Adjustable offset moldboard plow

A conventional plow and offset technology, applied in the agricultural field, can solve problems such as easy subsidence, loose loam soil with hard lumps, and reduced flatness of sandy soil, so as to avoid potholes or small holes and improve flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

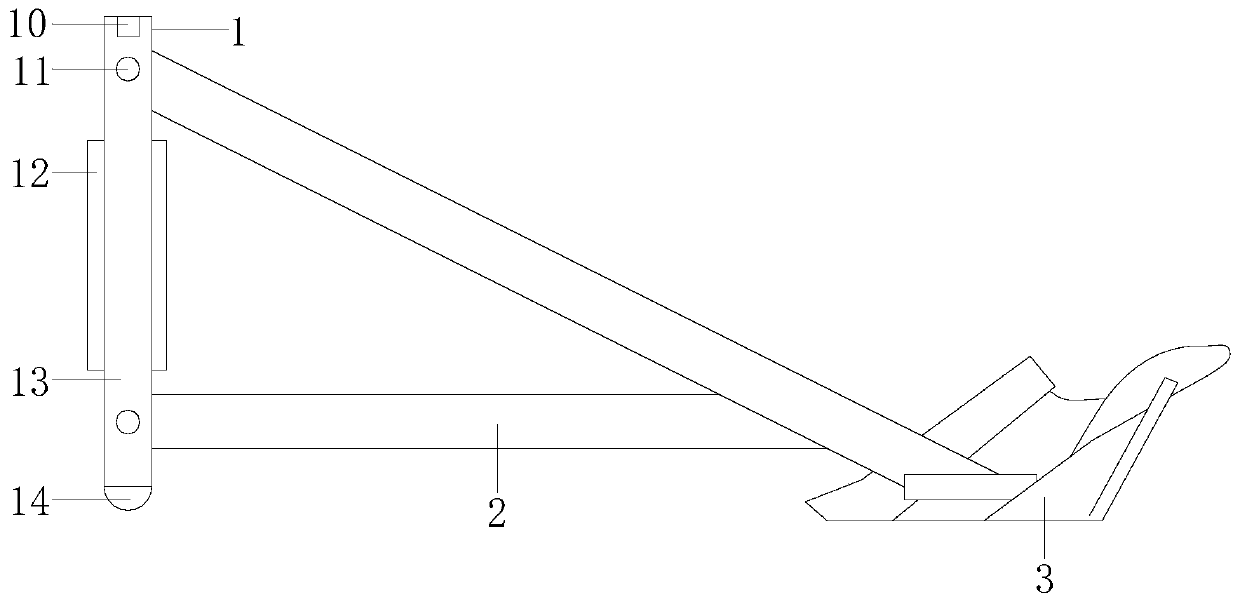

[0026] Example 1 see Figure 1-4 , the present invention provides a technical solution for an adjustable offset conventional plow: its structure includes a mounting plate 1, a frame 2, and a moldboard 3, the mounting plate 1 is locked with the frame 2, and the frame 2 It is installed and connected with the moldboard 3. The installation board 1 is composed of a belt buckle 10, a lock shaft 11, a mounting frame 12, a connection board 13, and a pad wheel 14. The pad wheel 14 is used for the movement of the auxiliary equipment. The wheel 14 has elastic force and can play the effect of buffering. The buckle 10 and the lock shaft 11 are installed on the connecting machine plate 13. The lock shaft 11 is to strengthen the locking of the transmission equipment and the installation machine plate 1. The belt buckle 10 is Strengthen the binding between the transmission equipment and the installation board 1, improve the transmission stability, the installation frame 12 is assembled and co...

Embodiment 2

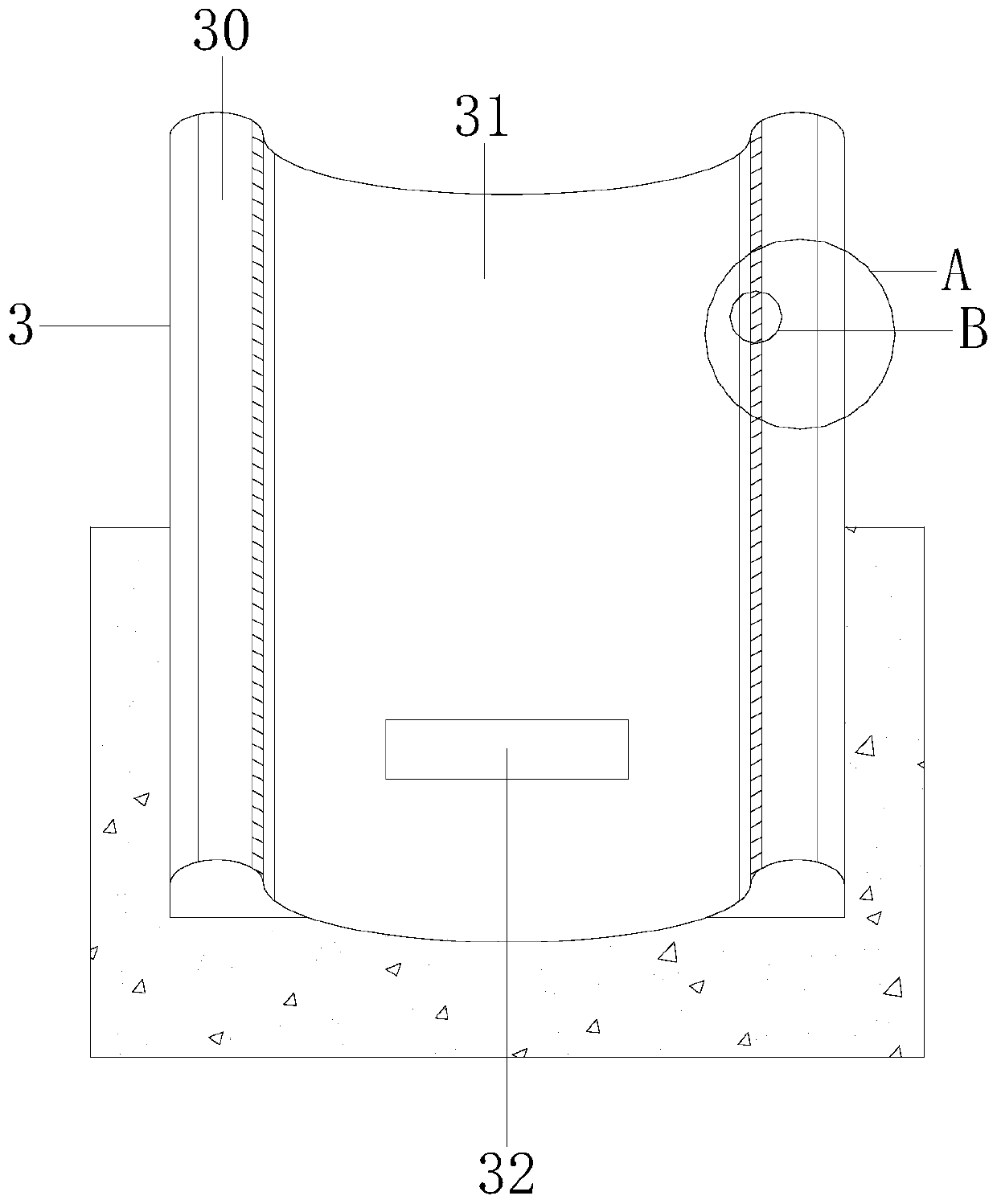

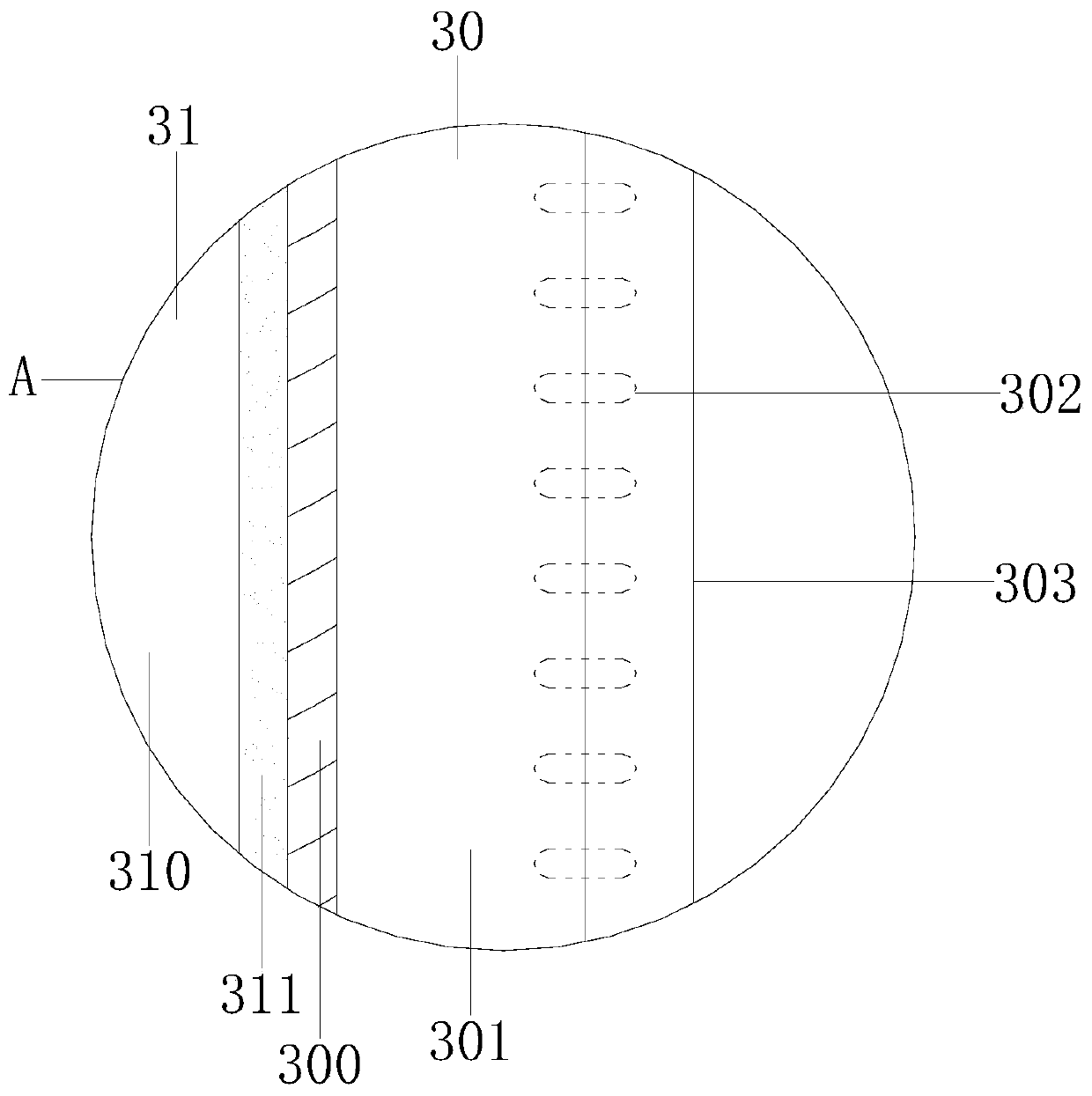

[0028] Example 2 see Figure 5-7 , the present invention provides a technical solution for an adjustable offset plow: the swing shaft structure 32 includes a square pad 320, an auxiliary transmission structure 321, a shaft body 322, and a shaft swing plate 323. The square pad 320 and The shaft swing plate 323 is glued, the auxiliary transmission structure 321 is welded to the shaft swing plate 323, the auxiliary transmission structure 321 is connected to the shaft body 322, and the auxiliary transmission structure 321 includes a latch 3210, a transmission belt 3211, and a spring 3212 , the latch 3210 is embedded and connected with the spring 3212, the latch 3210 is connected with the transmission belt 3211, the latch 3210 is equipped with a bolt rod 400, the movement of the bolt rod 400 controls the tightness of the spring 3212, The elastic force of the spring 3212 changes the swing force of the moldboard 3, reasonably controls the swing distance of the moldboard 3, and reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com