Surface protecting film for mobile phone screen at humid environment

A technology for surface protection films and mobile phone screens, applied in epoxy resin coatings, film/sheet adhesives, adhesive types, etc. Large and other problems, to achieve stable bonding, improve overall performance, and no adhesive residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

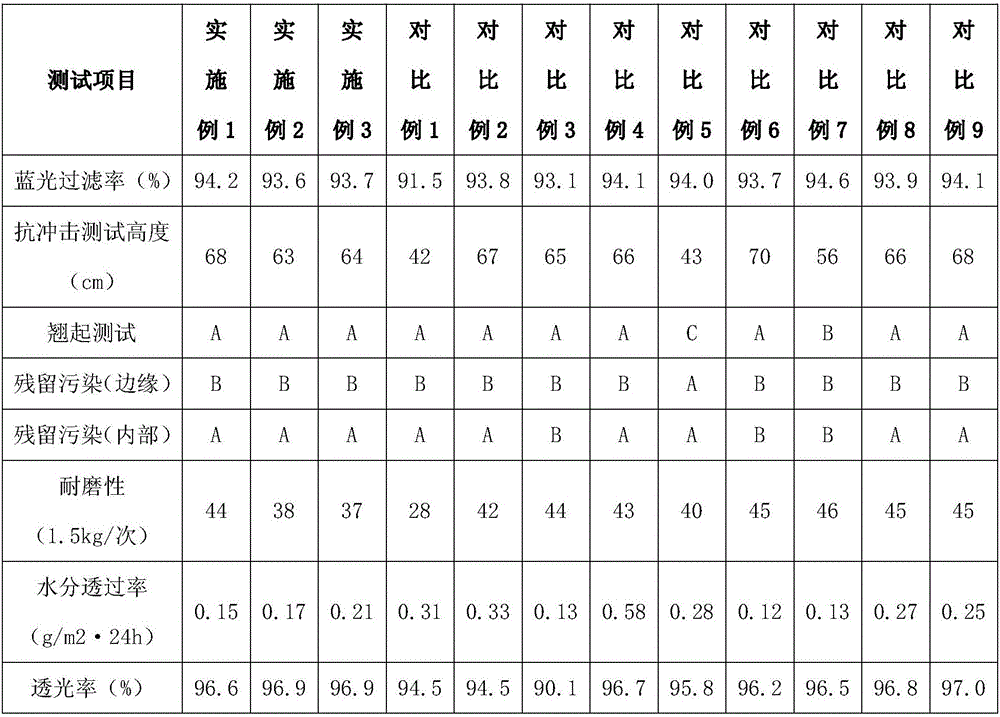

[0043] 1. Wear-resistant coating

[0044] Wear-resistant coating A Wear-resistant coating B Wear-resistant coating C Wear-resistant coating D epoxy acrylate 30 30 30 40 epoxy resin 10 10 10 0 Photoinitiator 0.7 0.7 0.7 0.7 Amine curing agent 1.8 1.8 1.8 1.8 leveling agent 0.7 0.7 0.7 0.7 Flake Titanium Dioxide 8 0 0 8 Spherical titanium dioxide 0 8 0 0 Nano Zinc Oxide 0 0 8 coupling agent 0.8 0.8 0.8 0.8 solvent 48 48 48 48

[0045] 2. Adhesive

[0046] Adhesive A1 Adhesive A2 Adhesive B1 Adhesive B2 Adhesive B3 urethane acrylate 30 30 25 25 25 Hydroxyl Acrylates 15 15 10 10 10 Water Absorbent Additive* 0.3 0 0.2 0.4 0 crosslinking agent 2 2 3 3 3 coupling agent 15 15 2 2 2 Photoinitiator 0.5 0.5 0.5 0.5 0.5 leveling agent 1.2 1.2 1.5 1.5 1.5 solvent 36 36.3 57.8 57.6 ...

Embodiment 1

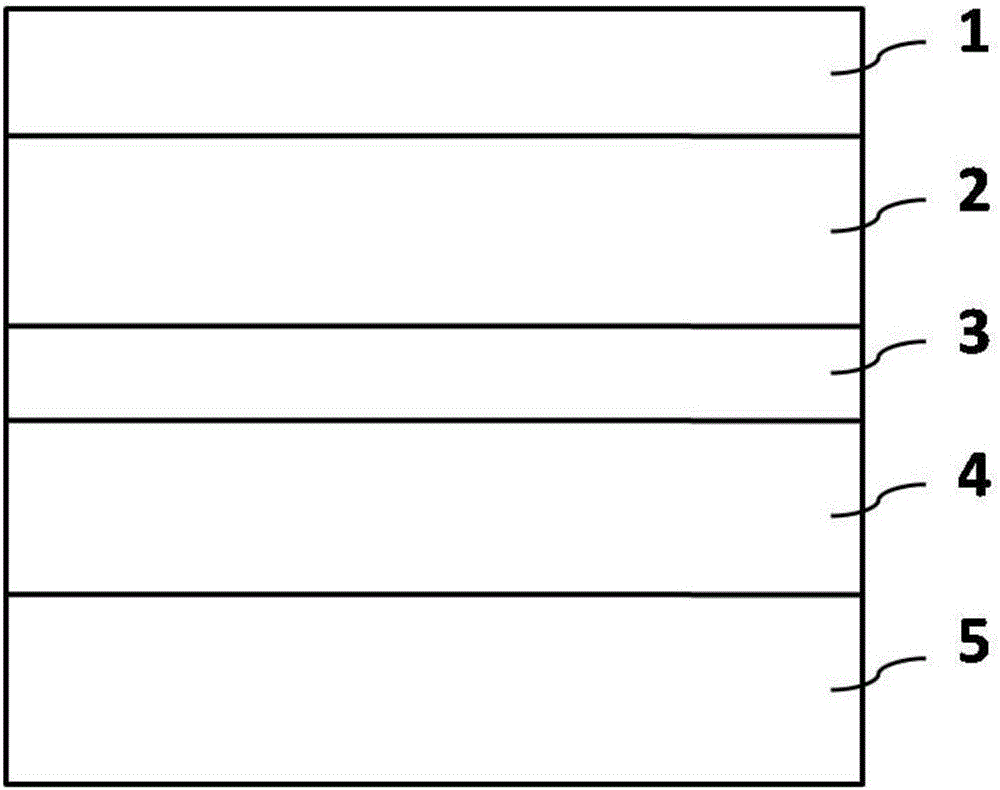

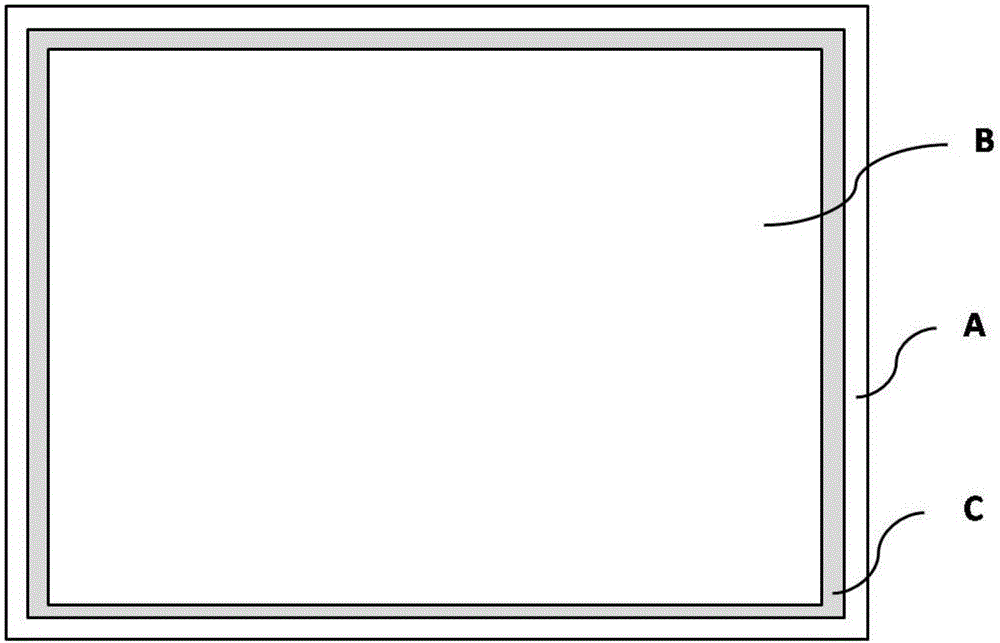

[0054] Coating wear-resistant coating A on the front side of a 160 μm thick PET film 2 containing 1.5 wt% calcium oxide and curing to obtain an 80 μm thick wear-resistant coating 1, coating the anti-blue light coating A on the reverse side and curing to obtain a 20 μm thick anti-blue light layer 3, Coating adhesive A1 (the area of the outer ring accounts for 10% of the area of the film layer) on the outer ring of the surface of the anti-blue light layer 3, and coating adhesive B1 on the inner area, the thickness of the adhesive layer is 90 μm, and the inner edge of the outer ring and There is a 0.1 mm wide annular gap between the outer edges of the inner region, and the surface of the adhesive layer is covered with a release liner with a thickness of 100 μm to obtain a surface protection film.

Embodiment 2-3

[0056] The wear-resistant paint B and C were used to replace the wear-resistant paint A in Example 1, respectively, to obtain a surface protection film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com