Tobacco filler for non-combustion type heat smoking article

a non-combustion type, filler technology, applied in the direction of tobacco, tobacco manufacturing, tobacco treatment, etc., can solve the problem of liable to volatilize in the oral cavity, and achieve the effect of reducing the so-called “inhibition of flavor tasting” and sufficient evaporation of flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0079]The present invention is more specifically described hereinafter by way of Examples. The present invention may be appropriately modified within the scope of the present invention.

examples 1 and 2

and Comparative Examples 1 to 7: Verification of an Effect by Variation in Aerosol Generating Liquids

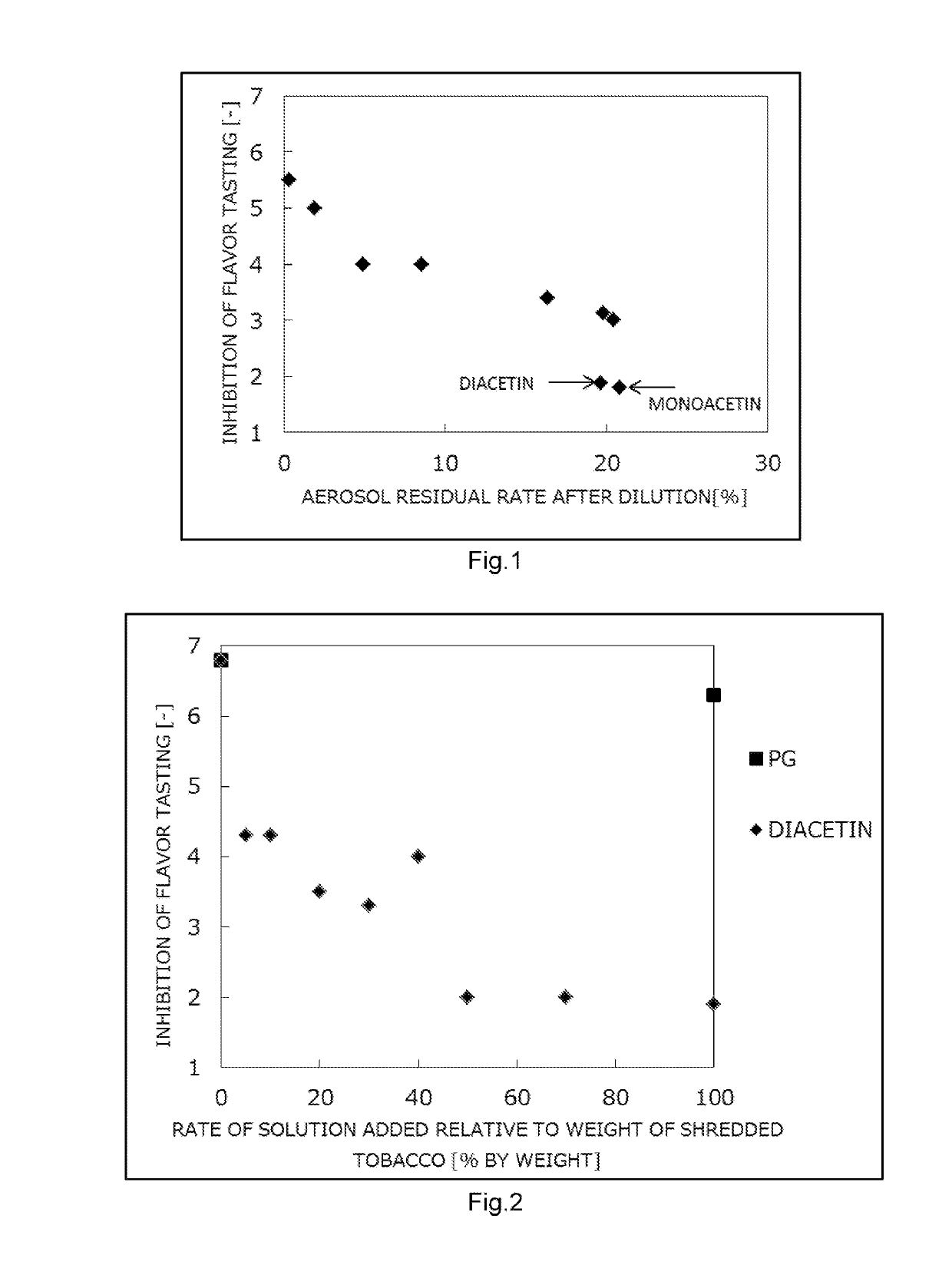

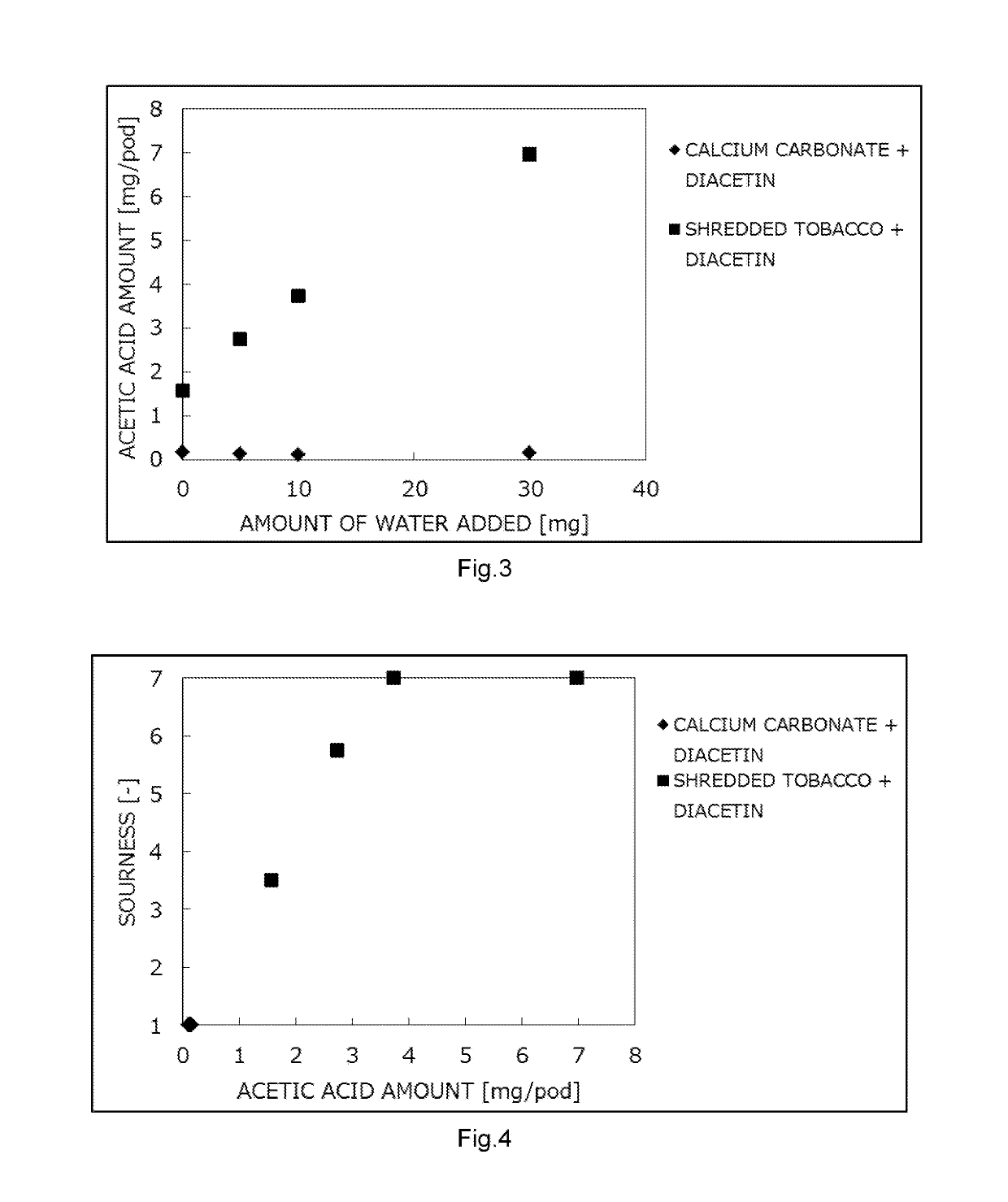

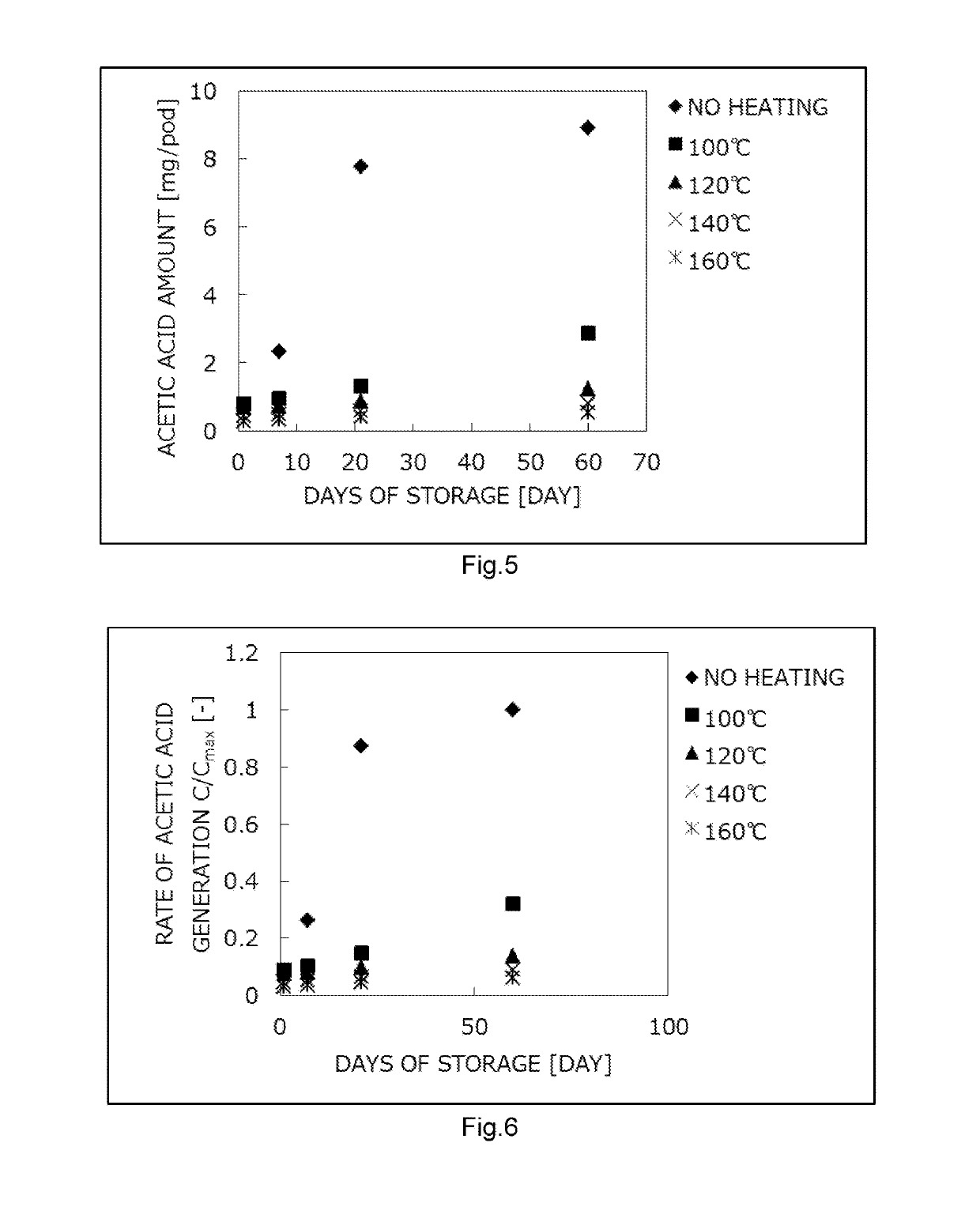

[0080]In order to verify an effect of variation of aerosol generating liquids on a reduction of inhibition of flavor tasting, 100 mg of various aerosol generating liquids indicated in Table 1 were respectively added to 100 mg of shredded flue-cured tobacco (product in Japan, hereinafter also merely referred to as shredded tobacco; acetic acid generation rate constant: 1.17×10−8 s−1) as in Example 5 hereinafter as the tobacco material to prepare samples.

[0081]Shredded tobacco used was obtained by grinding tobacco in a household mixer followed by shaking on a sieve (AS 200, manufactured by Retsch GmbH) under the condition: amplitude-1.5 mm / “g” for 2 minutes, and had a mesh size of 0.5 mm or less. The prepared samples were respectively added to a pod dedicated to a product with the product name “Ploom” marketed by Japan Tobacco Inc. so as to be attached to the pod, and stored for 2 days...

examples 2 to 4

and Comparative Examples 8 to 14 Study on the Amount that is Effective for Reduction of Inhibition of Flavor Tasting

[0087]As described above, diacetin and monoacetin are respectively difficult to be isolated, and thus solutions containing diacetin and monoacetin have very similar compositions. Thus, in the following Examples, a solution containing diacetin (commercially available product) was used as a typical example for studying the amount that was effective for reduction of inhibition of flavor tasting.

[0088]In order to study the amount that was effective for reduction of inhibition of flavor tasting, to 100 mg of shredded Burley tobacco (product in Japan), diacetin and, as a comparison, propylene glycol were respectively added at the amounts indicated in Table 2 to prepare samples. The samples were prepared in the same manner as previous Examples and stored for 2 days or more under the conditions of 22° C. and humidity of 60%. The sensory evaluation of the prepared samples was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com