Single-package dynamic air distributing device

A dynamic gas distribution, single-component technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of high-sensitivity instrument inspection interference, cumbersome operation, air leakage, etc., to reduce reserves and use, meet accurate calibration, Configure flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

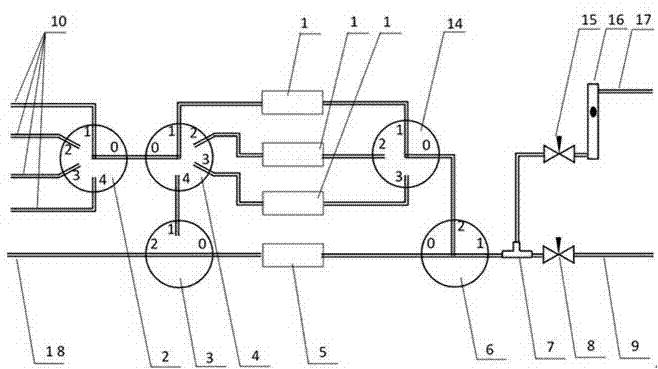

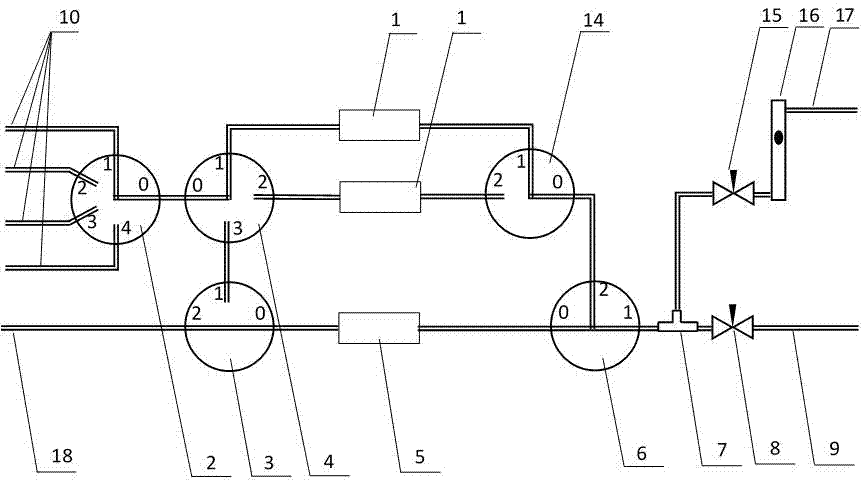

[0029] Such as figure 1 As shown, a single-component dynamic gas distribution device includes a feed gas mass flow controller 1, a dilution gas mass flow controller 5, a mixer 6, a feed gas access ball valve 4, and a feed gas output ball valve 14: wherein, the mixing The device 6 includes two inlets and an outlet for outputting standard gas; the inlet of the dilution gas mass flow controller 5 is connected to the dilution gas inlet 18, and the dilution gas is inserted, and the outlet is connected to an inlet of the mixer 6 to form a dilution gas path; raw material The number of gas mass flow controllers 1 is at least 2, and the measuring range increases proportionally, and the common ratio of the proportional growth is not less than 5, that is, if two raw gas mass flow controllers 1 are used, the second raw gas mass flow controller The measuring range of the first device 1 is n times of the first one; if three are used, the measuring range of the third one is n times of the se...

Embodiment 2

[0032] On the basis of Embodiment 1, the single-component dynamic gas distribution device in this embodiment also includes a diluent gas access ball valve 3, and the diluent gas access ball valve 3 is an L-shaped three-way ball valve, including two inlets and a outlet, the outlet of which is connected to the inlet of the dilution gas mass flow controller 5, and one of its inlets is connected to the dilution gas; in addition, the number of outlets of the feed gas connected to the ball valve 4 is greater than the number of feed gas mass flow controllers 1, so that the feed gas The outlet of the ball valve 4 is connected to the outlet of the raw material gas mass flow controller 1, and there is one outlet left, which is connected to the other inlet of the L-shaped three-way ball valve. The L-type three-way ball valve is used to select the gas flowing through the dilution gas mass flow controller 5. The L-type three-way ball valve 3 is switched to No. 2 port, and when the raw mater...

Embodiment 3

[0034] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that the quantity of the above-mentioned feed gas mass flow controllers 1 is three, wherein the range of the second feed gas mass flow controller 1 is the first feed gas mass flow controller 1 Gas mass flow controller 1 is 10 times, the third raw gas mass flow controller 1 is 10 times that of the second raw gas mass flow controller 1, that is, the measuring range increases by a common ratio of 10, and the dilution gas mass flow controller 5 is a mass flow controller with a large range, and its measuring range is generally more than twice the largest measuring range of the raw material gas mass flow controller 1, specifically: the measuring ranges of the three raw material gas mass flow controllers 1 are: 5mL / min, control flow range (0.5-5) mL / min; 50mL / min, control flow range (5-50) mL / min; 500mL / min, control flow range (50-500) mL / min; dilution gas mass flow rate The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com