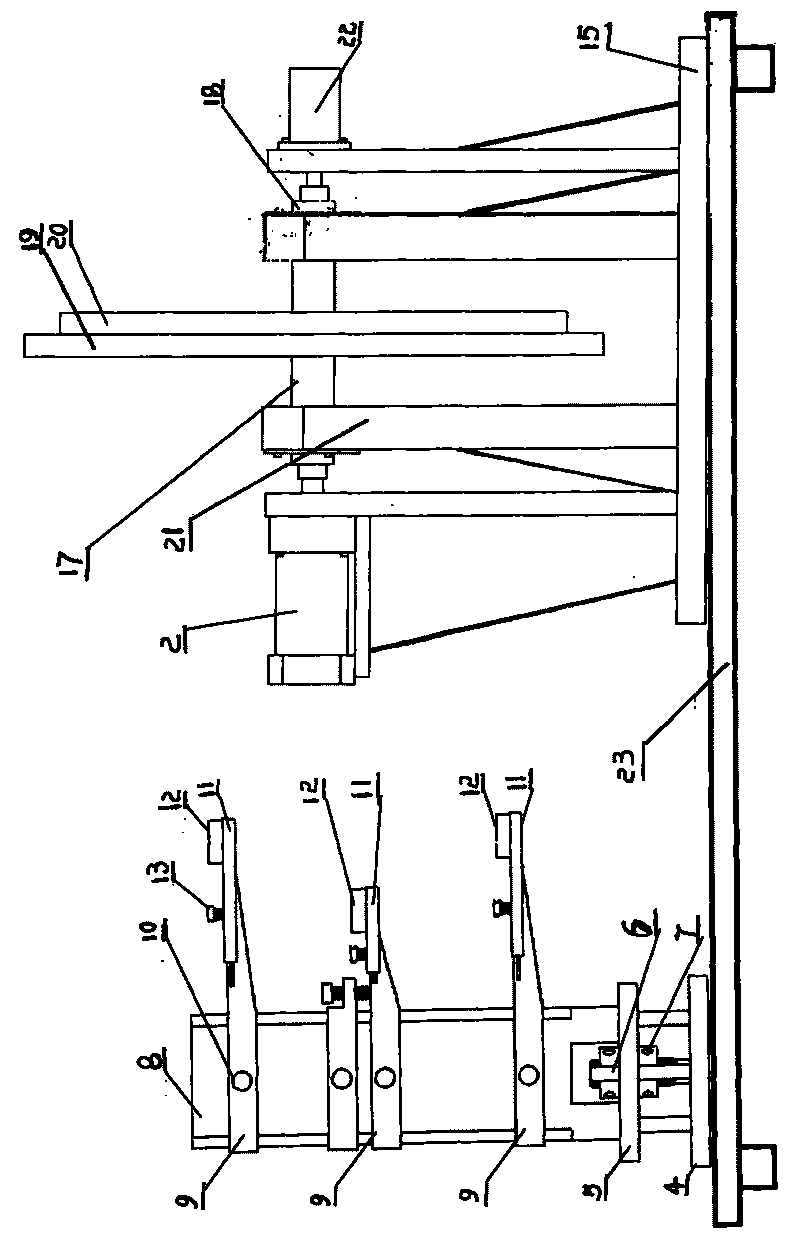

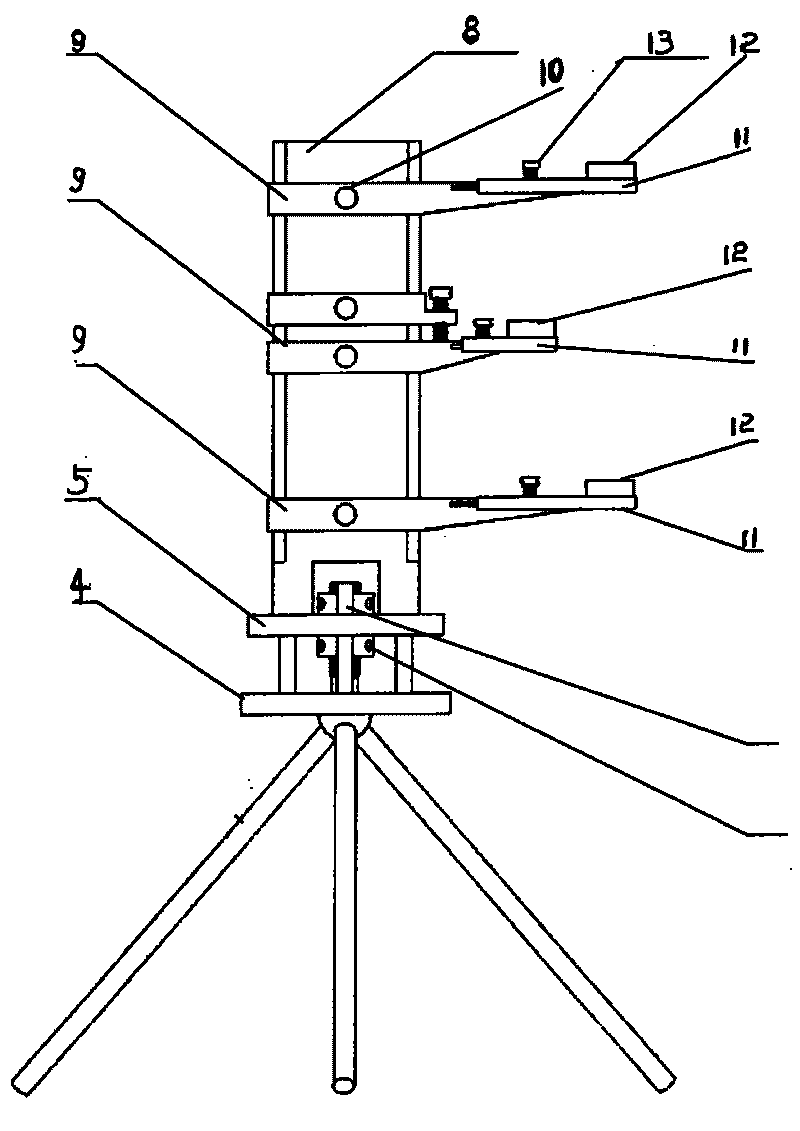

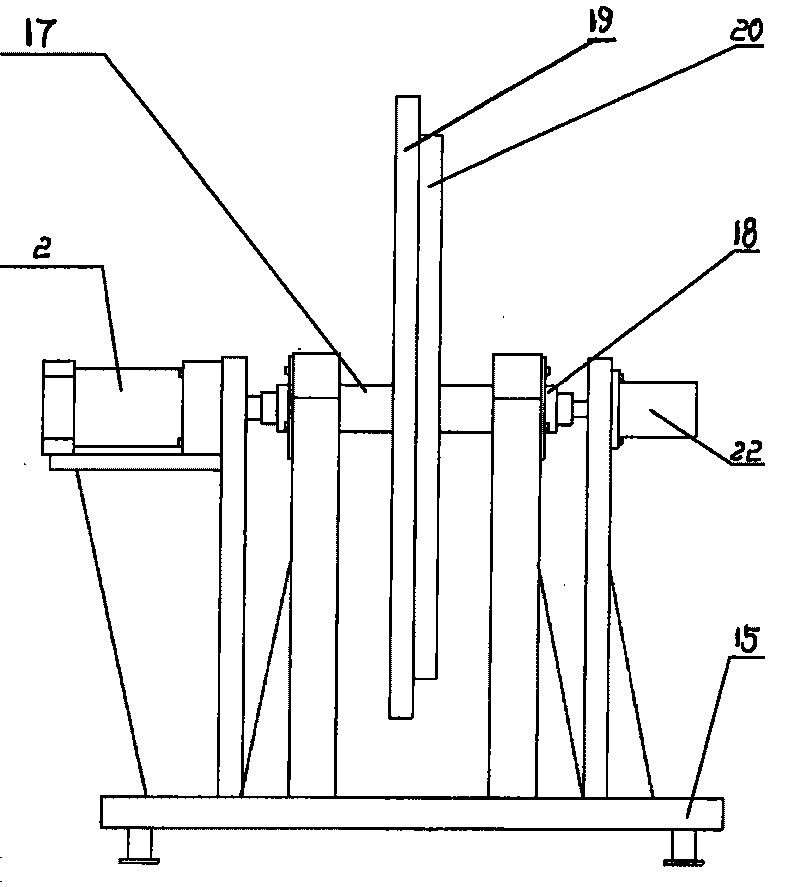

Device for measuring diameter of large shaft working piece by non-contact-type online measurement

A workpiece diameter, non-contact technology, used in measuring devices, optical devices, instruments, etc., can solve the problems of complicated instrument structure and signal processing process, and achieve the effect of simple structure, scientific design and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] It is required to measure the size of the large axis with a diameter of 505mm, and the LK-G30 laser displacement sensor (12) is selected. The working distance is 30mm, and the measurement range is -5mm-5mm. Compared with the ML10 laser interferometer, the measurement accuracy is 1μm about. The chord length is selected as 400mm, and the diameters of the calibrated large discs are respectively taken as 508mm and 500mm.

[0030] Three sizes of outer discs are processed on a large disc, and calibrated on a three-coordinate measuring machine. The upper, middle and lower sections of each size of the circle are measured respectively, and the diameters and roundness of the three outer circles are obtained as follows As shown in the table:

[0031]

Diameter (mm)

Roundness (μm)

round one

499.786

499.789

499.791

26.3

9.9

15.5

round two

503.600

503.601

503.605

13.7

12.4

17.7

roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com