Zirconia porcelain block for all-porcelain denture, and preparation process thereof

A technology of zirconia and stabilized zirconia, applied in the direction of additive processing, etc., can solve the problems of complex dyeing process, single overall color and light transmittance, and rigid changes in color and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

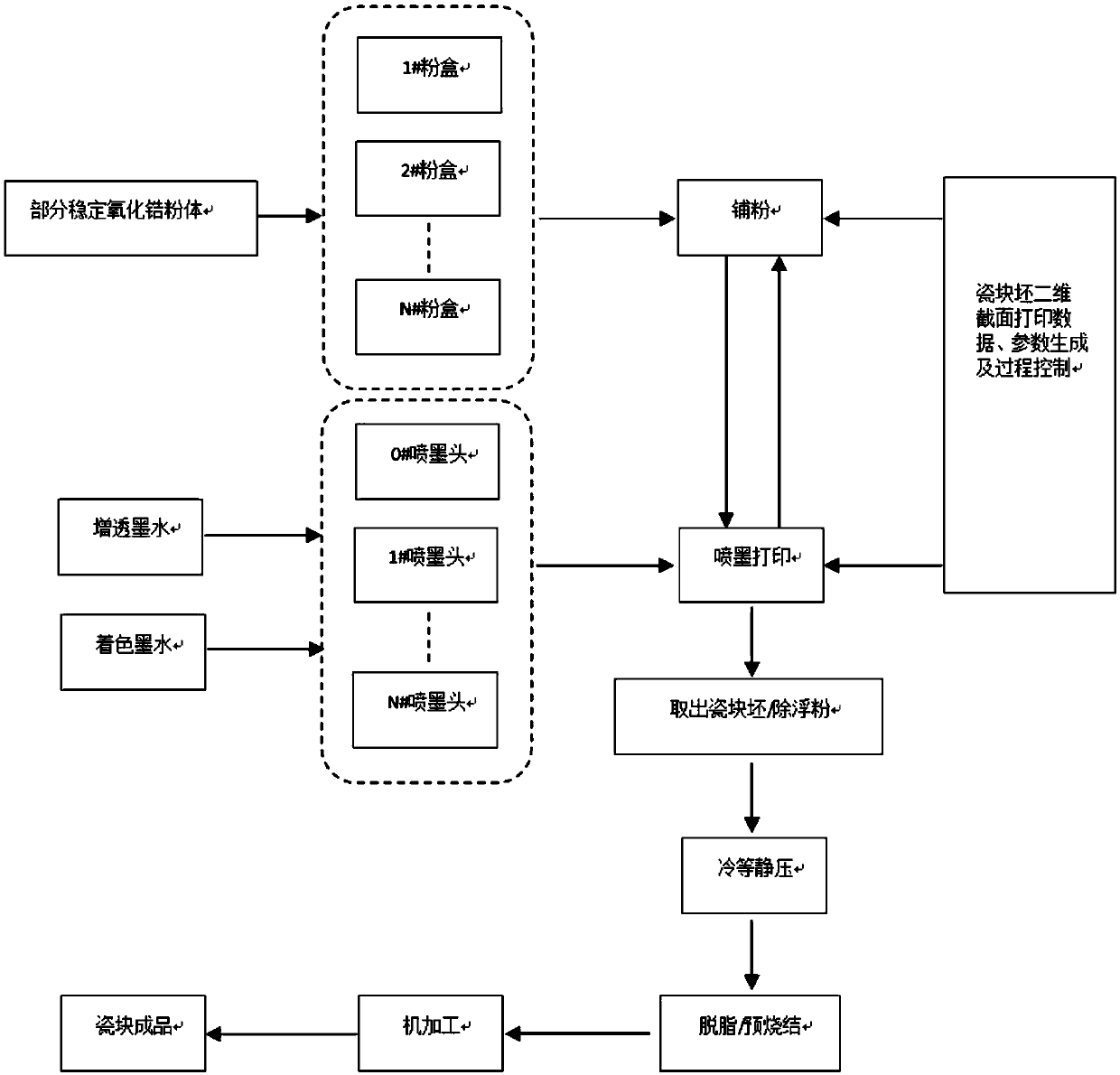

Method used

Image

Examples

Embodiment 1

[0069] Using 3mol% Y with particle sizes of 1-10 μm, 10-50 μm and 50-100 μm respectively 2 o 3 Partially stabilized zirconia spherical powder is mixed according to the volume ratio of 5, 22 and 73vol% to prepare a special mixed powder for inkjet printing with multi-level particle size distribution, and put it into the 1# powder box; The blank ink of oxide powder is loaded into the ink cartridge of 0# inkjet head; it contains 17700ppmY 3+ and 50ppmAl 3+ The ionic aqueous solution anti-reflection ink is loaded into the ink cartridge of the 1# inkjet head. According to the performance and specification requirements of zirconia blocks for all-ceramic dentures with quasi-continuous change in light transmittance, and considering the shrinkage of zirconia blocks after cold isostatic pressing and pre-firing, the diameter of zirconia blocks is set is 132mm, and the total thickness is 16.4mm; the thickness of a single layer of powder coating is 200μm (that is, a total of 82 layers ne...

Embodiment 2

[0072] Using 4mol% Y with particle sizes of 1-10 μm, 10-50 μm and 100-200 μm respectively 2 o 3 Partially stabilized zirconia spherical powder is mixed according to the volume ratio of 10, 25 and 65vol% to prepare a special mixed powder for inkjet printing with multi-level particle size distribution, and put it into the 1# powder box; The blank ink of oxide powder is packed in the ink cartridge of 0# ink-jet head; 3192ppmFe 3+ , 9.3ppmMn 3+ and 25047ppmEr 3+The ionic aqueous solution coloring ink is loaded into the ink cartridge of the 1# inkjet head. According to the performance and specification requirements of the zirconia block for all-ceramic dentures with quasi-continuous change in color (color saturation), and considering the shrinkage of the zirconia block body after cold isostatic pressing and pre-firing, the zirconia block is set The green body has a diameter of 132mm and a total thickness of 16.5mm; the thickness of a single layer of powder coating is 500μm (tha...

Embodiment 3

[0075] Using 3mol% Y with particle sizes of 0.01-0.1 μm, 1-10 μm and 10-50 μm respectively 2 o 3 Partially stabilized zirconia spherical powder is mixed according to the volume ratio of 7, 19 and 74vol% to prepare a special mixed powder for inkjet with multi-level particle size distribution, and put it into the 1# powder box; the metal-free and nano-metal oxidized The blank ink of substance powder is packed in the ink cartridge of 0# ink-jet head; Will contain 1.32%Y 2 o 3 , 0.02% MgO, 0.01% CaO, 0.005% TiO 2 and 0.005% Al 2 o 3 The aqueous suspension solution anti-reflection ink of nano-mixed powder is packed in the ink cartridge of 1# ink-jet head; 11350.3ppmFe 3+ , 22.8ppmMn 3+ and 18828ppmEr 3+ The ionic aqueous solution coloring ink is loaded into the ink cartridge of the 2# inkjet head. According to the performance and specification requirements of zirconia blocks for all-ceramic dentures with quasi-continuous changes in color and / or light transmittance, and cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com