Disc type drying machine

A dryer and disc-type technology, which is applied in the direction of dryers, drying, and drying solid materials, etc., can solve the problems of uneven heat absorption of materials, small contact area, and affecting the drying effect of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

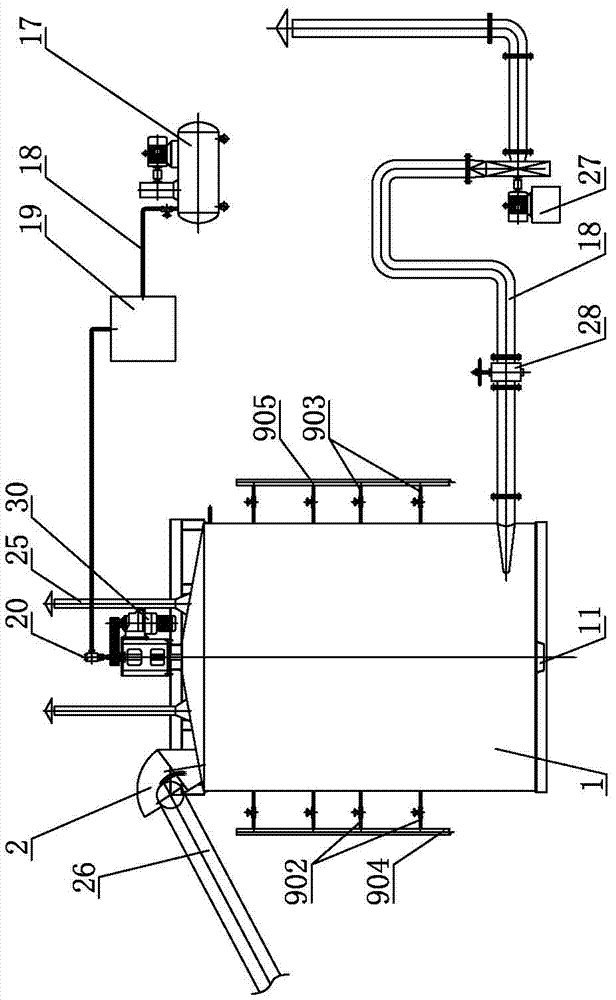

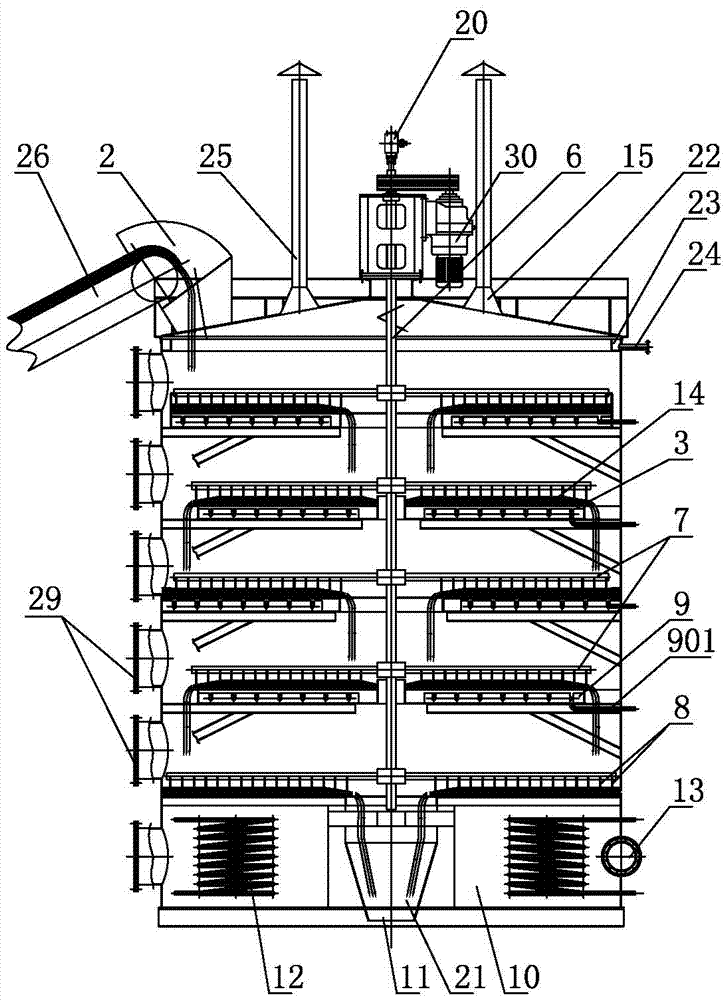

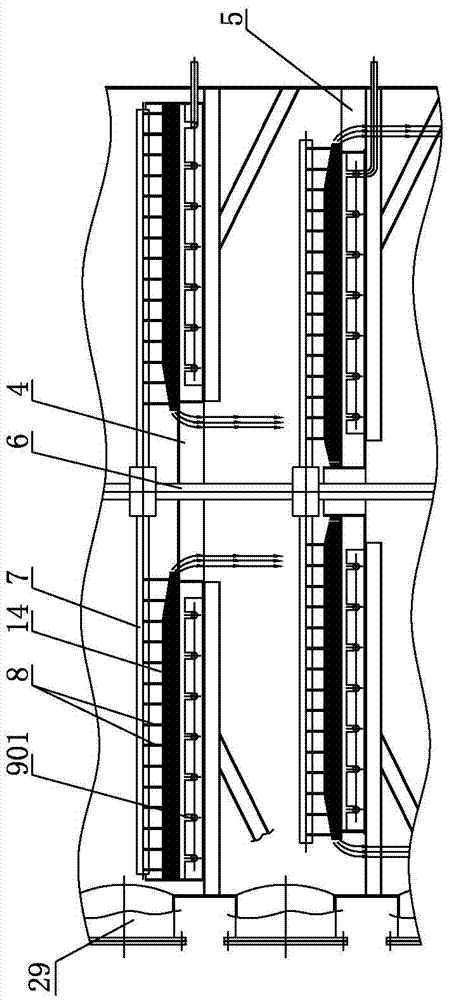

[0024] Such as Figure 1-8As shown, it is a disc dryer, which includes a vertical cylinder body 1, the top of the cylinder body 1 is provided with a feed port 2, and several layers of trays 3 are arranged at intervals from top to bottom inside the cylinder body 1. The number of trays 3 is an odd number, and the middle part of the trays 3 located in the odd layers is provided with a blanking hole 4, and an annular blanking channel 5 is left between the outer peripheral edge of the trays 3 located in the even layers and the inner wall of the cylinder body 1. A rotating shaft 6 connected to the rotating drive mechanism 30 is arranged in the axial direction of the body 1, and several groups of scraping mechanisms are arranged on the rotating shaft 6 corresponding to each supporting tray 3 in the axial direction. The swing bracket 7 distributed radially in the circumferential direction, on the swing bracket 7, a number of scrapers 8 are respectively provided corresponding to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com