Porous ceramic heating element used for electronic cigarette and preparation method of porous ceramic heating element

A technology of porous ceramics and heating body, which is applied in the direction of smoker's products, applications, tobacco, etc., can solve the problems of affecting the uniformity of heating, such as the taste of electronic cigarettes, and achieve the effects of simple structure, sufficient vaporization of e-liquid, and guaranteed use strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

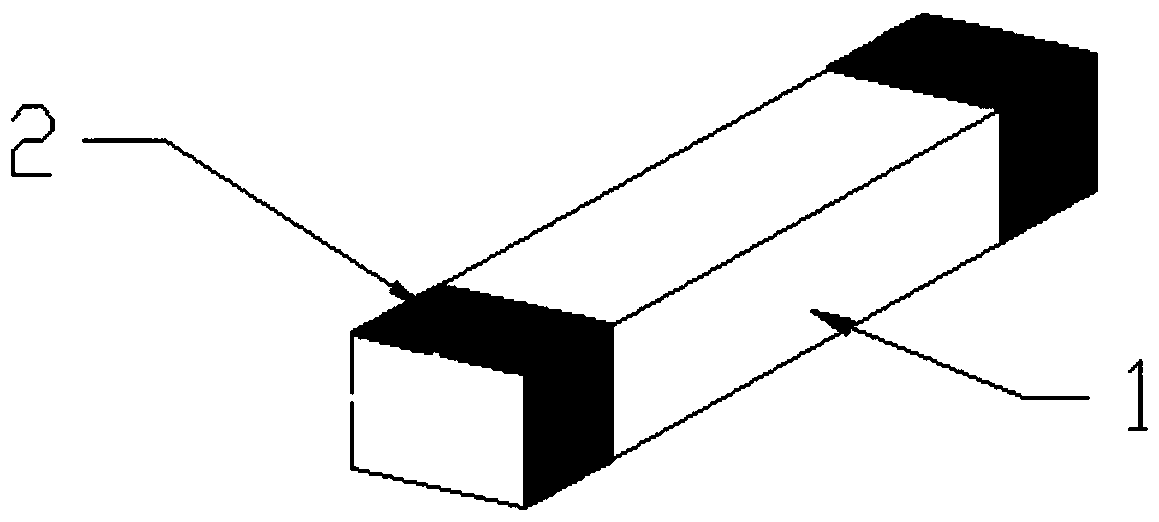

[0030] see figure 1 , the preparation method of the porous ceramic heating element for electronic cigarettes in Example 1 is that the electrodes 2 are respectively welded to the surfaces of both ends of the porous ceramic substrate 1 .

[0031] The electrode 2 is formed by sintering a silver-containing metal layer at 800° C., specifically silver palladium, silver ruthenium or silver platinum.

[0032] And the porous ceramic substrate of embodiment 1 is prepared by the following method, comprises steps:

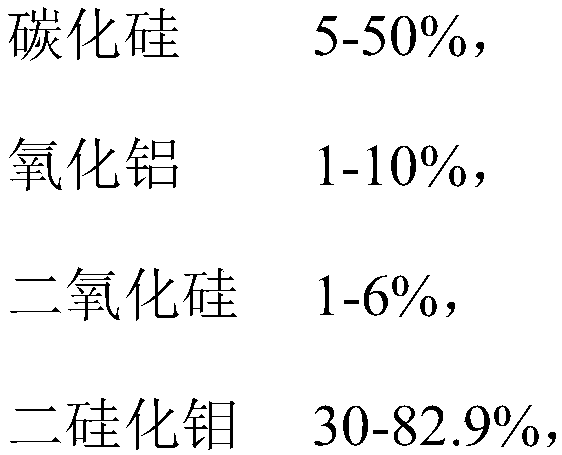

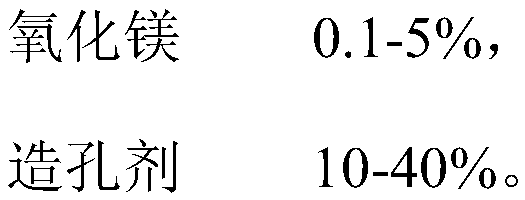

[0033] S1. According to the mass fraction, the raw materials of the porous ceramic matrix are ball milled and mixed, and the raw materials include:

[0034]

[0035] Wherein, the pore-forming agent is starch;

[0036] S2. The mixed raw materials are molded by hot die casting, adding paraffin wax of 60% of the total mass of the raw materials, the temperature of the hot die casting barrel is 50°C, the temperature of the discharge port is 80°C, and the pressure is 0.2Mpa t...

Embodiment 2

[0041] The preparation method of the porous ceramic heating element for electronic cigarettes in Example 2 is that the electrodes 2 are respectively welded to the surfaces of both ends of the porous ceramic substrate 1 .

[0042] The electrode 2 of the embodiment 2 is formed by sintering the silver-containing metal layer at 1200°C.

[0043] And the porous ceramic substrate of embodiment 2 is prepared by the following method, comprises steps:

[0044] S1. According to the mass fraction, the raw materials of the porous ceramic matrix are ball milled and mixed, and the raw materials include:

[0045]

[0046] Wherein, the pore forming agent is graphite;

[0047] S2. The mixed raw materials are molded by hot die casting, adding 30% paraffin wax to the total mass of the raw materials, the temperature of the hot die casting barrel is 70°C, the temperature of the discharge port is 60°C, and the pressure is 6Mpa to obtain a green body;

[0048] S3, drying the green body at room...

Embodiment 3

[0052] The preparation method of the porous ceramic heating element for electronic cigarettes in Example 3 is that the electrodes 2 are respectively welded to the surfaces of both ends of the porous ceramic substrate 1 .

[0053] The electrode 2 of the embodiment 3 is formed by sintering the silver-containing metal layer at 900°C.

[0054] And the porous ceramic substrate of embodiment 3 is prepared by the following method, comprises steps:

[0055] S1. According to the mass fraction, the raw materials of the porous ceramic matrix are ball milled and mixed, and the raw materials include:

[0056]

[0057] Wherein, the pore-forming agent is cellulose;

[0058] S2. The mixed raw materials are formed by dry pressing, and 15% PVA is added to the total mass of the raw materials of the porous ceramic matrix, and the pressure is 5Mpa to obtain a green body;

[0059] S3, drying the green body at room temperature, and then drying in an oven;

[0060] S4. Move the dried body int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com