Composite feed pipe of packed tower

A technology of feeding pipe and packed tower, applied in the field of packed tower, can solve the problem of uneven distribution of liquid, and achieve the effects of uniform discharge distribution, good rigidity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

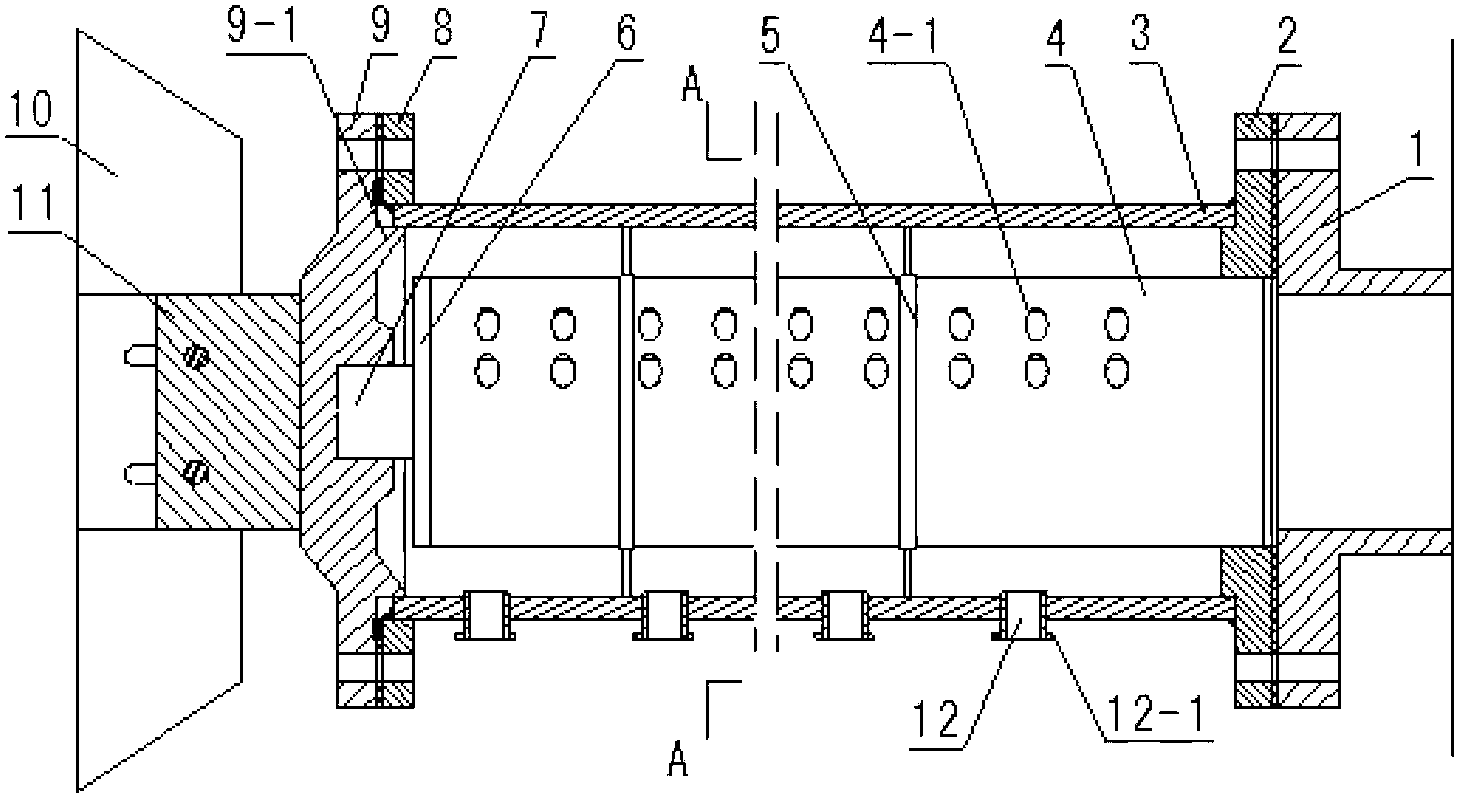

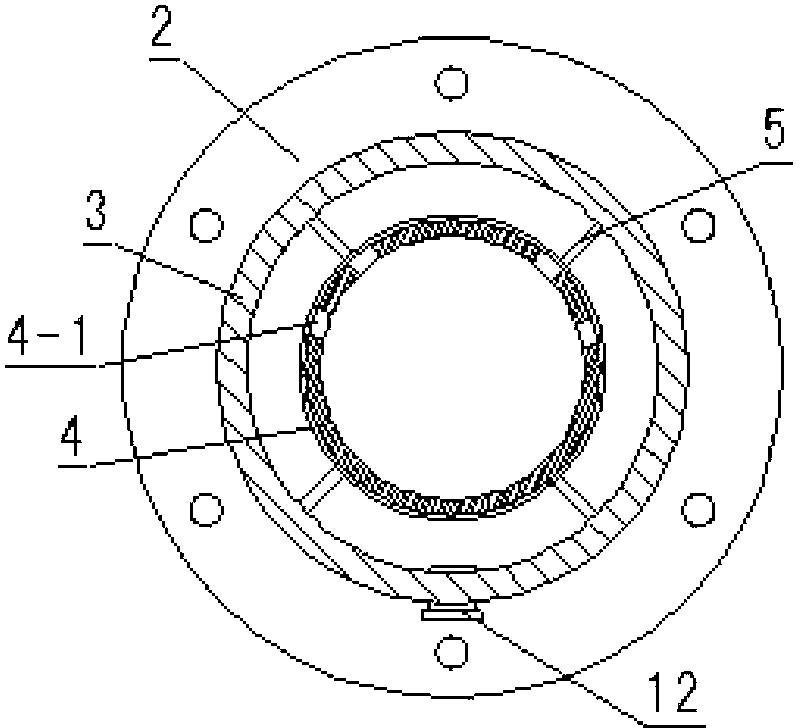

[0024] One end of the inner pipe 4 in Embodiment 1 can be seamlessly welded or screwed to the inner side of the center hole of the first flange 2 .

[0025] The closed connection between one end of the outer tube 3 and the first flange 2 in Embodiment 1 is that the end of the outer tube is sleeved on the central hole boss of the first flange 2, and the end of the outer tube is connected to the first flange along the first flange. The end face of the blue plate is seamlessly welded.

[0026] In Embodiment 1, one end of the inner tube fixed to the first flange 2 is provided with a sealing plate 6 at the other end, and the center of the sealing plate is provided with a support column 7 that enables the inner tube to be supported on the non-porous flange, and the non-porous flange 9 A blind hole corresponding to the support column is provided.

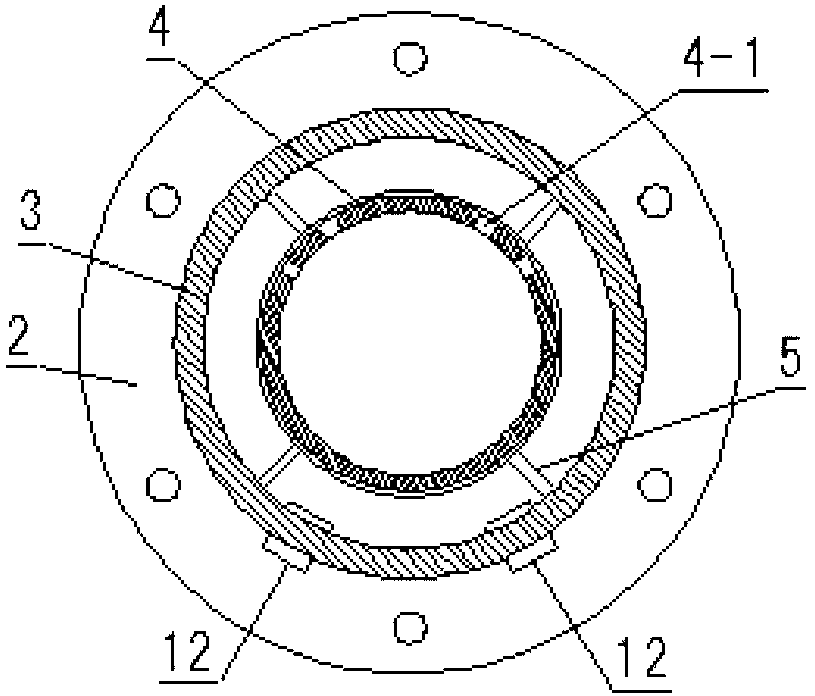

[0027] In Embodiment 1, the other end of the outer tube 3 is fixed to the second flange 8, that is, the end of the outer tube 3 is engag...

Embodiment 2

[0033] The liquid outlet pipe 12 of embodiment 2 can also be symmetrically arranged in multiple rows, and it is suitable for a packed tower with a larger liquid output, and the liquid output of the inner pipe 4 corresponding thereto should be greater than the liquid output of the outer pipe 3 of embodiment 2, That is, the diameter of the liquid outlet hole 4-1 of the inner tube 4 can be increased or the number of the liquid outlet hole 4-1 can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com