Sample preparation method of scanning electron microscope of basalt fiber and asphalt mixed material fracture

An asphalt mixture and basalt fiber technology, which is applied in the preparation of test samples and material analysis using measurement of secondary emissions, can solve the problem that the distribution of basalt fibers cannot comprehensively reflect the microstructural characteristics of the fracture surface, and the unfavorable scanning Surface electron microscope observation and comparative analysis, different sample sizes and shapes, etc., to achieve the effect of uniform size, regular shape and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

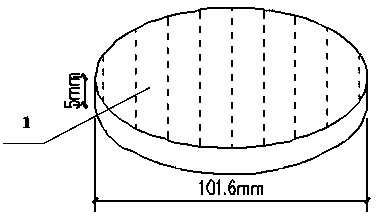

[0028] (1) Marshall specimens of asphalt mixture mixed with basalt fiber were prepared by Marshall standard compaction method. The specimen was cylindrical, with a diameter of 101.6mm and a height of 63.5mm.

[0029] (2) Due to the large size of the Marshall specimen and the small size of the scanning electron microscope sample chamber, it is necessary to obtain a small-sized basalt fiber asphalt mixture sample first, and use a high-precision cutting instrument to cut the Marshall specimen into 5mm thick round flakes, such as figure 1 shown.

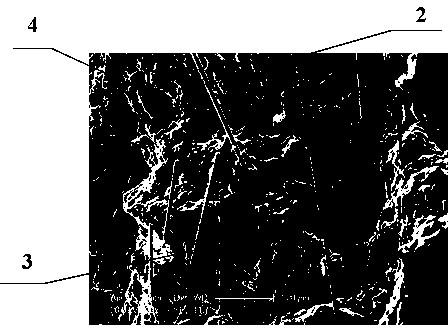

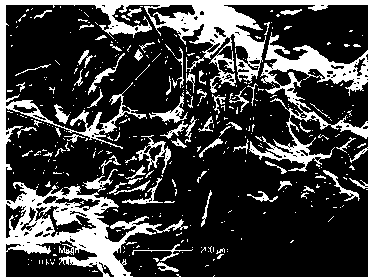

[0030] (3) Fine cutting: use a high-precision cutting instrument along the figure 1 Cut the asphalt mixture circular thin slice equidistantly in the direction of the middle dotted line, and then cut off the arc parts at both ends of the strip sample to obtain a basalt fiber asphalt mixture strip sample with a length of 30mm, a width of 12mm, and a height of 5mm. like figure 2 shown.

[0031] (4) Use a high-precision cutting instru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com