Coil type sludge sampling and activity evaluation device for anaerobic reactor and working method thereof

An anaerobic reactor and sludge technology, applied in sampling devices, measuring devices, sampling and other directions, can solve the problems of potential safety hazards, limited sampling range, harsh sampling environment, etc., to achieve comprehensive sludge sampling and avoid duration The effect of long and accurate assessment of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

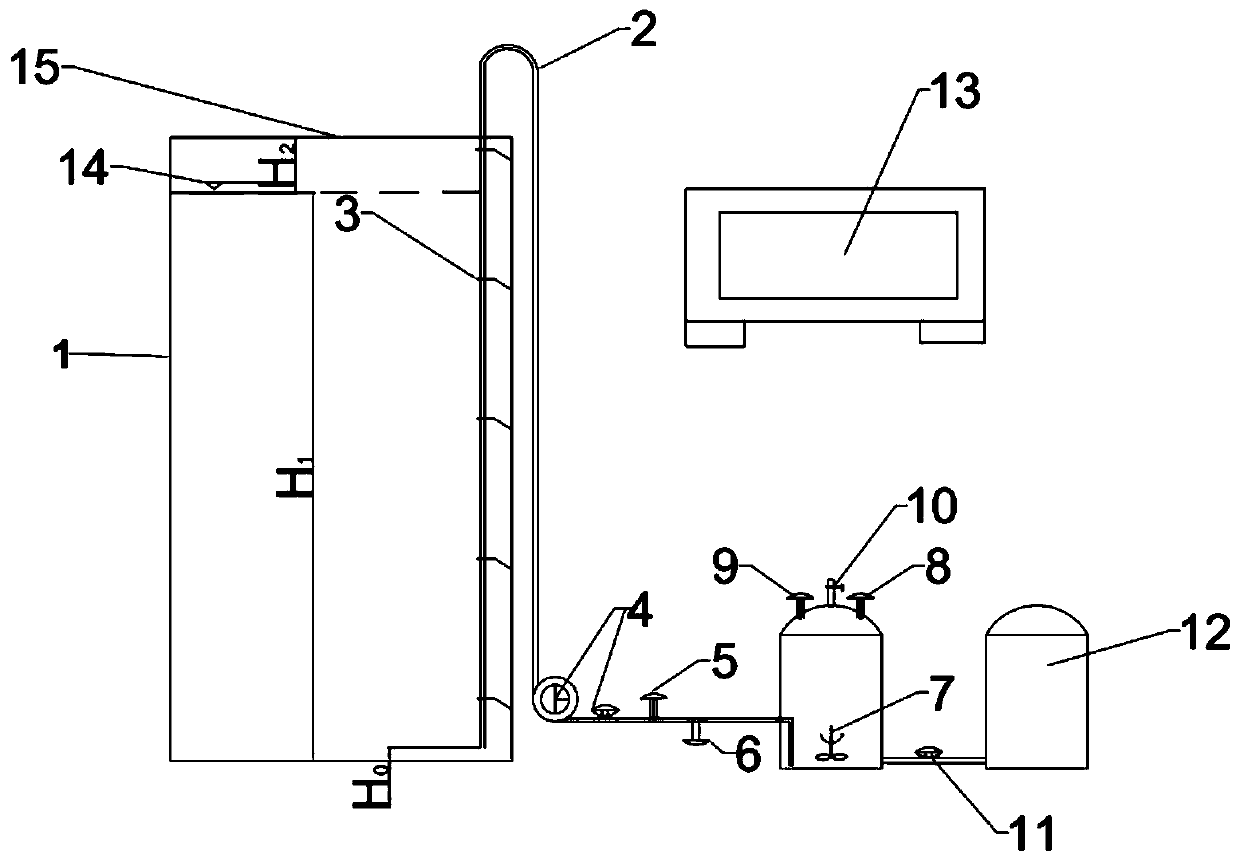

[0038] Such as figure 1 As shown, a coiled tube sludge sampling and activity evaluation device for anaerobic reactors, including a coiled tube sampling system, a sludge testing system and a PLC control system;

[0039] The coiled tube sampling system includes an anaerobic reactor 1, a stainless steel hose 2, a support frame 3, a positive and negative constant speed coiler-a metering pump 4, the support frame 3 is connected to the side wall of the anaerobic reactor 1, and the stainless steel soft tube The pipe 2 is connected with the positive and negative constant speed reel-metering pump 4 and can move up and down along the support frame 3;

[0040] The sludge testing system includes a density meter 5, a pH / T tester 6, a storage reaction tank 7 with an agitator, a pressure gauge 8, a methane / carbon dioxide concentration tester 9, a biogas discharge pipe 10 with a control valve, and a metering Pump 11, detection liquid storage tank 12; the stainless steel hose 2 passing throug...

Embodiment 2

[0051] As described in Example 2, a certain papermaking enterprise, according to the relevant indicators of sewage, is in accordance with the Environmental Protection Standard of the People's Republic of China HJ-2013-2012 "Technical Specifications for Upflow Anaerobic Sludge Bed Reactor Sewage Treatment Engineering / Technical specifications of up-flowanaerobicsludgeblanket (UASB) ) UASB anaerobic reactor designed by "reactorforwastewatertreatment"

[0052] the difference is:

[0053] The UASB anaerobic reactor is a reinforced concrete structure. During the normal operation of the UASB reactor, the water surface height is 6.5m, and the reactor height is 7m. When the stainless steel hose is not working, the vertical height from the bottom of the anaerobic reactor is 0m. Empty and stir The volume of the storage reaction tank 7 of the device is 650L.

[0054] The relevant sludge properties that present embodiment 2 obtains and active test result are as follows:

[0055] (1) Du...

Embodiment 3

[0060] As described in Example 1, a beer company, according to the relevant indicators of sewage, is in accordance with the environmental protection standard of the People's Republic of China HJ-2023-2012 "Technical Specifications for Wastewater Treatment Engineering of Anaerobic Granular Sludge Expanded Bed Reactor" designed steel structure EGSB anaerobic Oxygen reactor; the water surface height of this EGSB reactor is 20.5m during normal operation, and the reactor height is 21m. When the stainless steel hose is not working, the vertical height from the bottom of the anaerobic reactor is 0.5m. Empty the storage reaction tank of the agitator 7 has a volume of 2000L, and the volume of the storage reaction tank 7 that empties the agitator is 2000L.

[0061]Sludge sampling process: Turn on the positive and negative constant-speed hose reel-metering pump 4 to drive the stainless steel hose 2 to move upward along the support frame 3 at a speed of 1m / s and simultaneously extract the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com