Drilling mold for intermediate body inclined hole

A technology of inclined hole drilling jigs and intermediates, which is applied in the direction of drilling jigs, clamping, and supports for workpieces, which can solve the problems of inability to adjust the inclination of drilling jigs, high production costs, complexity and time-consuming, etc., and reduce reserves Quantity, improve production efficiency, avoid the effect of secondary disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

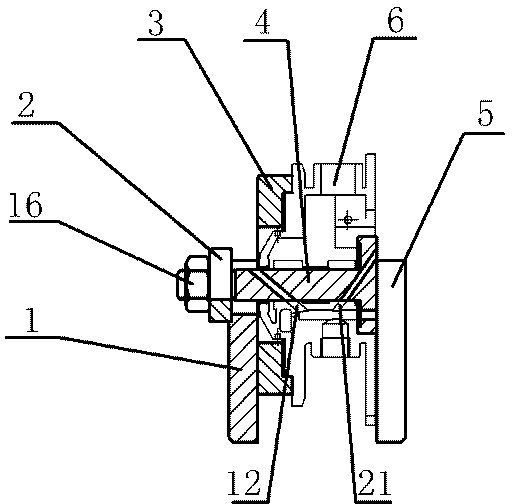

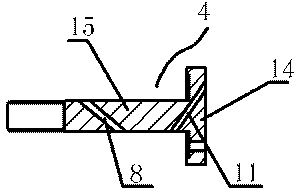

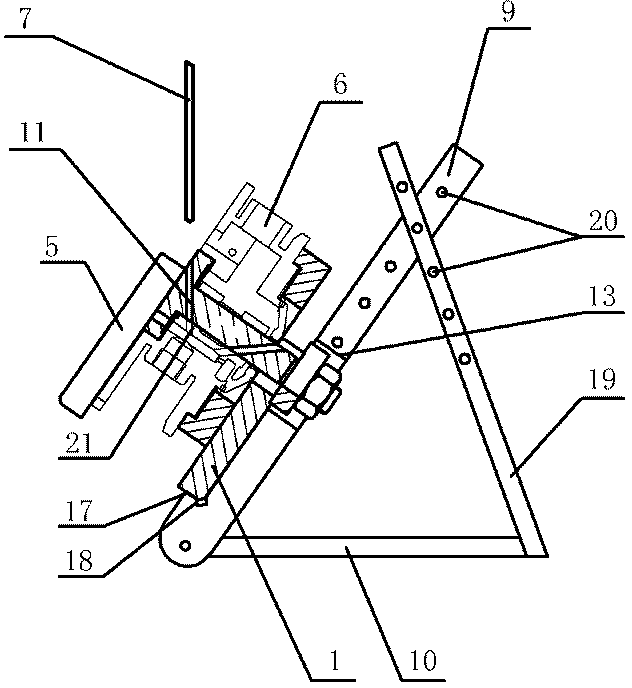

[0018] See figure 1 , figure 2 , image 3 and Figure 4 , an intermediate oblique hole drilling template, which includes a drilling template structure and an inclined plane fixing structure, the inclined plane fixing structure includes a fixing bracket and an inclined plate 9, the inclined plate 9 is obliquely installed on the fixing bracket, the drilling template structure is installed on the surface of the inclined plate 9, and the inclined plate 9 is equal to the included angle of the horizontal plane and the included angle of the drill form through hole and the horizontal plane; The positioning groove 18 in the direction is connected; the drilling mold structure includes a vortex end bottom plate 1, a pressure end bottom plate 5, a vortex end positioning ring 3 and a drilling mold rod 4, and the drilling mold rod 4 includes a transverse main part 15 and a longitudinal limiting part 14. The end bottom plate 1 is press-fitted on the outer surface of the vortex end positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com