Parallel flow heat exchanger and use

An exchanger, parallel flow technology, used in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problem of increasing the volume of parallel flow heat exchangers, uneven distribution of gas and liquid, and unsatisfactory effects, etc. It can improve the heat exchange efficiency, improve the heat exchange medium, and solve the problem of uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

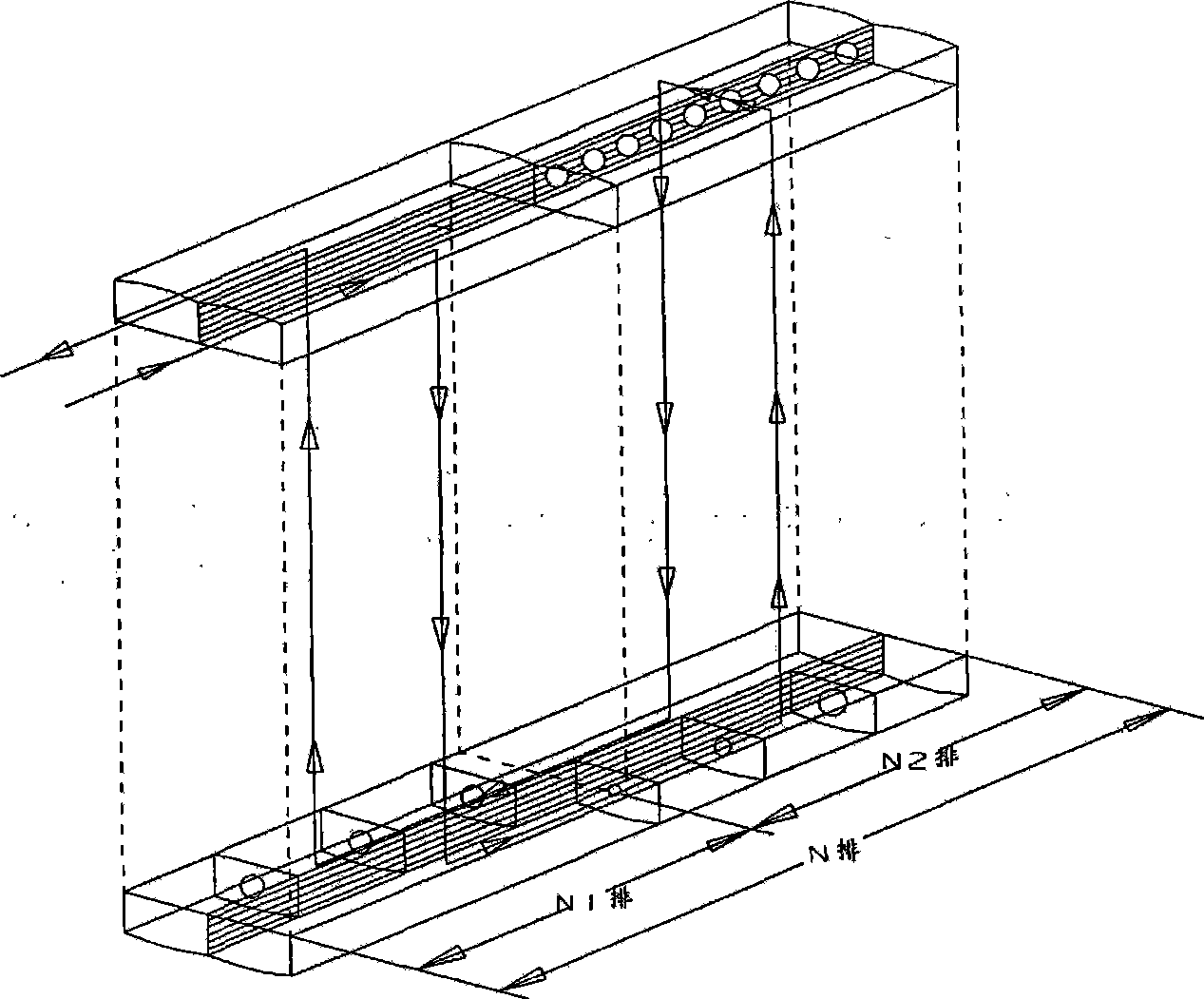

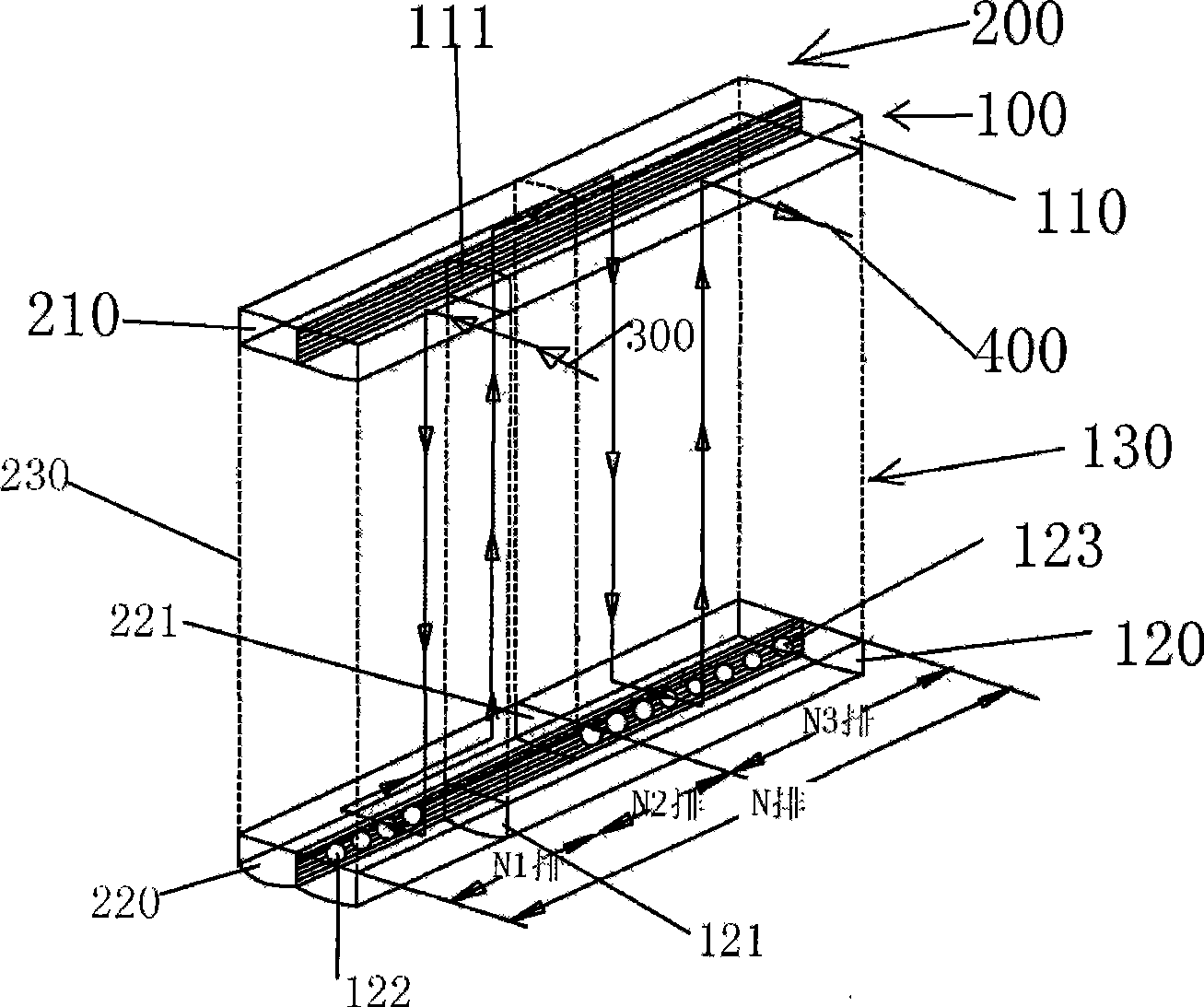

[0036] Such as image 3 The parallel flow heat exchanger shown is an evaporator used in an automobile. It includes two parallel flow heat exchanger units stacked together for ease of description and is defined as a first parallel flow heat exchange unit 100 and a second parallel flow heat exchange unit 200.

[0037] The first parallel flow heat exchange unit 100 includes a top header 110, a bottom header 120, and several parallel arranged flat tubes 130 connecting the top header 110 and the bottom header 120. The shape of the flat tubes 130 is the same as that of the present application. The Chinese invention patent "an aluminum extruded thin-wall profile" filed on April 21, 2006, has an application number of 200610025898.3 and an announcement number of CN1967135, which will not be described in detail here.

[0038] The second parallel flow heat exchange unit 200 includes a top header 210, a bottom header 220, and several parallelly arranged flat tubes 230 connecting the top header...

Embodiment 2

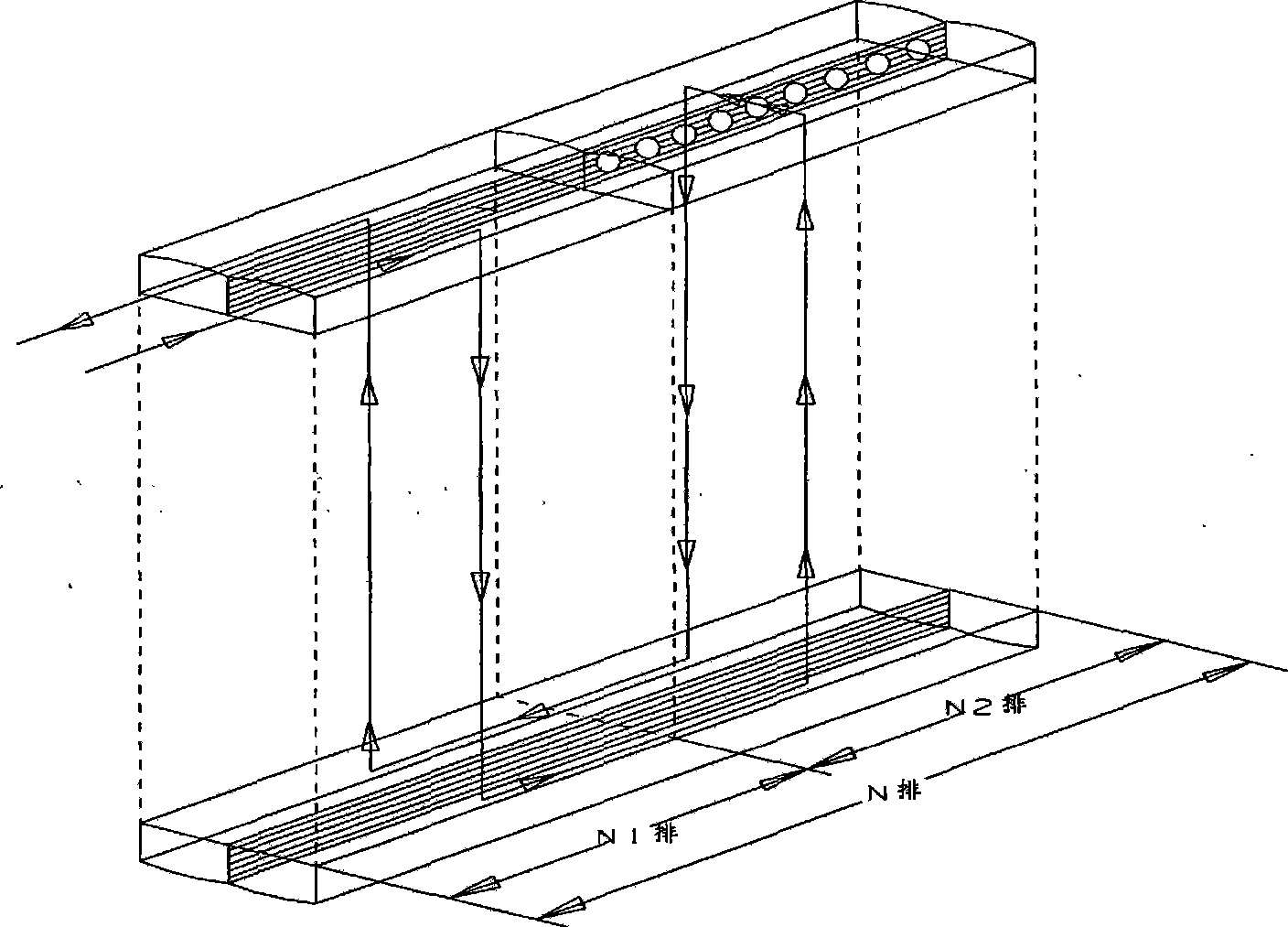

[0043] Such as Figure 4 The parallel flow heat exchanger shown is an evaporator used in an automobile. It includes two parallel flow heat exchanger units stacked together for ease of description and is defined as a first parallel flow heat exchange unit 100 and a second parallel flow heat exchange unit 200.

[0044] The first parallel flow heat exchange unit 100 includes a top header 110, a bottom header 120, and a plurality of parallel arranged flat tubes 130 connecting the top header 110 and the bottom header 120. The shape of the flat tubes 130 is the same as the embodiment. 1.

[0045] The second parallel flow heat exchange unit 200 includes a top header 210, a bottom header 220, a draft tube 240, and several parallel arranged flat tubes 230 and a flat tube 130 connecting the top header 210 and the bottom header 220. The shape is the same as in Example 1. The flat tubes 230 and 130 can be connected as a whole as described in the invention with the application number 200610025...

Embodiment 3

[0055] Such as Figure 5 Parallel flow heat exchanger shown. It includes three parallel flow heat exchanger units stacked together for ease of description, and is defined as a first parallel flow heat exchange unit 100, a second parallel flow heat exchange unit 200, and a third parallel flow heat exchange unit 500.

[0056] The first parallel flow heat exchange unit 100 includes a top header 110, a bottom header 120, and a plurality of parallel arranged flat tubes 130 connecting the top header 110 and the bottom header 120. The shape of the flat tubes 130 is the same as the embodiment. 1.

[0057] The second parallel flow heat exchange unit 200 includes a top header 210, a bottom header 220, and several parallelly arranged flat tubes 230 connecting the top header 210 and the bottom header 220. The shape of the flat tubes 230 is the same as the embodiment 1.

[0058] The third parallel flow heat exchange unit 500 includes a top header 510, a bottom header 520, and several parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com