Evaporative condensing and cooling device

An evaporative condensation and evaporative cooling technology, which is applied in the direction of fixed conduit components, heat exchanger types, lighting and heating equipment, etc., can solve the problems of water mist environment, pollution, etc., to reduce the air velocity and eliminate the growth of Legionella Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

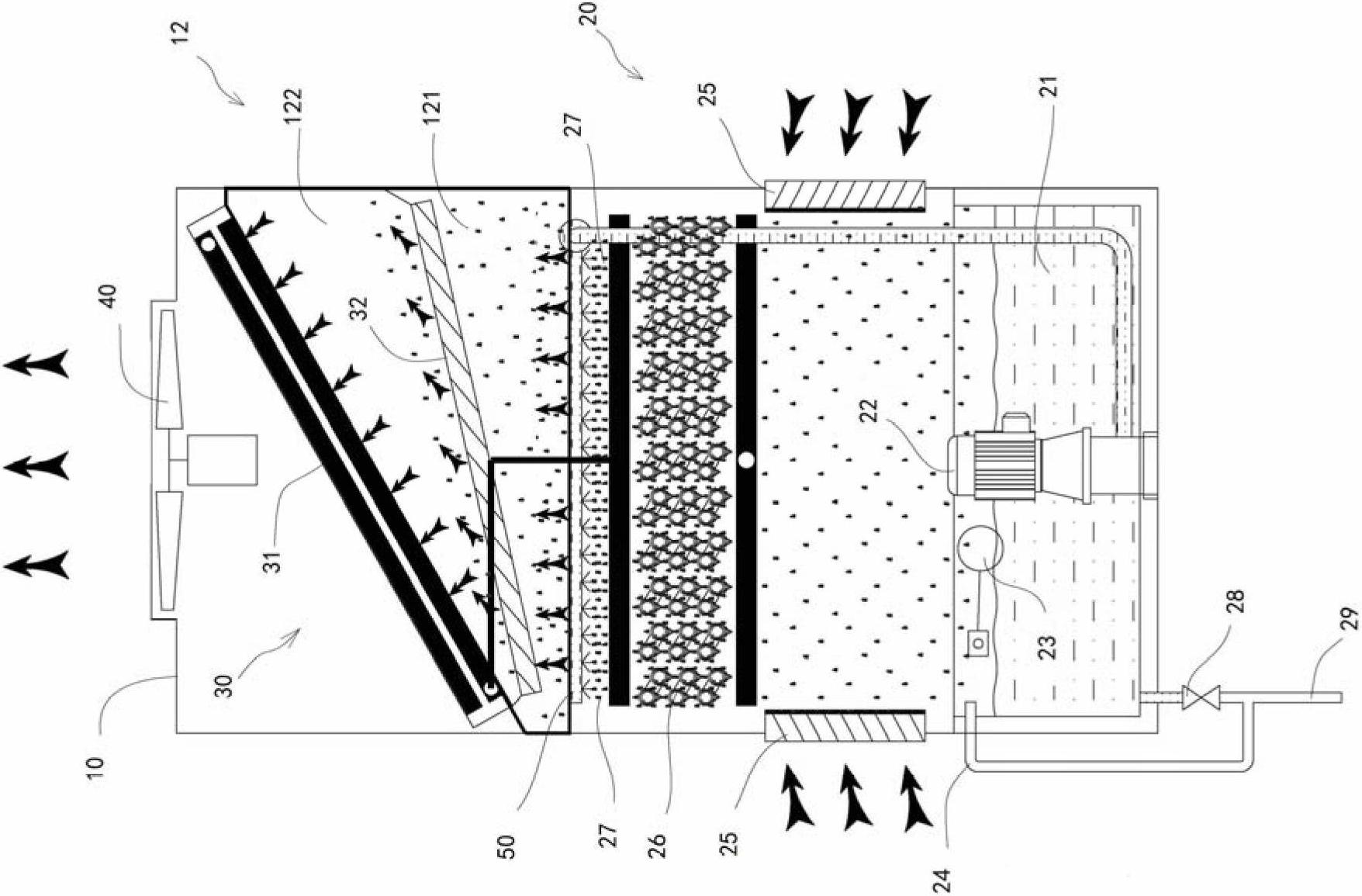

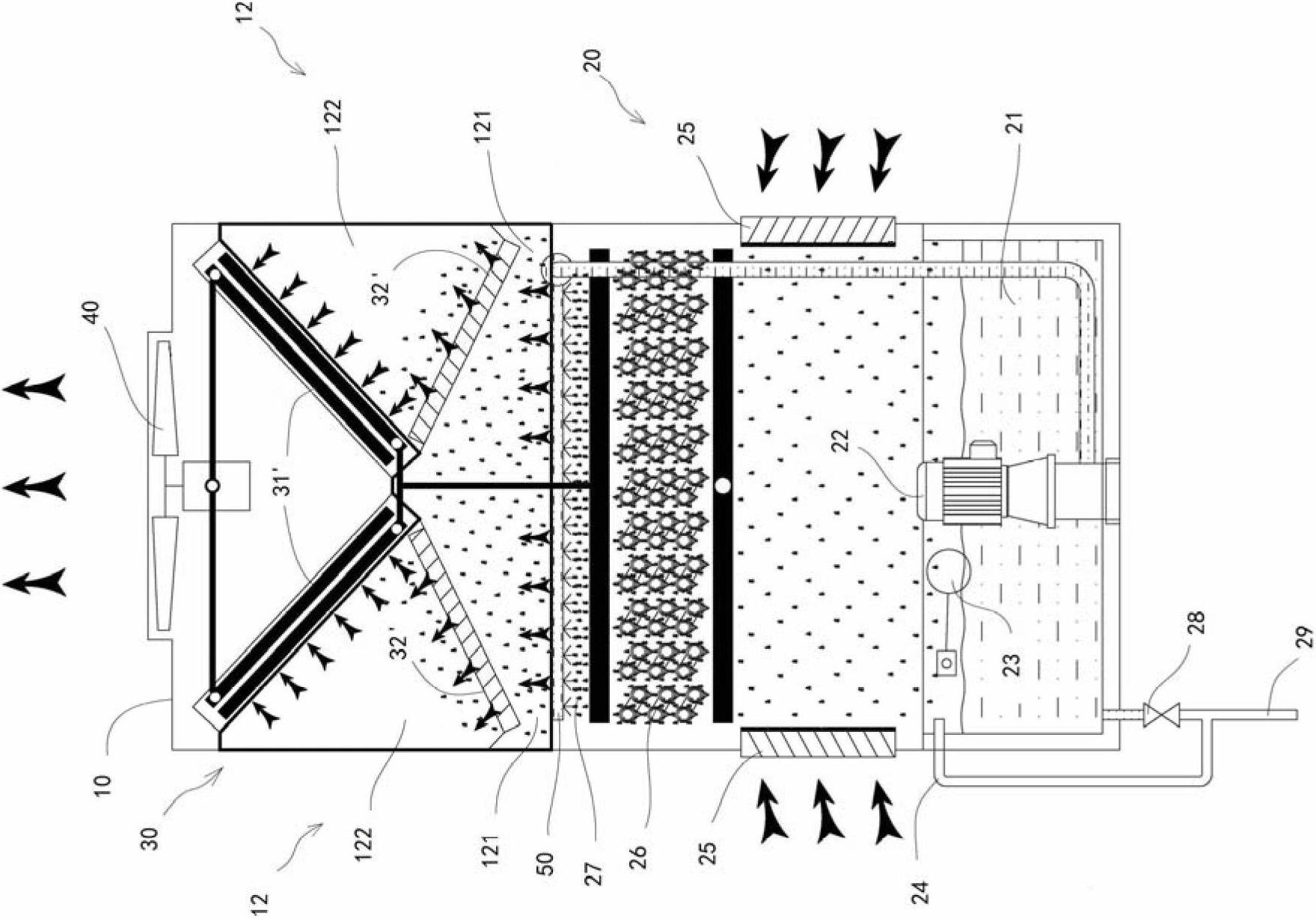

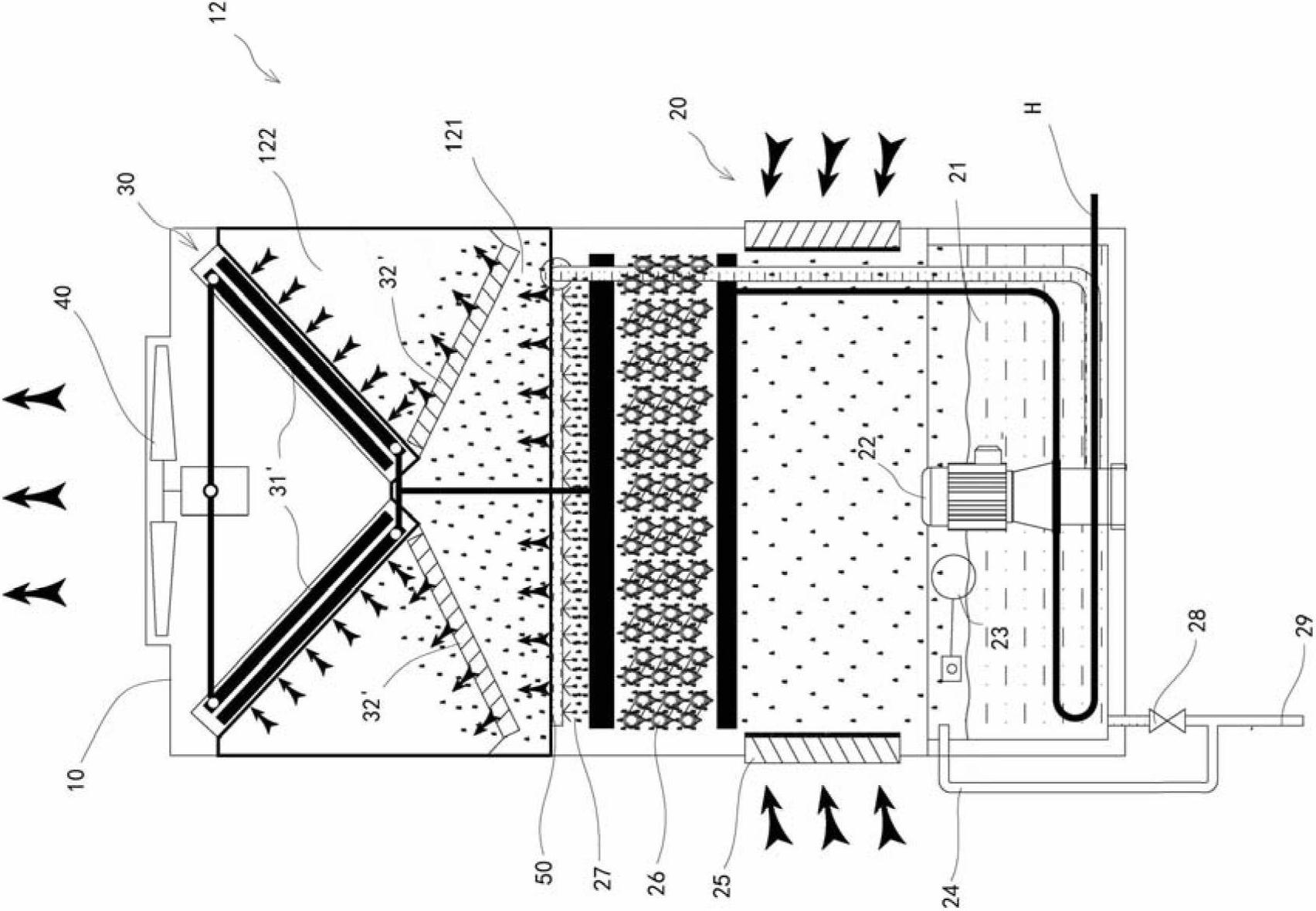

[0060] It can be seen from the previous overall implementation that the evaporative cooling heat exchanger in the upper section of the energy-saving fog-free evaporative condensation and cooling device uses the saturated water vapor generated by the lower evaporative condensation and cooling heat exchanger during the heat exchange process. And through the evaporative cooling heat exchanger in the upper section, the superheated steam is cooled into saturated gas, or the temperature of the high-temperature liquid is effectively reduced. This part of heat accounts for about 20-30% of the total heat exchange of the device, that is, the evaporative condensation and cooling exchange in the lower section The heat load of the heater is reduced by 20~30%. Since the circulating water volume and circulating air volume of the evaporative condensation and cooling device are calculated based on the evaporation, condensation and cooling heat transfer in the lower section, the circulating water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com