Perovskite solar cell with thermochromism performance and preparation method thereof

A solar cell and thermochromic technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of strong practicability, balanced indoor transmittance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

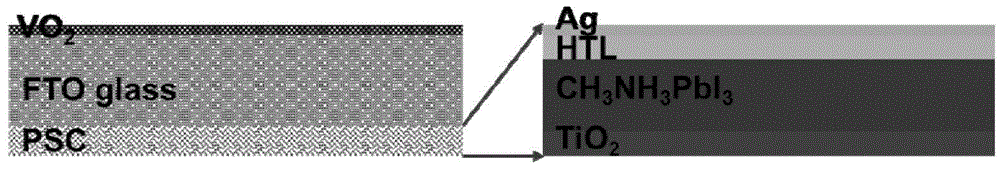

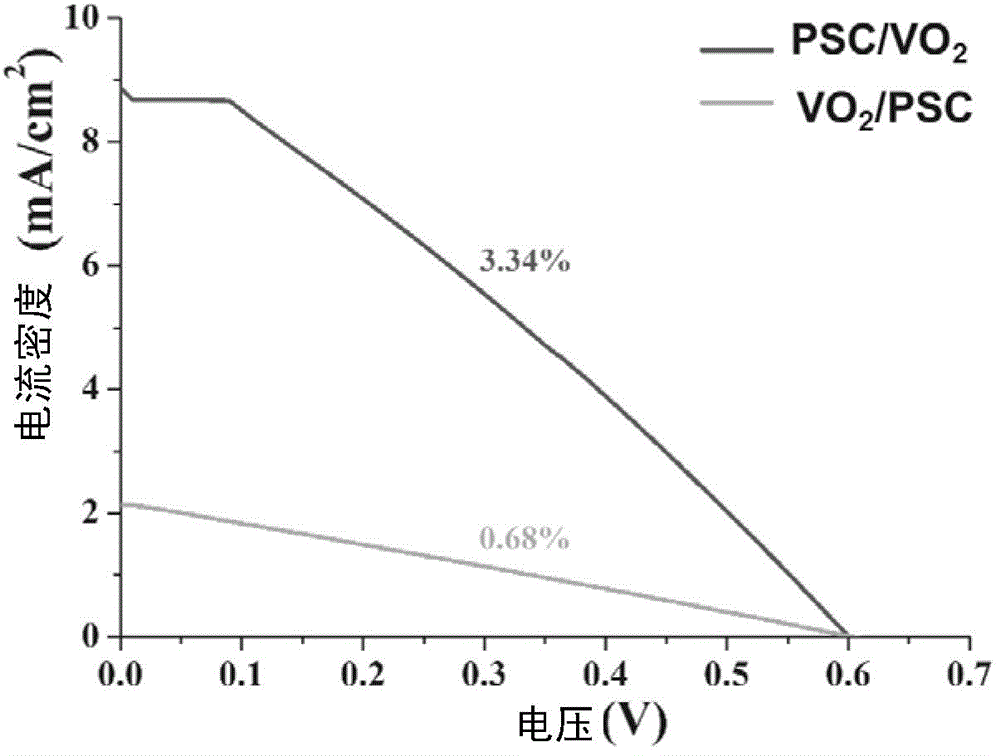

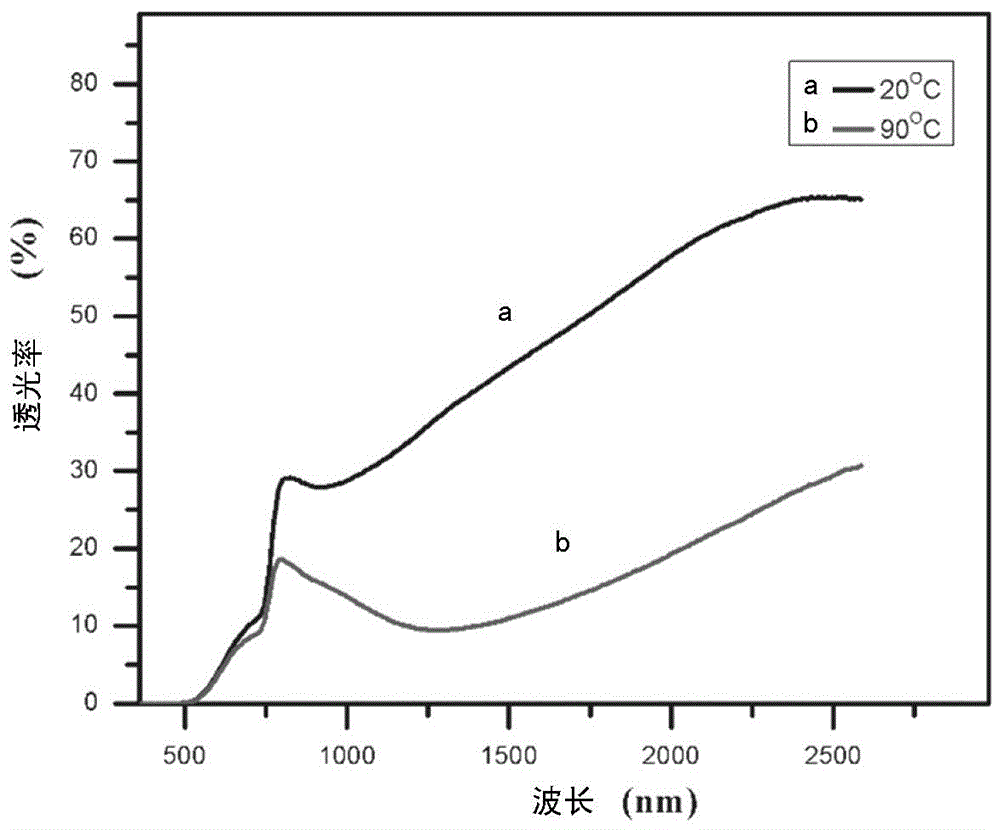

[0048] First, on the back of transparent conductive glass, deposit rutile phase vanadium dioxide slurry by spin coating at a speed of 1600r / min to prepare a vanadium dioxide film with a thickness of about 20 μm. After 1 hour treatment at 80°C, a dense rutile phase Vanadium oxide film. Second, perovskite solar cells were fabricated on transparent conductive glass. A dense titanium dioxide film was deposited on the surface of the conductive layer by magnetron sputtering, the air pressure was maintained at 1.5Pa, the ratio of argon to oxygen was 6:1, the sputtering power was 700W, and the sputtering time was 15min. Subsequently, a perovskite absorbing material with a thickness of 100 nm was prepared by dual-source co-evaporation, a hole transport layer with a thickness of 100 nm was prepared by spin coating, and finally the back electrode was deposited by vacuum evaporation with an evaporation current of 34 A and an evaporation time of 15 min. Finally, a perovskite solar cell wi...

Embodiment 2

[0050] First, on the back of the transparent conductive glass, the rutile phase vanadium dioxide slurry was deposited by spin coating to prepare a vanadium dioxide film with a thickness of about 20 μm. After being treated at 80°C for 1 hour, a dense rutile vanadium dioxide film was formed. Second, perovskite solar cells were fabricated on transparent conductive glass. A dense titanium dioxide film was deposited on the surface of the conductive layer by magnetron sputtering, and then a perovskite absorption layer and a hole transport layer with a thickness of 300 nm were sequentially prepared by dual-source co-evaporation and spin coating, and finally the back electrode was deposited by vacuum evaporation (See Example 1). Finally, a perovskite solar cell with thermochromic properties is obtained. The measured visible light transmittance of the perovskite solar cell with thermochromic properties is 13.7%. The measured photoelectric conversion efficiency of the perovskite solar...

Embodiment 3

[0052] First, on the back of the transparent conductive glass, the rutile phase vanadium dioxide slurry was deposited by spin coating to prepare a vanadium dioxide film with a thickness of about 20 μm. After being treated at 80°C for 1 hour, a dense rutile vanadium dioxide film was formed. Second, perovskite solar cells were fabricated on transparent conductive glass. A dense titanium dioxide film was deposited on the surface of the conductive layer by magnetron sputtering, and then a perovskite absorption layer and a hole transport layer with a thickness of 500 nm were sequentially prepared by dual-source co-evaporation and spin coating, and finally the back electrode was deposited by vacuum evaporation (See Example 1). Finally, a perovskite solar cell with thermochromic properties is obtained. The measured visible light transmittance of the perovskite solar cell with thermochromic properties is 9.26%. The measured photoelectric conversion efficiency of the perovskite solar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com