Preparation method of negative ion health-care fabric

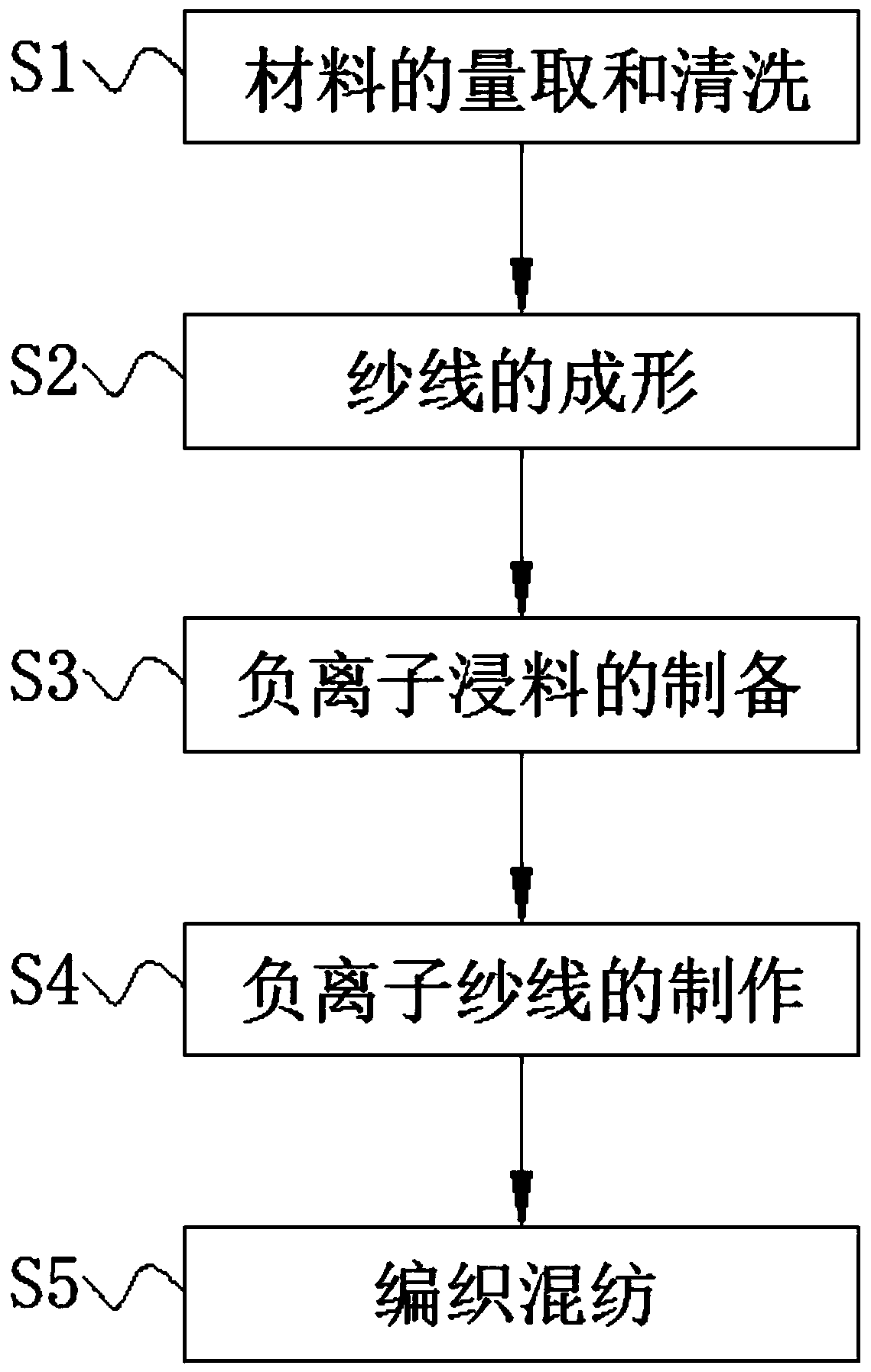

A technology of health-care fabrics and negative ions, which is applied in the field of preparation of negative-ion health-care fabrics, and can solve the problems of shortening the duration of health-care effects of negative-ion fabrics, the inability to realize negative-ion treatment of woven yarns, and the shedding of negative-ion coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1, measuring and cleaning of materials: First, measure 25 parts of natural fiber, 15 parts of modal fiber, 15 parts of spandex fiber, 7 parts of nylon fiber, 7 parts of regenerated cellulose fiber and 7 parts of acetate fiber materials, and the measured components are cleaned twice through the cleaning equipment through the fiber materials in order to clean the impurities and fluff on the surface of each fiber. The natural fibers are soybean fiber, kapok fiber and abaca fiber Combination fiber material with ramie fiber;

[0025] S2. Shaping of yarn: Dry the fiber materials after step S1 is cleaned by hot air drying equipment for 25 minutes, so that the moisture on the surface of each fiber material is fully evaporated, and then dry the natural fiber and modal fiber , spandex fiber, nylon fiber, regenerated cellulose fiber and acetate fiber are sequentially passed through the yarn forming equipment to make natural fiber yarn, modal fiber yarn, spandex fiber yarn, nylon ...

Embodiment 2

[0030] S1, measuring and cleaning of materials: First, measure 20 parts of natural fiber, 10 parts of modal fiber, 10 parts of spandex fiber, 5 parts of nylon fiber, 5 parts of regenerated cellulose fiber and 5 parts of cellulose acetate material, and each component measured is washed 2 times through the cleaning equipment successively through the fiber material, so that the impurities and fluff on the surface of each fiber are cleaned out, and the natural fiber is soybean fiber;

[0031] S2. Shaping of yarn: Dry the fiber materials after step S1 is cleaned by hot air drying equipment for 20 minutes, so that the moisture on the surface of each fiber material is fully evaporated, and then dry the natural fiber and modal fiber , spandex fiber, nylon fiber, regenerated cellulose fiber and acetate fiber are sequentially passed through the yarn forming equipment to make natural fiber yarn, modal fiber yarn, spandex fiber yarn, nylon fiber yarn, regenerated cellulose fiber yarn and a...

Embodiment 3

[0036] S1. Material measurement and cleaning: First, measure 30 parts of natural fiber, 20 parts of modal fiber, 20 parts of spandex fiber, 10 parts of nylon fiber, 10 parts of regenerated cellulose fiber and 10 parts of cellulose acetate material, and each component measured by fiber material is cleaned 3 times by cleaning equipment successively, and the impurity and fluff on each fiber surface are cleaned out, and natural fiber is ramie fiber;

[0037] S2. Shaping of yarn: Dry the fiber materials after step S1 is cleaned by hot air drying equipment for 30 minutes, so that the moisture on the surface of each fiber material is fully evaporated, and then dry the natural fiber and modal fiber , spandex fiber, nylon fiber, regenerated cellulose fiber and acetate fiber are sequentially passed through the yarn forming equipment to make natural fiber yarn, modal fiber yarn, spandex fiber yarn, nylon fiber yarn, regenerated cellulose fiber yarn and acetate fiber For fiber yarn, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com