after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com