Bimetal composite pipe semi-finished product and machining method thereof

A bimetallic composite pipe, semi-finished product technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem of not providing operability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below:

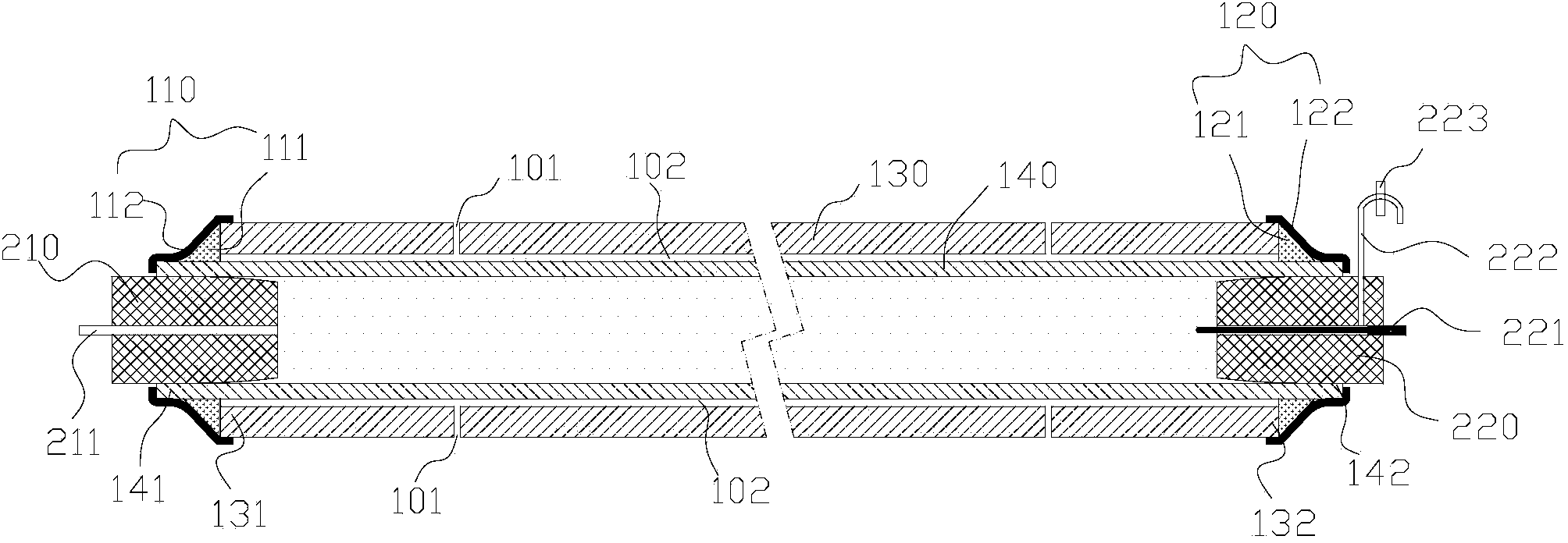

[0021] like figure 1 , a bimetal composite pipe semi-finished product, including a metal outer pipe 130 and a metal inner pipe 140, the metal outer pipe 130 and the metal inner pipe 140 have a first port and a second port respectively, and the metal inner pipe 140 is sleeved on the metal In the outer tube 130, there is a gap area 102 between the inner wall of the metal outer tube 130 and the outer wall of the metal inner tube 140, an air vent 101 is arranged on the metal outer tube 130, and a first port 131 of the metal outer tube and the first port of the metal inner tube Between the ports 141, between the second port 132 of the metal outer tube and the second port 142 of the metal inner tube, a first sealing device 110 and a second sealing device 120 are respectively provided. Plug 210, the first plug 210 is provided with a conduit 211, the conduit 211 conducts the inner cavity of the metal inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com