Mechanical devices and method of creating prescribed vibration

a mechanical device and vibration technology, applied in the direction of mechanical vibration separation, dynamo-electric converter control, motor/generator/converter stopper, etc., can solve the problem that the above-mentioned device cannot create certain desirable vibration profiles, the above-mentioned device cannot create a variety of selectable vibration profiles within limits, and the above-mentioned device cannot maintain a desired vibration profile. , to achieve the effect of reducing the difference between the measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

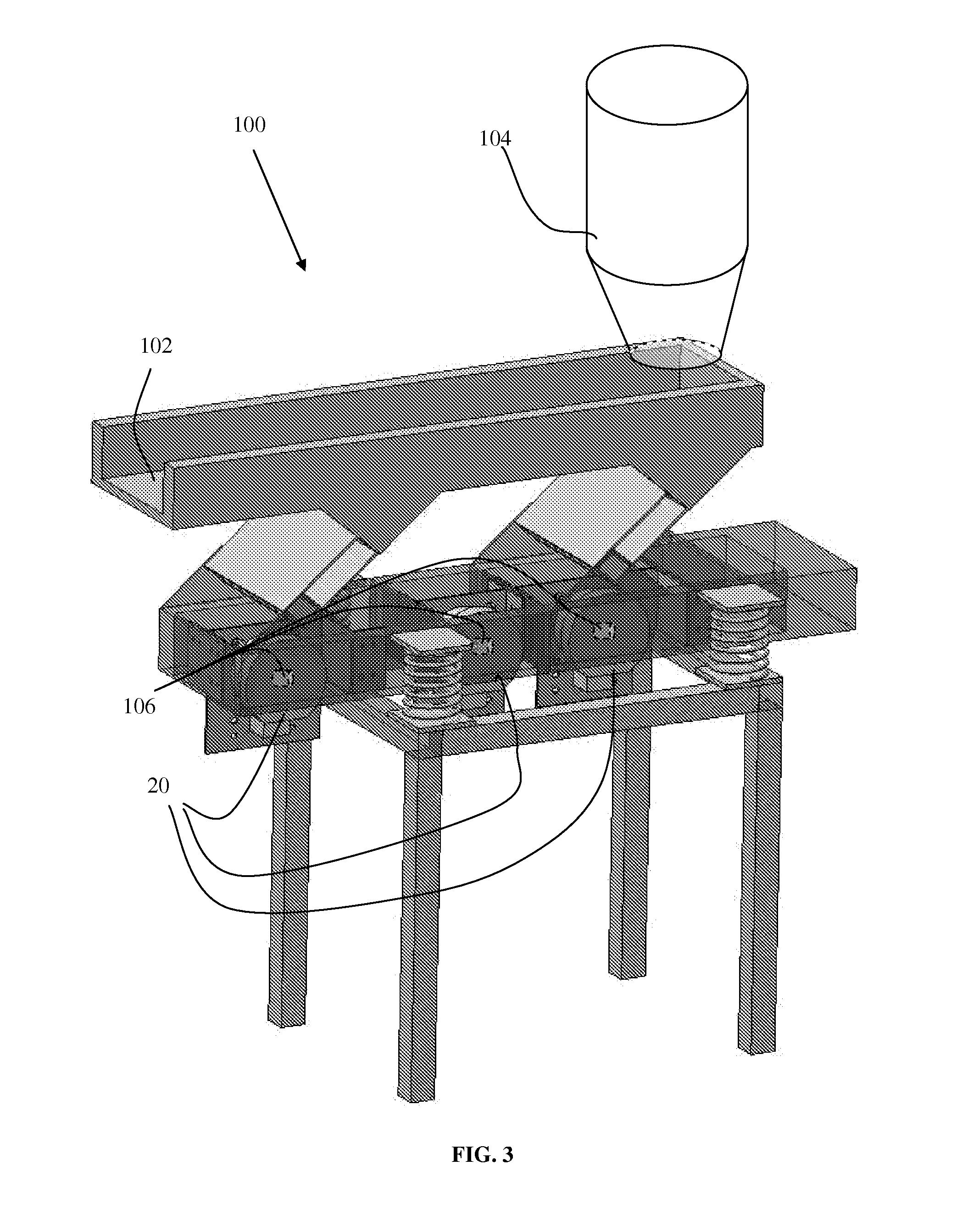

[0024]The invention described herein is applicable to a wide range of devices where a mechanically induced vibration is desired, the non-limiting examples of vibratory deliquifying machines, conveyors, and separators are used for illustration purposes.

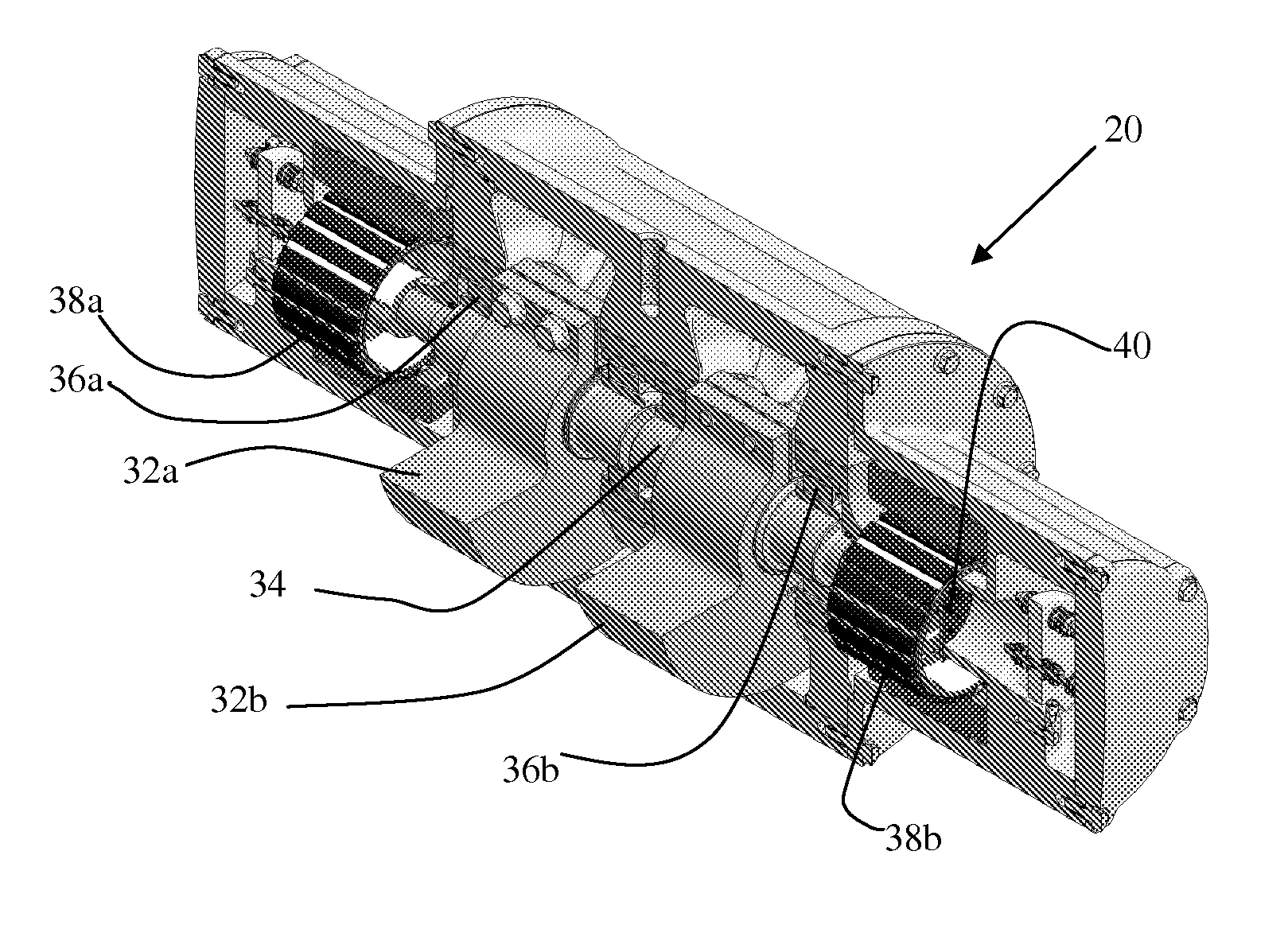

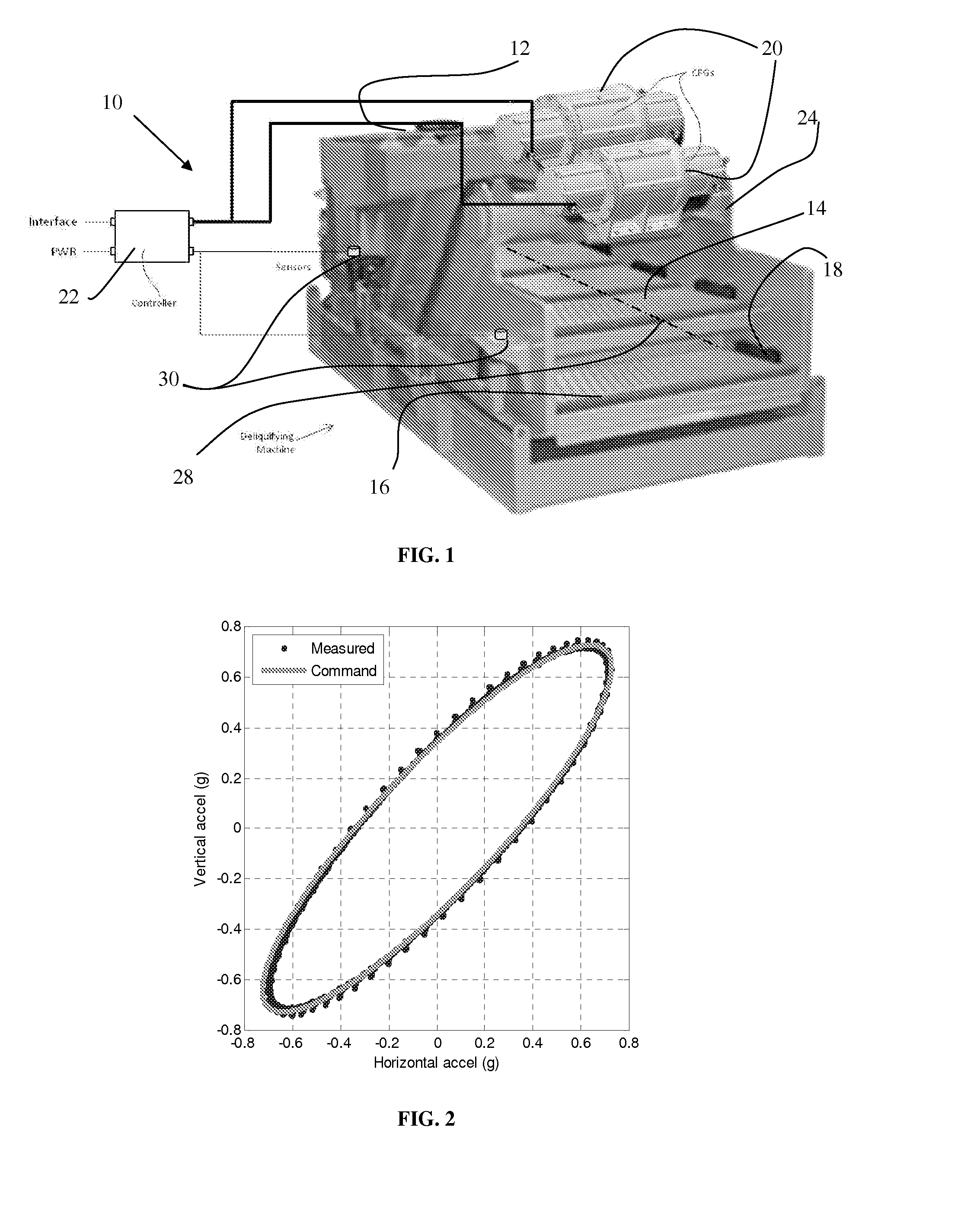

[0025]Referring to the drawings, FIG. 1 shows the invention as applied to the non-limiting example of a vibratory deliquifying machine illustrated and generally designated by the numeral 10. The non-limiting example vibratory deliquifying machine 10, as illustrated, includes inlet 12, screen 14, exit 16, springs 18, and force generators 20. Force generators 20 are preferably CFG 20.

[0026]In vibratory deliquifying machine 10, slurries (not shown) enter inlet 12 where a vibratory motion causes the slurry to convey across screen 14 suspended on springs 18. As the slurry is conveyed across screen 14, liquid passes through screen 14 while dry material (not shown) is extracted at exit 16.

[0027]Existing vibratory deliquifying machines 10 have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com