Long-term automatic online cable force monitoring system based on vibration method

A technology of monitoring system and vibration method, which is applied in the direction of tension measurement, force/torque/power measuring instrument, measuring device, etc., to achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

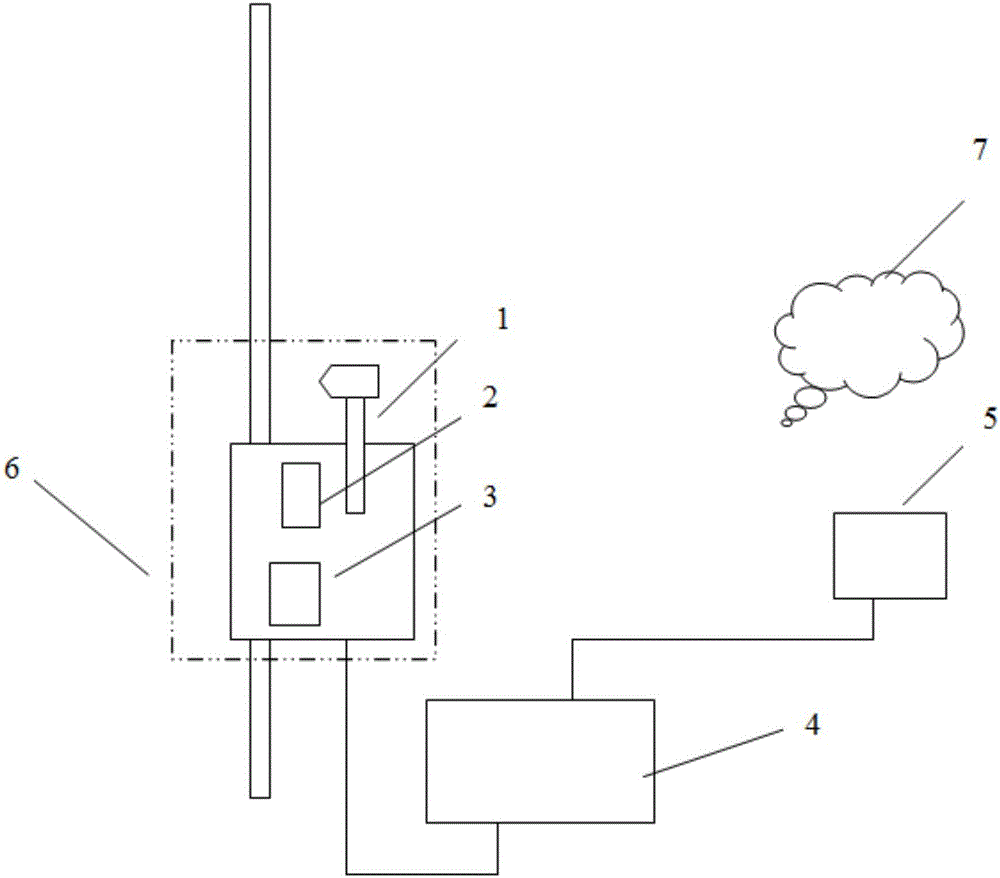

[0017] The connection topology diagram of a long-term automatic cable force online monitoring system based on the vibration method is as follows figure 1 As shown, the installation steps are as follows:

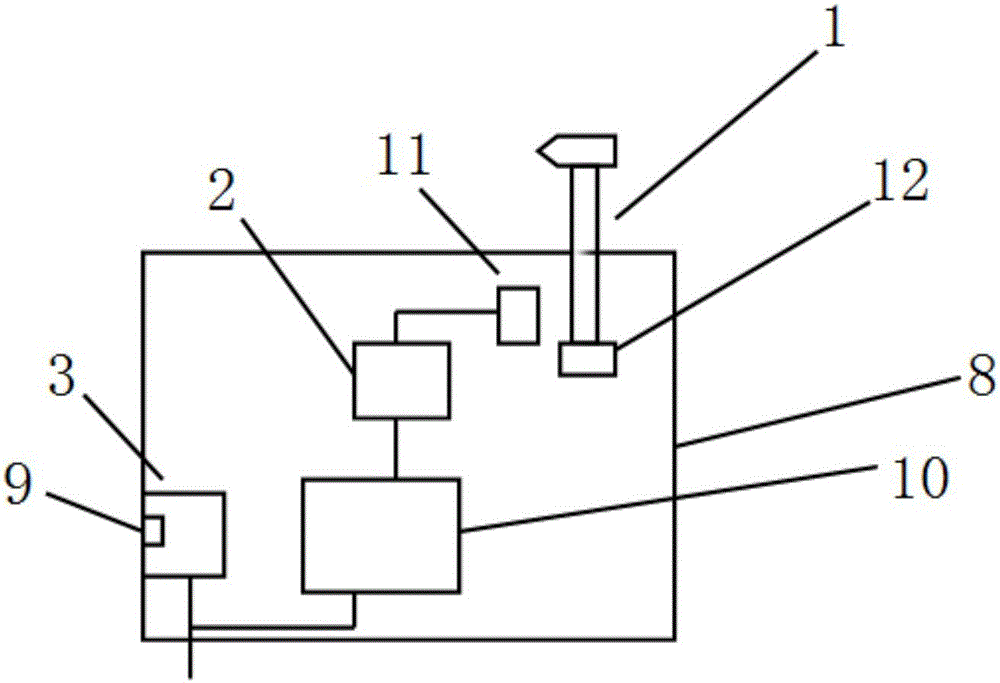

[0018] Fix the sensing module 6 with the cable under test by means of a hoop, and note that the installation position of the sensing module is 1 meter to 1.5 meters away from the fixed point at the lower end of the cable. The sensing module 6 includes: a hammer 1 , a relay 2 , and a vibration sensor 3 , and the relay 2 controls the hammer 1 .

[0019] Connect the signal cable of the sensing module 6 to the signal input end of the vibration collector 4 .

[0020] The 232 signal lines output by the vibration collector 4 are connected with the wireless data transmission module 5 .

[0021] Provide power to the vibration collector 4 and the wireless data transmission terminal 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com