Damping gap adjustable magnetorheological damper with series liquid flow channels

A magneto-rheological damper and liquid flow channel technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of increasing the axial size of the piston, increasing the overall size of the damper, and reducing damping The problem of the effective working stroke of the device is solved, and the damping force adjustment range is wide, the dynamic adjustment range is wide, and the working performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

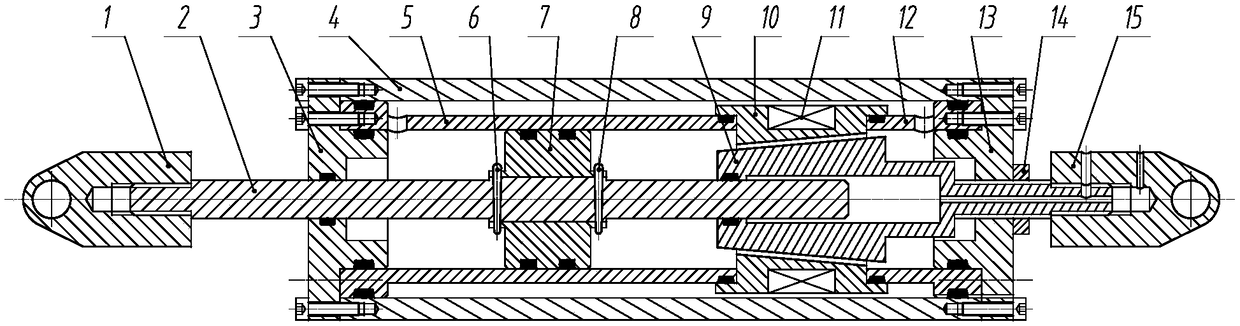

[0022] figure 1 Shown is the structure diagram of the present invention. It mainly includes: left lug 1, piston rod 2, left end cover 3, outer cylinder body 4, left inner cylinder body 5, left conical pin 6, piston head 7, right conical pin 8, valve core 9, bobbin frame 10, Exciting coil 11, right inner cylinder body 12, right end cover 13, lock nut 14 and right lifting lug 15.

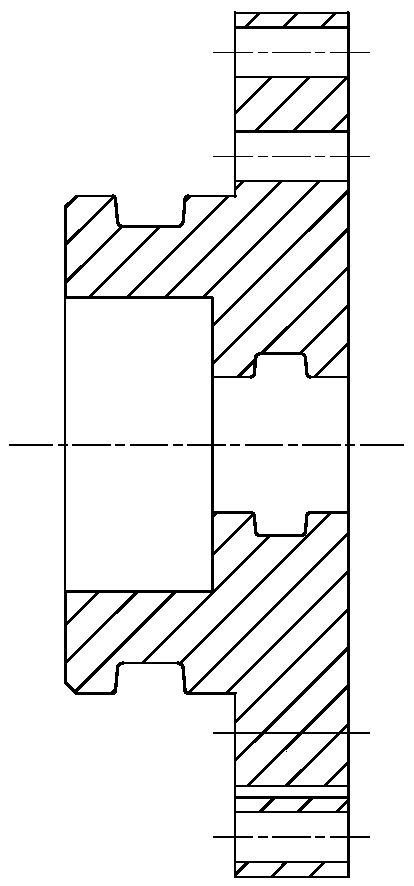

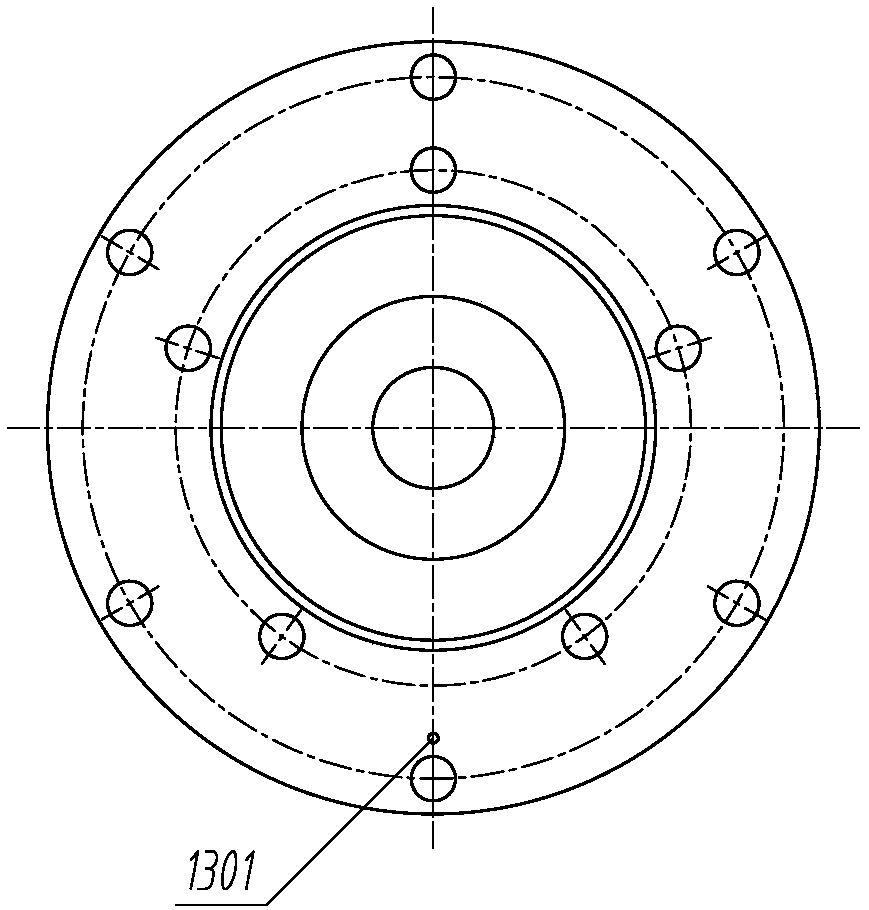

[0023] figure 2 Shown is the sectional view of the right end cover of the present invention, image 3 It is the left view of the right end cover of the present invention. The center of the right end face of the right end cover 13 is processed with a circular through hole, which can act as an axial positioning function for the left end of the piston rod 2; There are 6 threaded holes on the left end surface of the body 4, which can be used for positioning and connection with the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com