High-dispersion impact-resistance graphene antiseptic coating and preparation method

An anti-corrosion coating and graphene technology, applied in the field of coatings, can solve problems such as mechanical properties, anti-corrosion performance degradation, coating film stress concentration, agglomeration, etc., to achieve the effect of improving anti-corrosion performance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation of graphene anti-corrosion coating

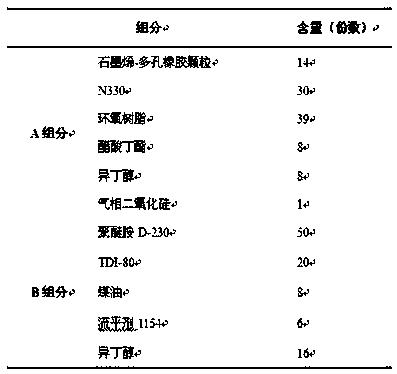

[0042] A component:

[0043] (1) At room temperature, put graphene and AC foaming agent at a ratio of 10:1 into a stirring container and stir until uniform to obtain graphene mixed powder.

[0044] (2) Put a sufficient amount of graphene mixed powder and porous rubber particles into a stirring container, and stir in the airtight container at a high speed. During the stirring process, it is heated to 50°C and kept at a constant temperature until the holes of the rubber particles are filled with graphene mixed powder. , separated by a solid sieve to remove excess graphene mixed powder.

[0045](3) Add resin, solvent, and anti-sedimentation agent into the mixing vessel, stir at a high speed of 1500r / min, add rubber particles loaded with graphene mixed powder while stirring, heat the water bath to 80°C and stir for 2 hours at a constant temperature.

[0046] (4) Grind the components prepared above with a grinder, and then f...

Embodiment 1

[0051]

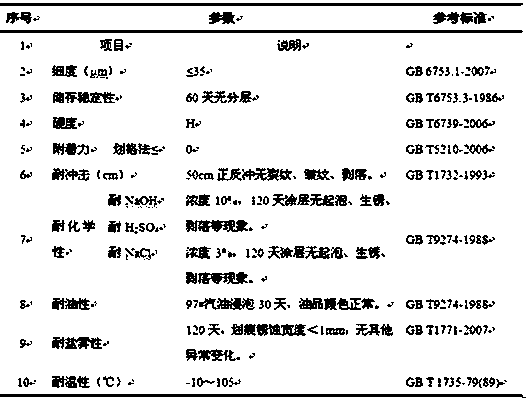

[0052] The performance parameters of the coating prepared by AB component according to 100:12.5 are shown in the following table:

[0053]

Embodiment 2

[0055]

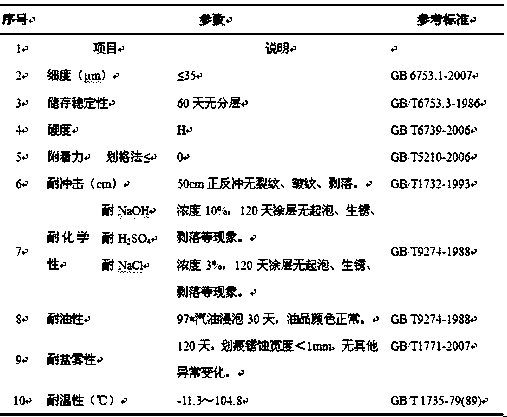

[0056] The performance parameters of the coating obtained by preparing AB components at a ratio of 100:13 are shown in the following table:

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com